MAN-M-O-209_07 22/11/2013 Page 8of 10

7. MAINTENANCE

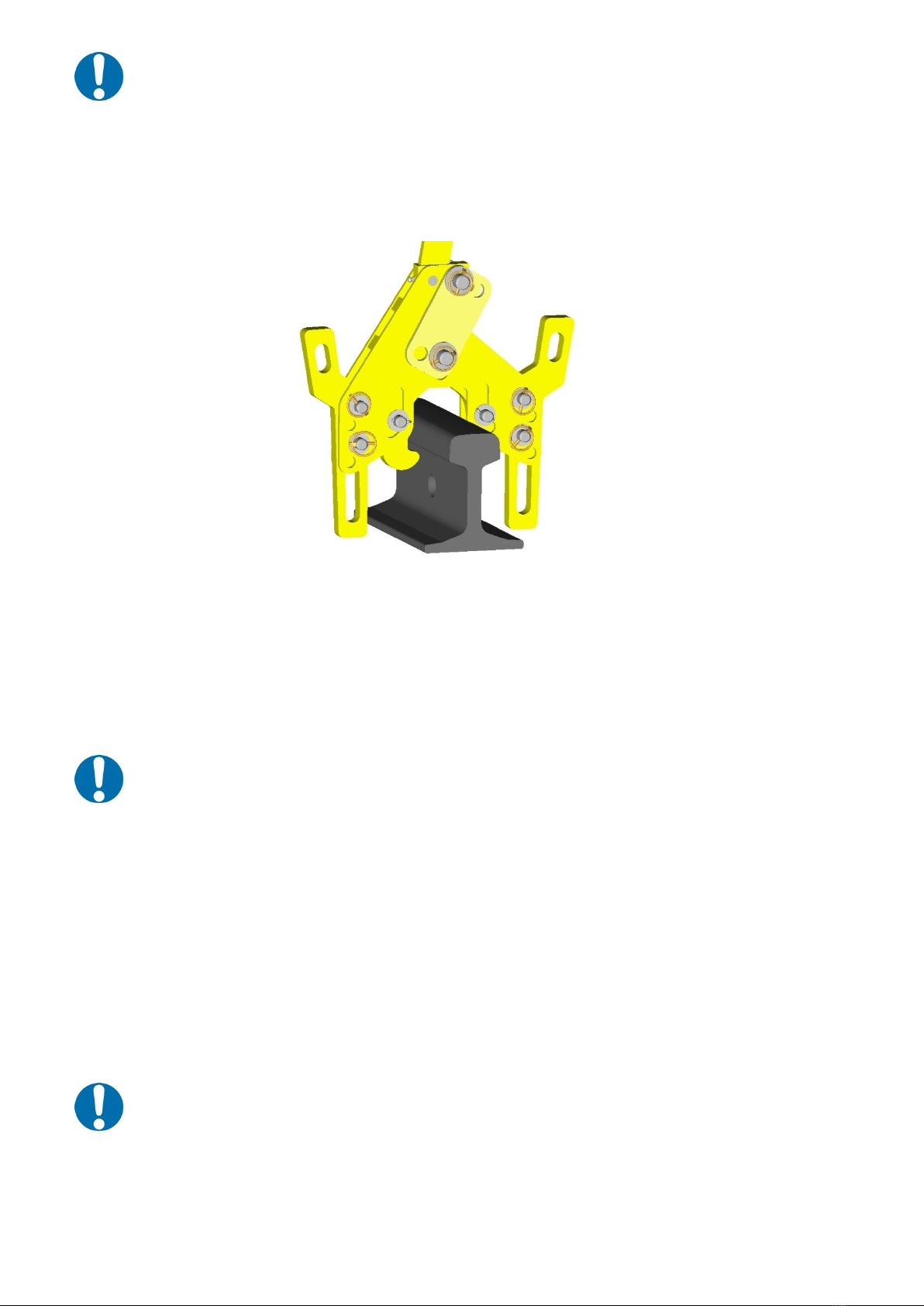

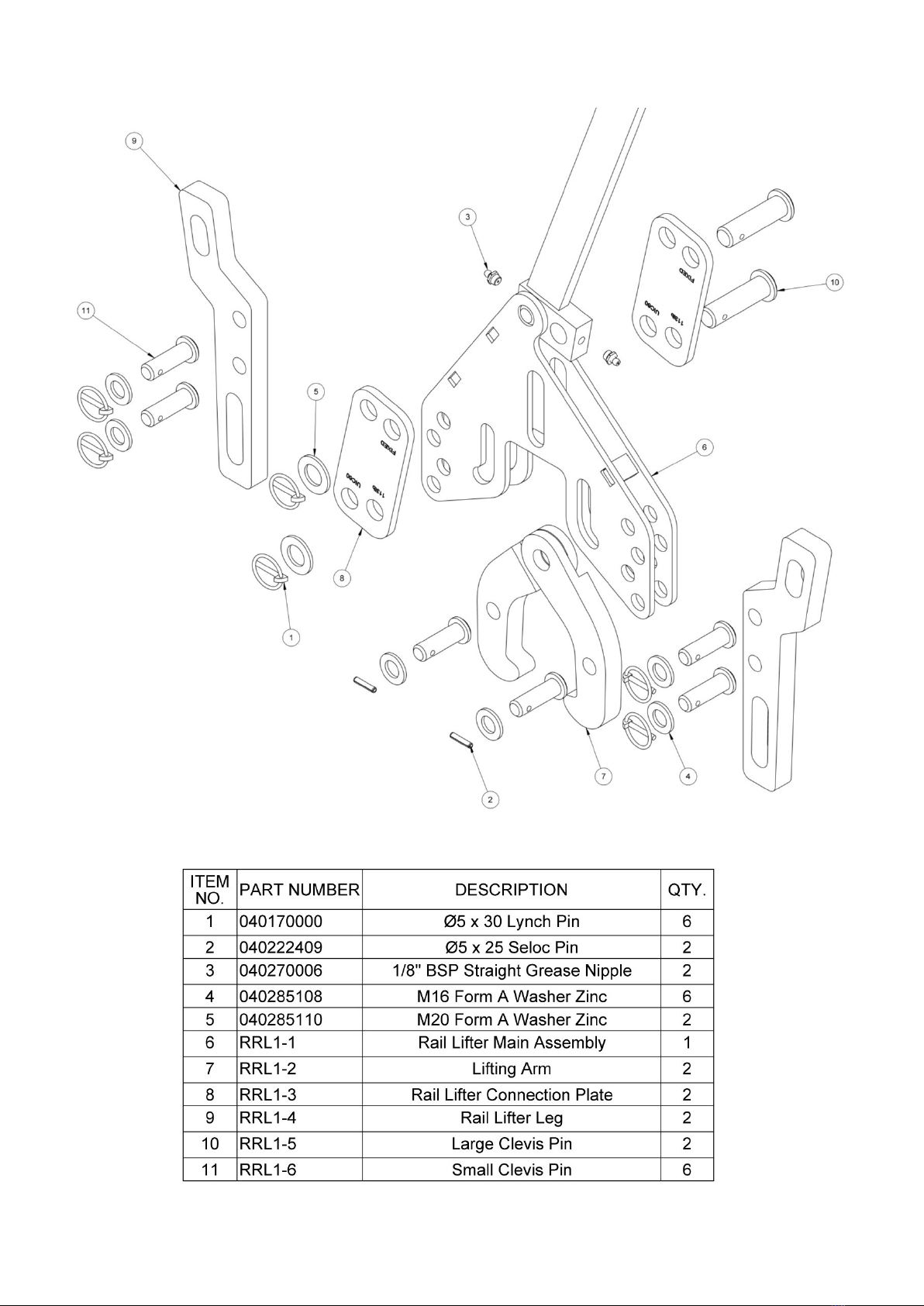

It is recommended that the following checks are carried out before using the Rail

Lifter:

a) Ensure that the Rail lifter is fitted with a valid, in date test plate. The Rail Lifter

should be tested in accordance with the current LOLER regulations. Currently

this is on a 6 monthly basis.

b) Before using the rail lifter, operate the unit and check for signs of wear in all

of the pivot pins, moving parts and the cam guide slots on the main body.

Ensure that it is working correctly and that the play in the pivot pins is not

excessive.

c) Before using the rail lifter, check the condition of the lifting arms. (item 2 on

exploded view) Ensure that the arms are not broken, cracked or excessively

worn.

d) The upper most pivot pins in the assembly must be greased on a weekly

basis using EP32 grease or equivalent. Grease nipples (item 11 on exploded

view) are fitted to the handle to facilitate the greasing of the pins. It is

permissible for the handle to have 2-3mm of vertical travel before it is

necessary to fully refurbish the rail lifter.

e) Ensure that the unit has been set correctly for the type of rail/sleepers being

used:- i.e G44 concrete / UIC60

G44 concrete / 113lb

(See section 6, for the various configurations.)

f) Ensure that all of the pivot pins are secured and held in position using their

retaining pins. These should be seloc pins and lynch pins. If any pivot or

retaining pins are missing the tool should not be used under any

circumstances.

g) Check the condition of all of the pivot pins on a weekly basis. It is permissible

for the pins to wear to a minimum diameter of Ø14mm.

h) Ensure that all of the parts are fitted and are in good condition.

i) Ensure that all moving parts are greased on a weekly basis. Use EP32

grease.

All maintenance or adjustments carried out on this lifting equipment

should only be done by suitably qualified and trained personnel.