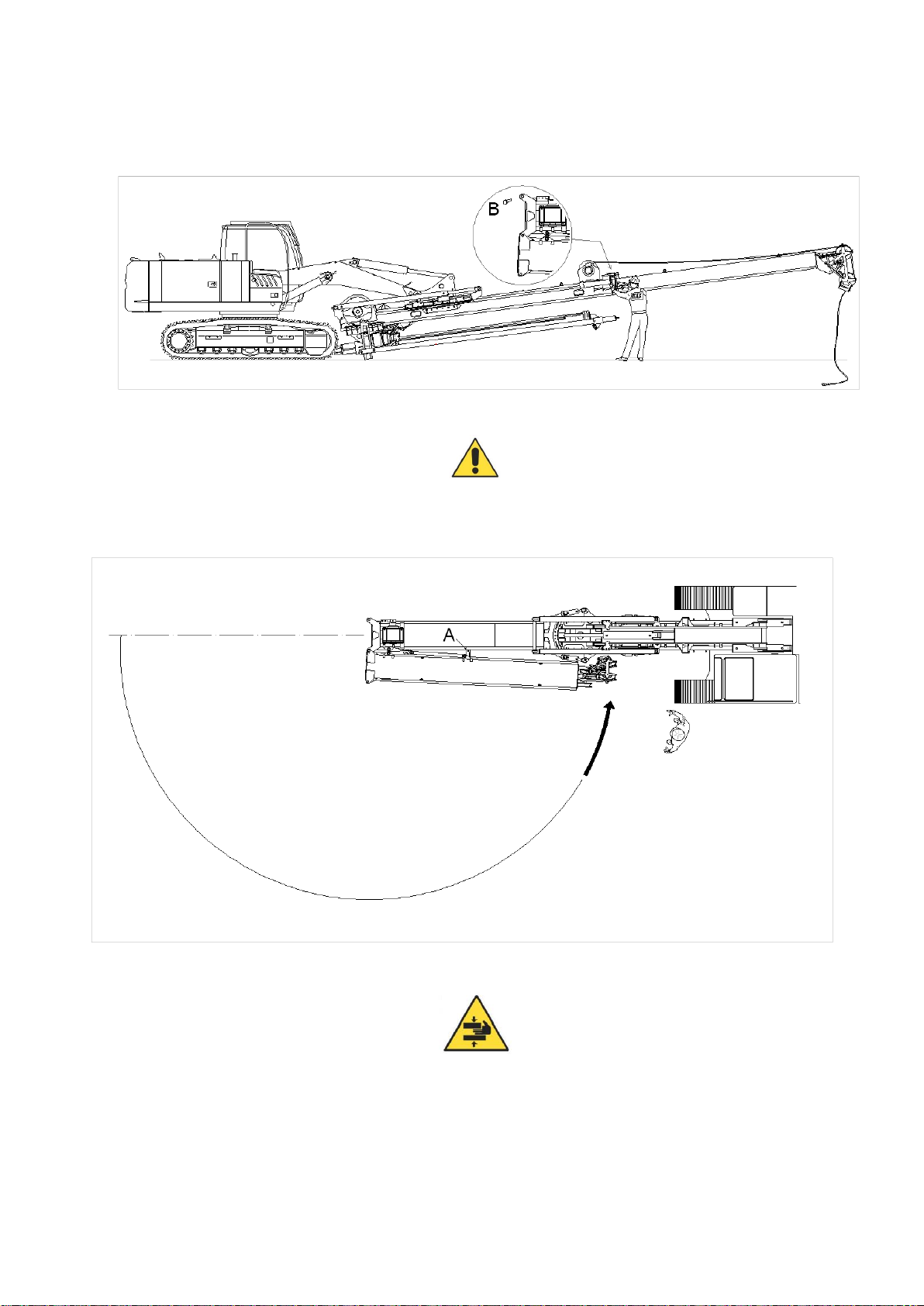

Hook the tool (lower element) to the rope of the secondary winch.

Command a slight tensioning of the rope.

Loosen the recessed safety bolt and slip the pin off.

Climb down the ladder and remove it.

Go to a safe area.

Lift the rotary-tool so that the joint slips off and the auger part remains

hanging on the rope of the winch.

Move the rope of the secondary winch down.

Place the tool on the ground and move it.

