Printed in U.S.A. 1918203/AP0305

Dealer Set-up

Instructions for

the 600 Series

Finger Wheel Rakes

These instructions provide details for unpacking and

setting up the 600 Series Finger Wheel Rakes. This

document should remain with the machine in the

manual packet. A copy of this document should be

retained by the dealer.

GENERAL INFORMATION

The 600 Series Finger Wheel Rakes are shipped in

varying stages of assembly. The following instructions

provide illustrated details of how to set up the 600 Series

Finger Wheel Rakes. Recommended setup is as follows:

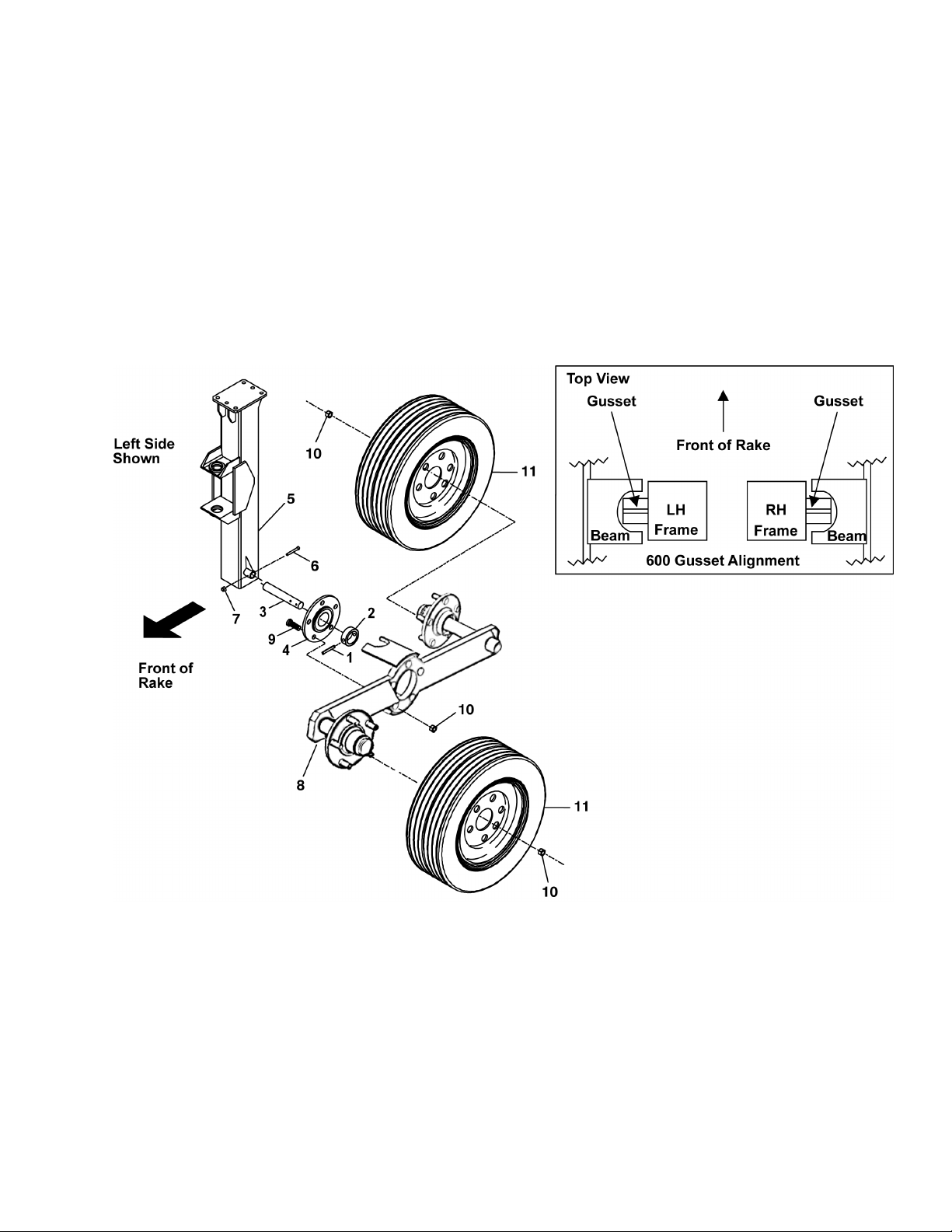

Unless otherwise noted, the standard fastening

procedure is to secure two parts with a cap screw and

lock nut. A part with a mounting slot should be secured

with a plain washer against the slotted surfaces. Lock

nuts are sometimes used to prevent two parts from

separating but still allow one part to move or rotate next

to the other. Attaching hardware, if it will require

installation in the path of material flow, should always

be installed with the head of the screw on the same side

of the part that will be in contact with the material.

SETUP

1. Implement is shipped disassembled in wooden

crates. Approximate assembly time is between

15-25 hours, depending on what options are to be

installed. The majority of the fasteners are metric.

Fig. 1

IMPORTANT: Use only metric tools for metric

fasteners.

