1、STRUCTURE, FEATURES AND USAGE

This lathe adopts full gear transmission with great stability and high tooling

accuracy. The main spindle speed changing unit –diprosopia curves disc, and

longitudinal/cross feeding safety unit are own patented. The full functioned

lathe with longitudinal/cross auto-feeding can realize tooling speeds choosing

and regular threads setting through feeding box.

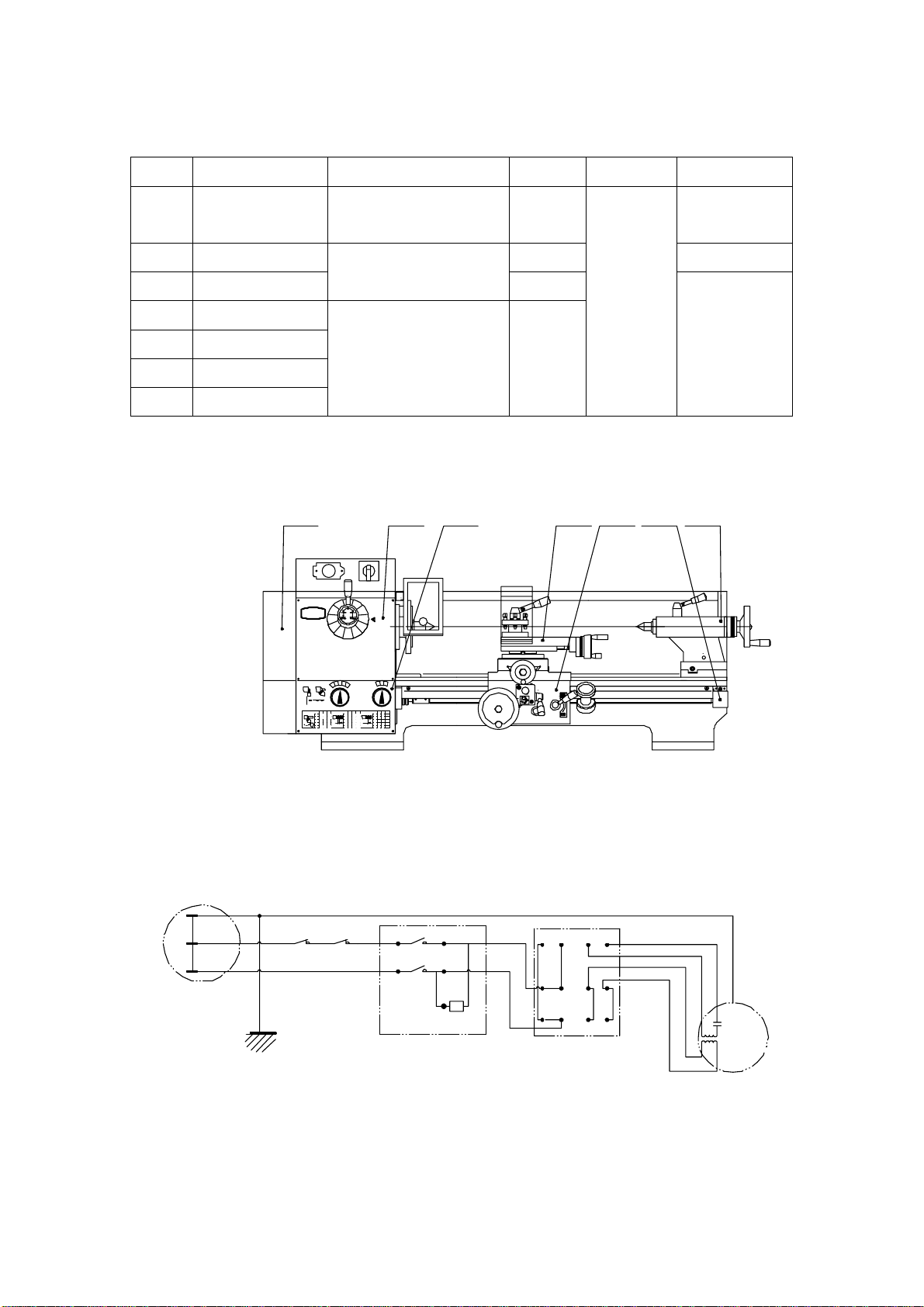

1

2

C

B

A

1

2

3

4

5

A B C A B C A B C

5

4

3

2

1

5

4

3

2

1

5

4

3

2

1

0.50 1.00 2.50

0.40

0.35

0.30

0.25

0.80

0.70

0.60

0.50

2.00

1.75

1.50

1.25

48 24

60 30 12

80 40 16

96 48

mm n/1″

mm

CJM250

0.035 0. 070.175

0.045 0. 090.225

0.050. 100.25

0.060. 120.30

0.075 0. 150.375

O

F R

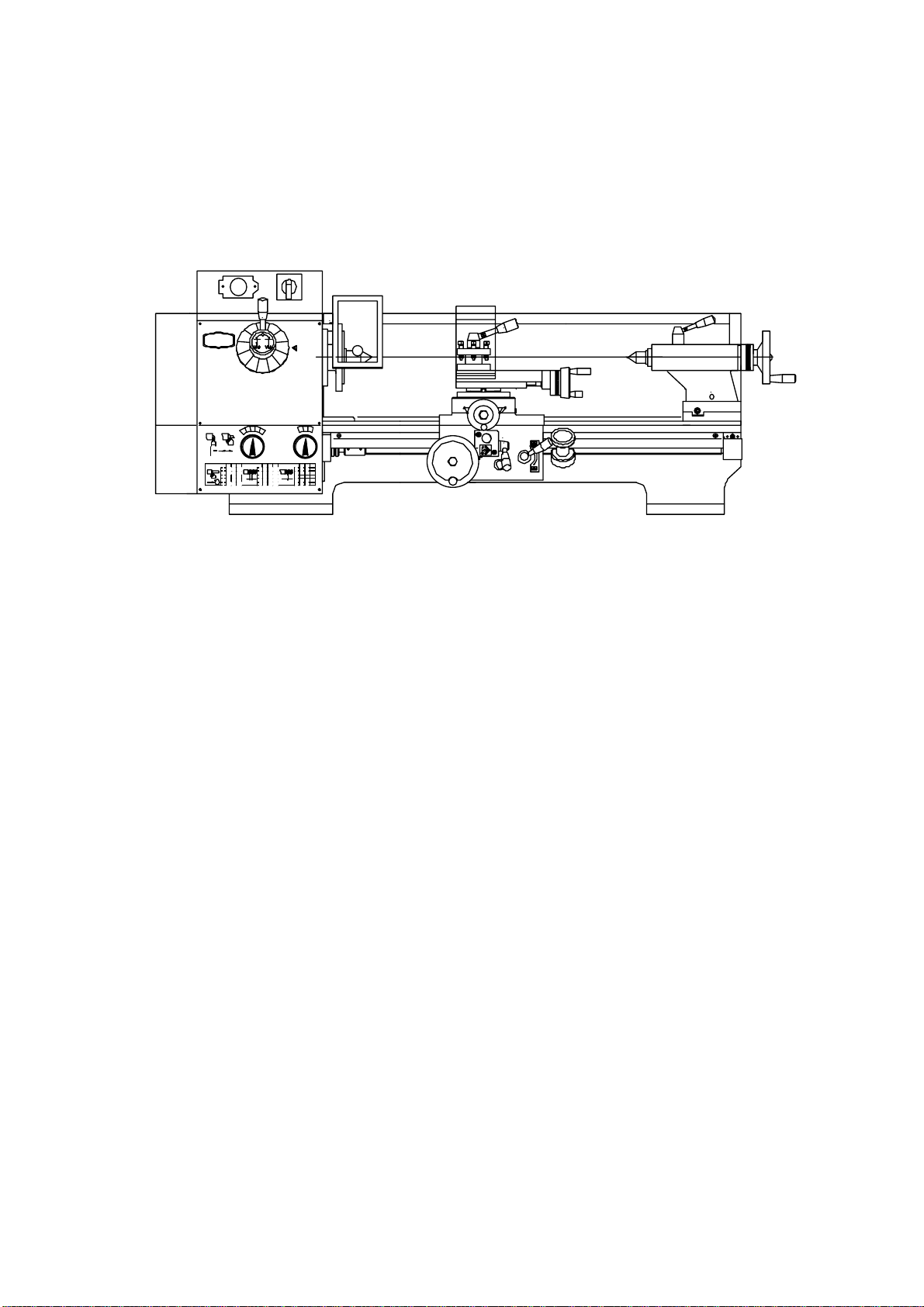

Picture 1 OVERVIEW

) Headstock Full gear driven, the spindle speed changing is achieved

through sliding gears and the main spindle can get 12 kinds of speeds

at wide range.The lathe has the structure of forward/reward feeding

unit which can get auto feeding in both direction and make right/left

threading.

) Gearbox Transmit the movement in headstock to feeding box through

change gears. By choosing different change gears, different

metric/imperial threading can be achieved.

) Feeding box It has 15 shifts. There is no need of changing the gears

to get 15 kinds of feeding speed and tooling 15 kinds of

metric/imperial threads.

)Carriage It has longitudinal/cross feeding interlock unit which

can make auto feeding in longitudinal or cross direction.

) Bedway The bedway adopts two V guideways, ensuring perfect

positioning accuracy and excellent tooling rigidity.

)Tailstock

It adopts rapid cam-lock unit to make easy and rapid operation.

) Standard accessories

Three jaw chuck, dead center, toolpost wrench, inner hexagon spanner,

stud dead spanner, change gears, splash guard

) Optional accessories for your choice

Machine stand, steady rest, follow rest, oil tray, toolcutter set,

live center, face plate, four jaw chuck, backplate, special gears.