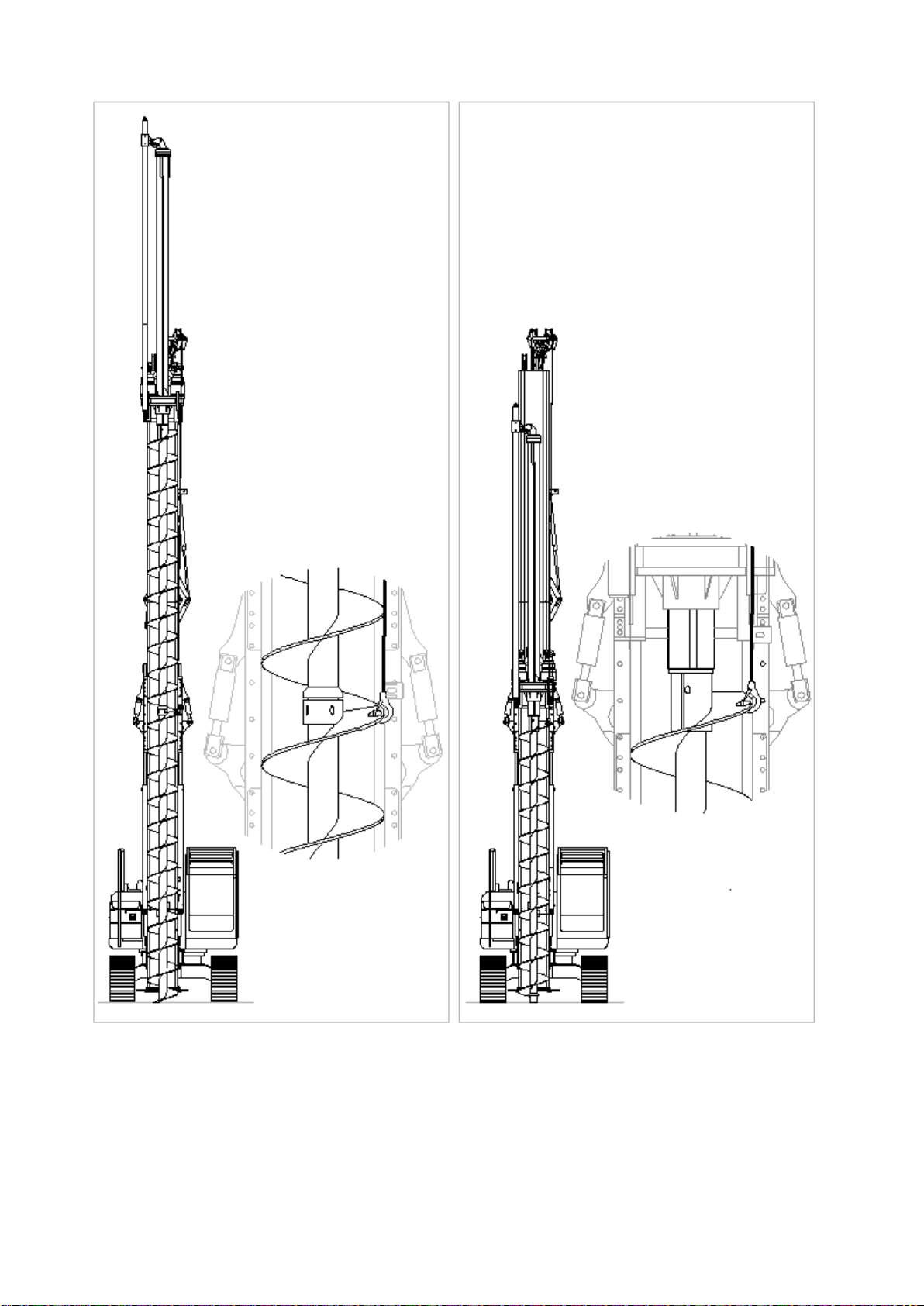

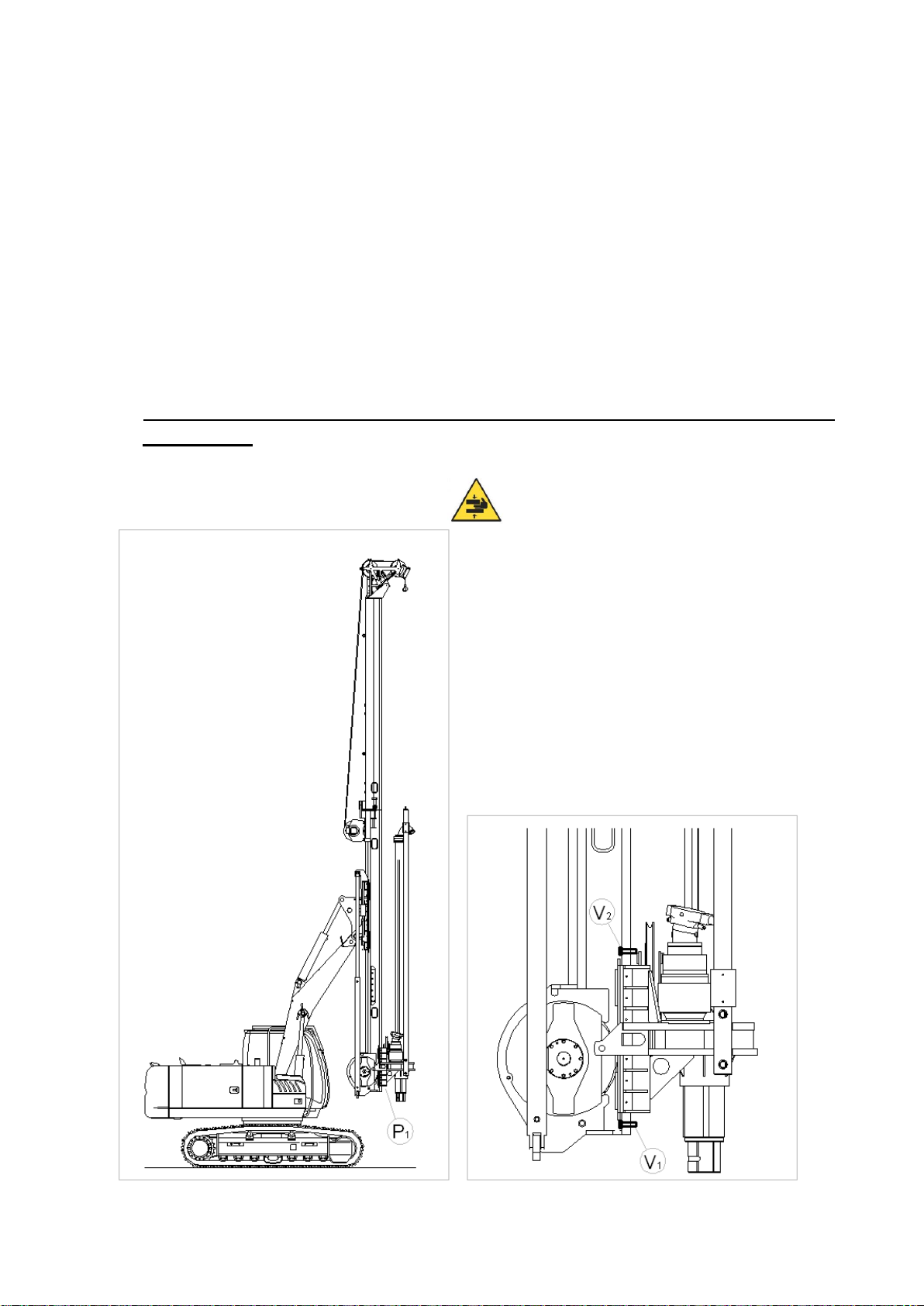

Proceed as follows to disassemble the upper part of the auger fig.2.1.1.2:

Rest the tool on the ground, moving the rotary to the intermediate

position.

Lean the ladder against the mast.

When a second operator at the base guarantees the stability of the

ladder by holding it with both hands, climb up to the height of the rotary

joint and secure the safety belts to the eyebolt on the mast.

Hook the tool (upper element) to the rope of the secondary winch.

Command a slight tensioning.

Loosen the recessed safety bolt and slip the pin off.

Climb down the ladder and remove it.

Go to a safe area.

Lift the rotary-shaft so that the joint slips off and the auger remains

hanging on the rope of the winch.

Move the rope of the secondary winch down.

Place the tool on the ground and move it.