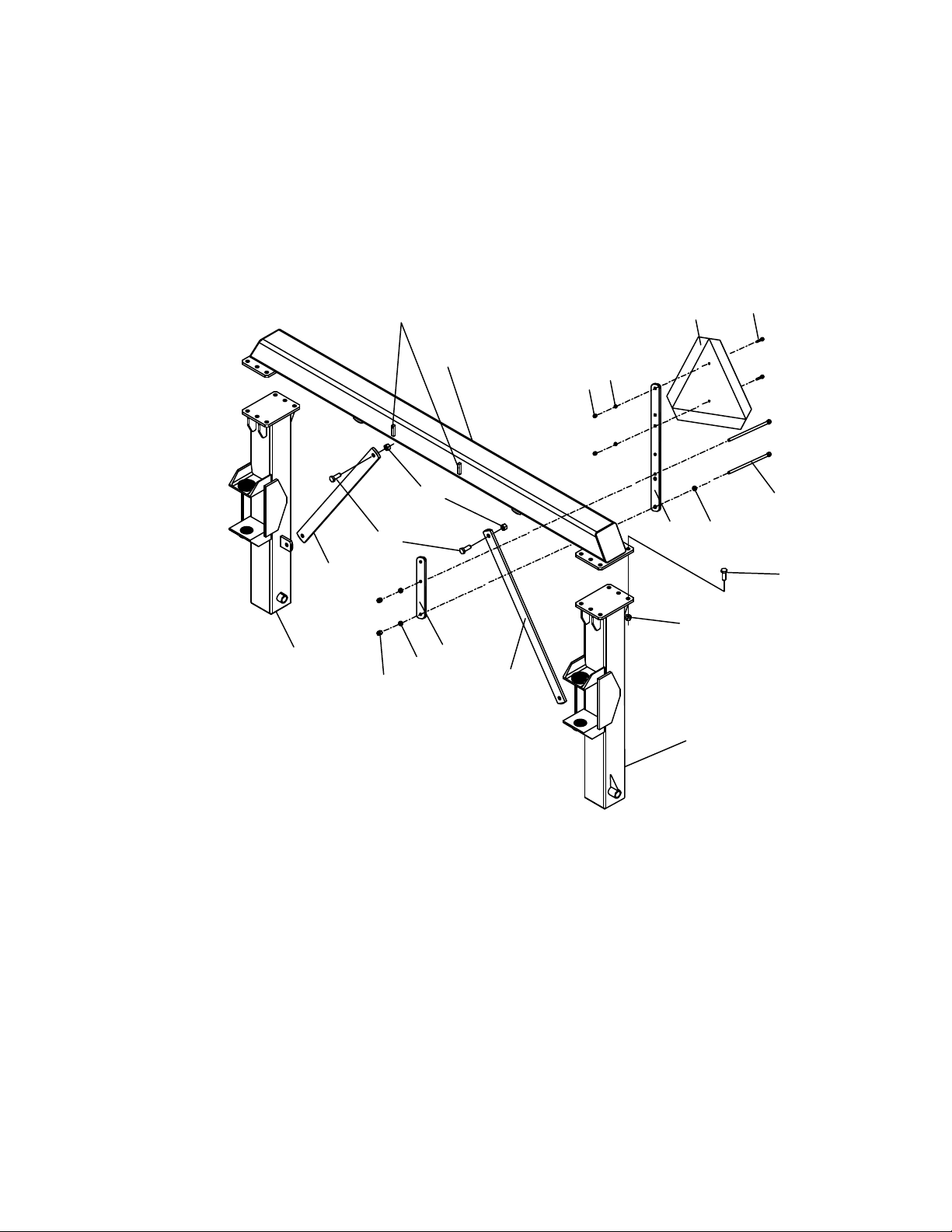

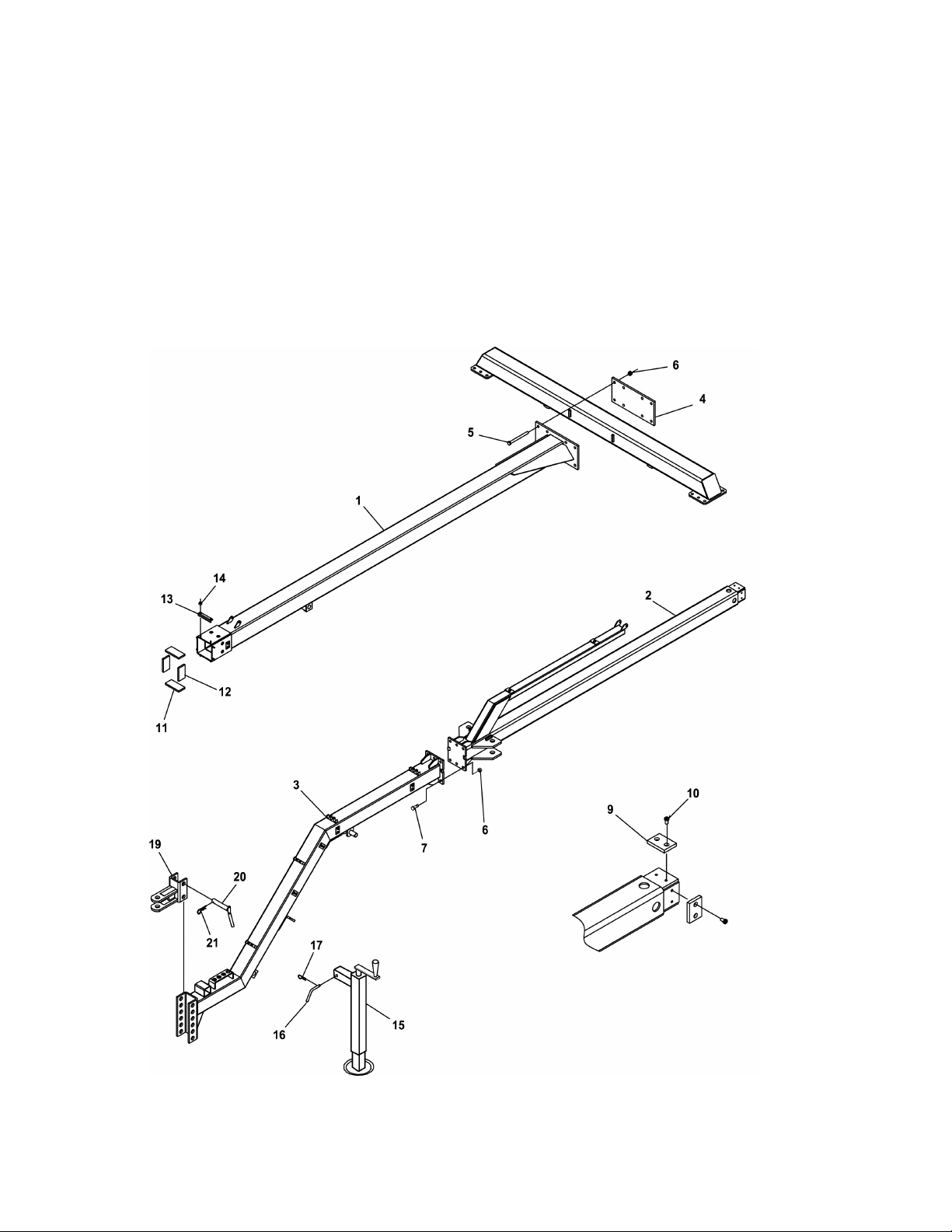

