Contents

2

Contents

Contents...............................................................................................2

Important safety information .............................................................4

Intended use .........................................................................................4

Qualification of the staff ........................................................................4

Warning notices in these instructions ...................................................5

Further documents................................................................................5

Pay particular attention to..................................................................5

General instructions..............................................................................5

Installation.............................................................................................6

Operation ..............................................................................................6

Cleaning................................................................................................6

De-installation .......................................................................................6

Disposal ................................................................................................6

Scope of delivery ................................................................................7

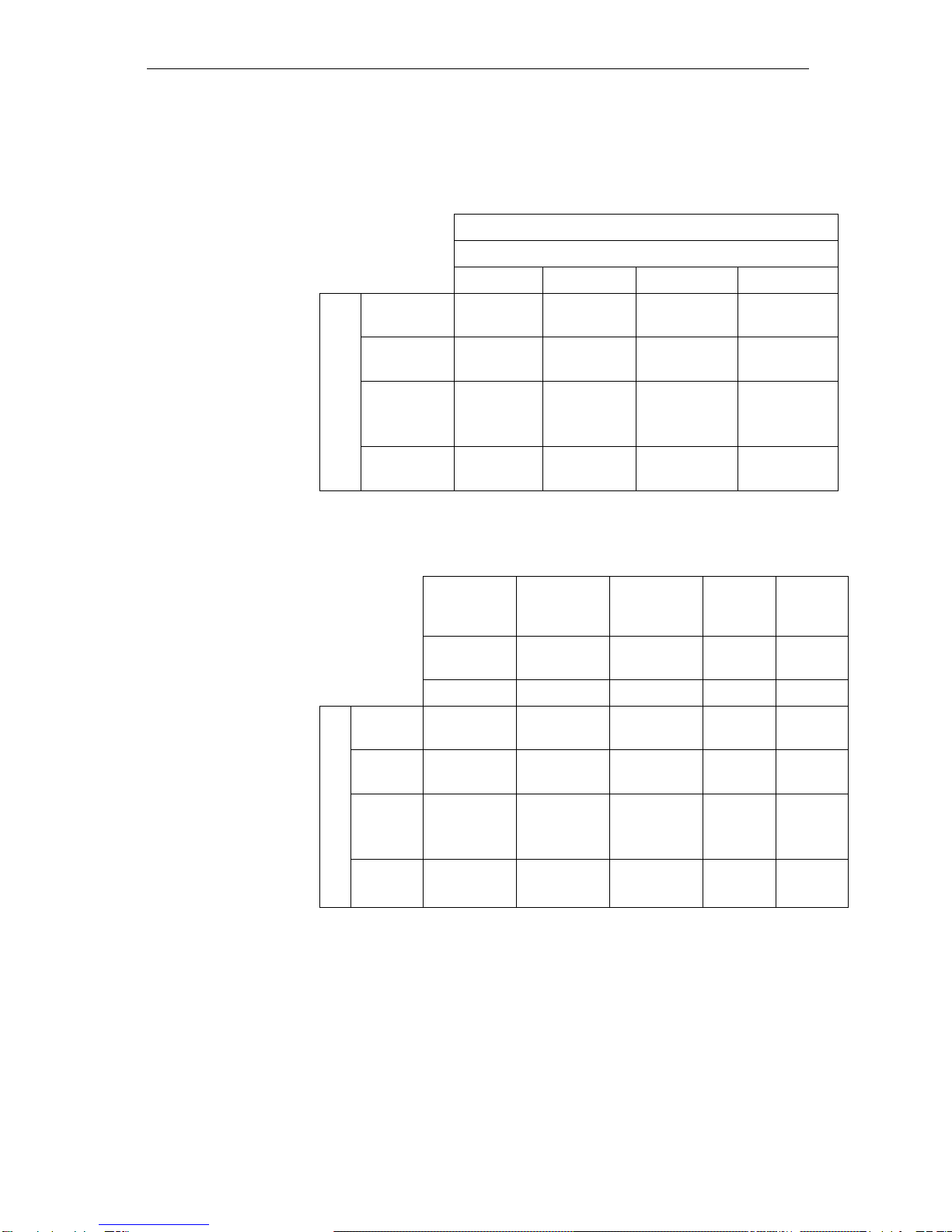

Performance specifications...............................................................7

Indicators for Testomat 2000® DUO instruments..................................8

Application instructions.....................................................................9

Installation.........................................................................................10