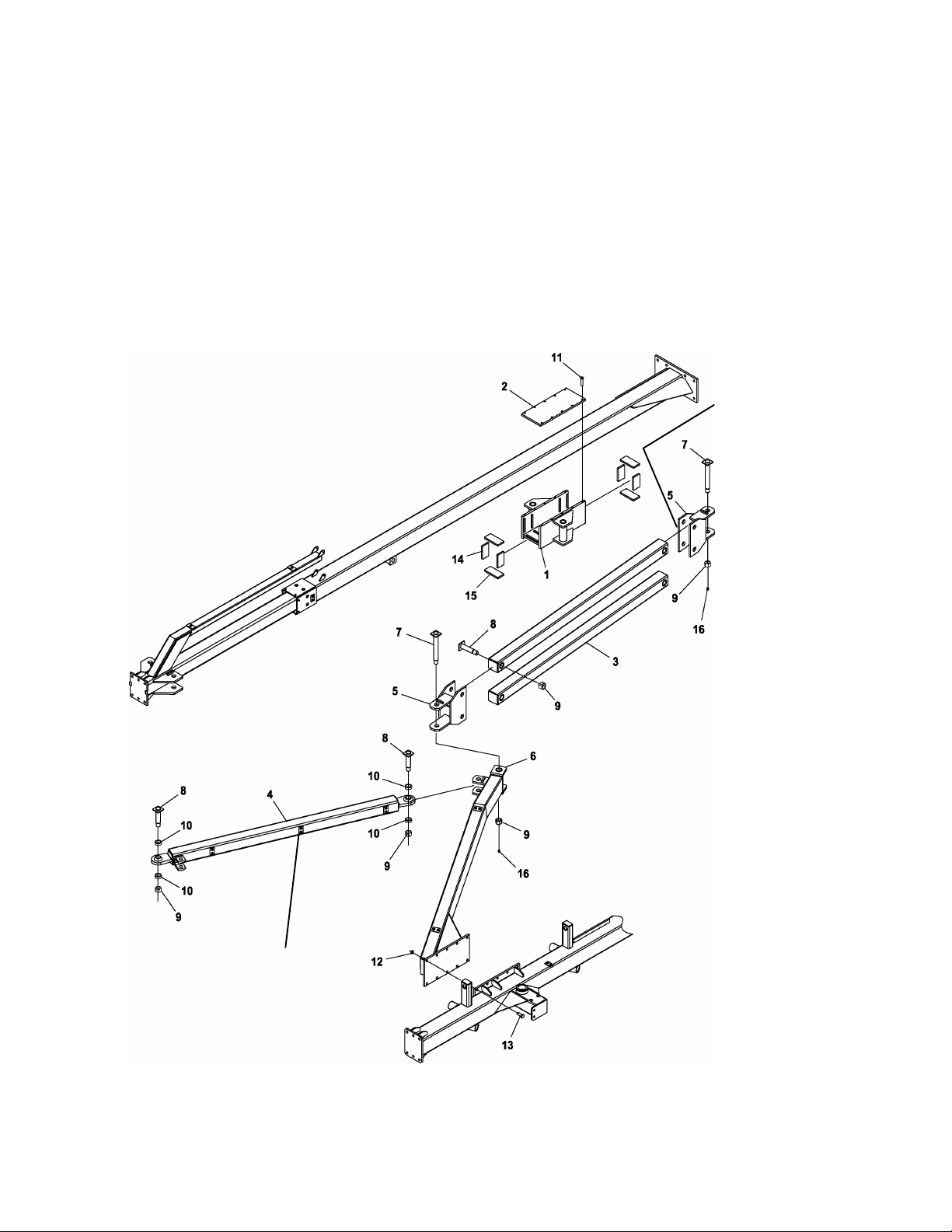

2. Select an area that has adequate space for parts

layout and machine assembly. Remove all parts

from the crate and lay them out in assembly order

according to Fig. 2.