Operating Testomat 2000®DUO in the pressure range 0.3 to 1 bar..10

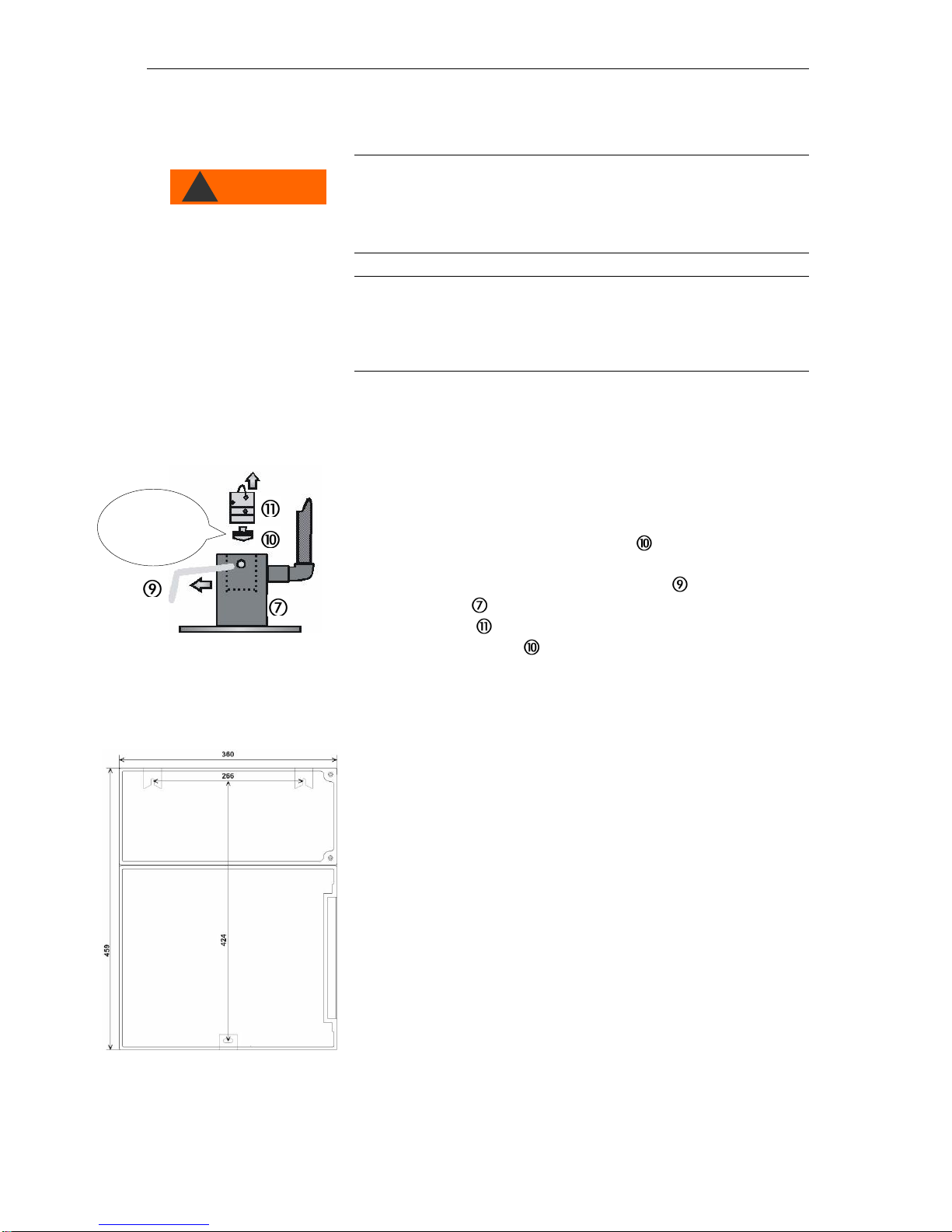

Installing Testomat 2000® DUO ..........................................................10

Connecting the water inlet and outlet .................................................11

Water inlet...........................................................................................11

Water outlet.........................................................................................11

Connecting the power supply and devices .........................................12

Block diagram Testomat 2000®DUO ................................................12

Internal design Testomat 2000®DUO.................................................13

Connecting the mains voltage.............................................................14

Connecting the plant components ......................................................15

Connecting the inputs and outputs .....................................................16

Commissioning.................................................................................17

Inserting the indicator bottle................................................................17

Extracting the indicator .......................................................................17

Opening the water inlet.......................................................................17

Instrument settings and data input......................................................18

Functions of the operating and display elements.........................18

Switching Testomat 2000® DUO on/off...............................................18

Display functions.................................................................................19

Operating elements and function keys ...............................................20

Operating system................................................................................21

Password protection and basic program.......................................22

Entering basic program data...............................................................22

Selecting the indicator and the bottle size ..........................................22

Selecting the operating mode.............................................................23

Selecting the display unit(s)................................................................24

Measuring point or parameter selection .............................................24

Entering further basic program data ..............................................25

Internal flushing...................................................................................25

External flushing .................................................................................25

Interval pause .....................................................................................26