Contents

Safety.......................................................................3

GeneralSafety...................................................3

SlopeSafety.......................................................4

ConcreteBreakerSafety....................................4

MaintenanceandStorageSafety........................4

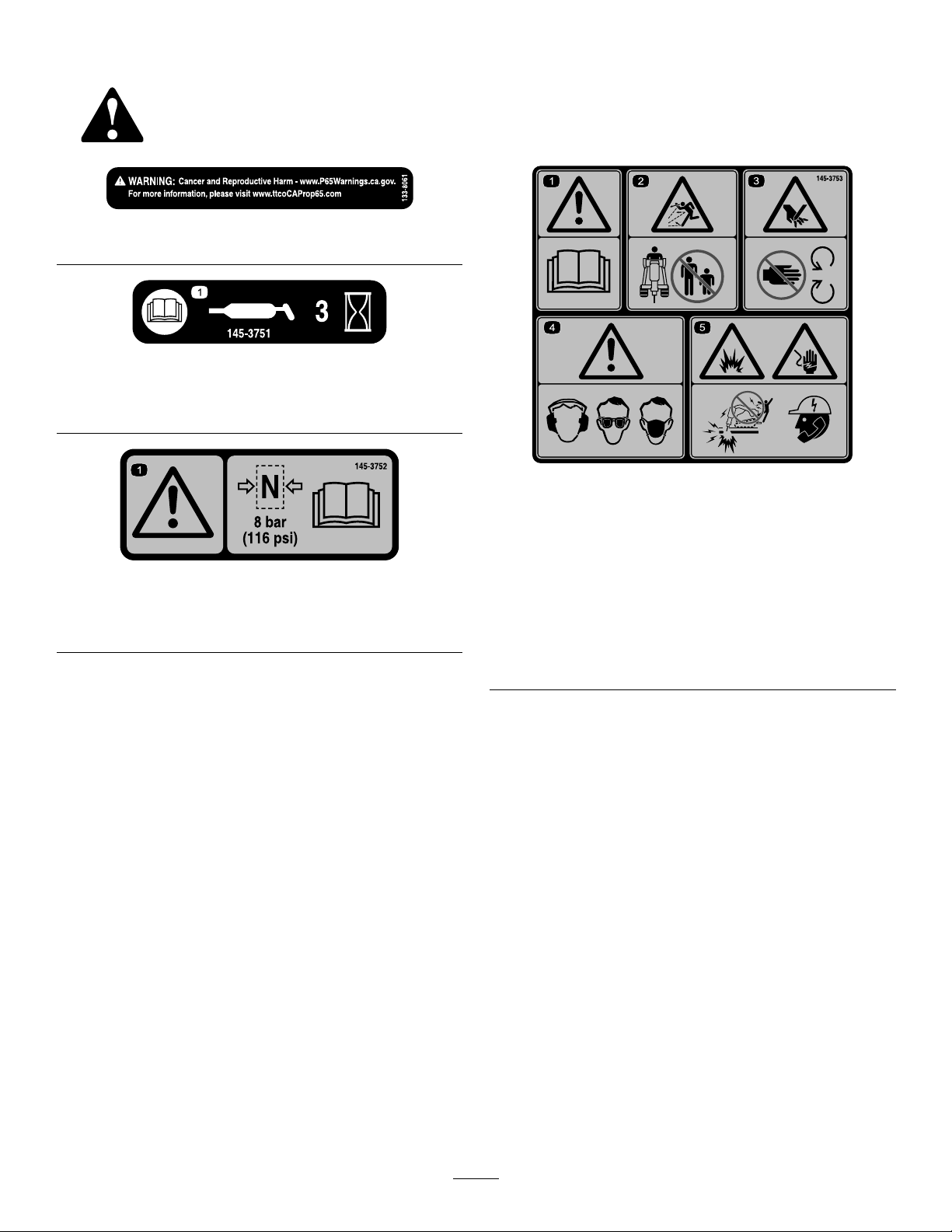

SafetyandInstructionalDecals..........................5

Setup........................................................................6

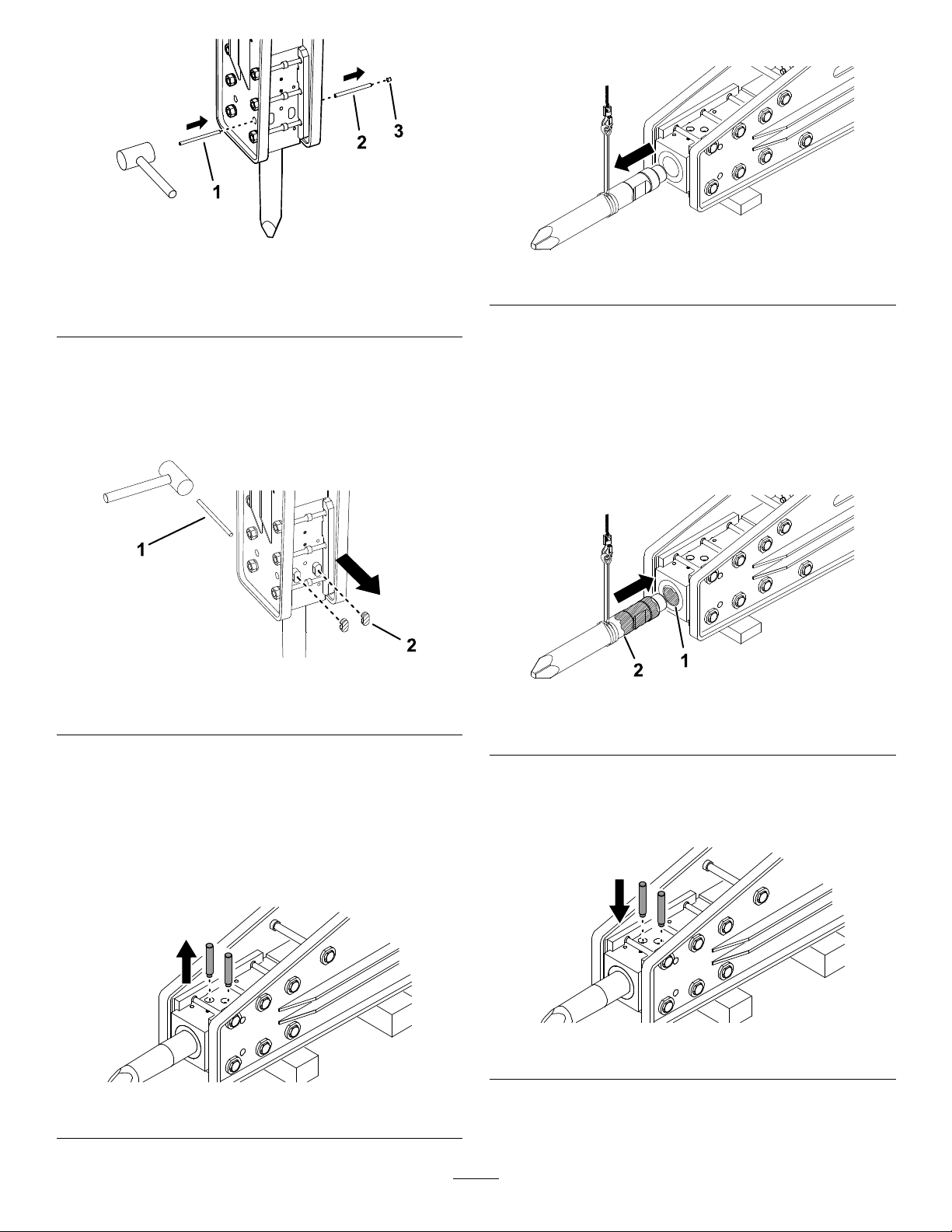

1InstallingtheBit...............................................6

ProductOverview.....................................................6

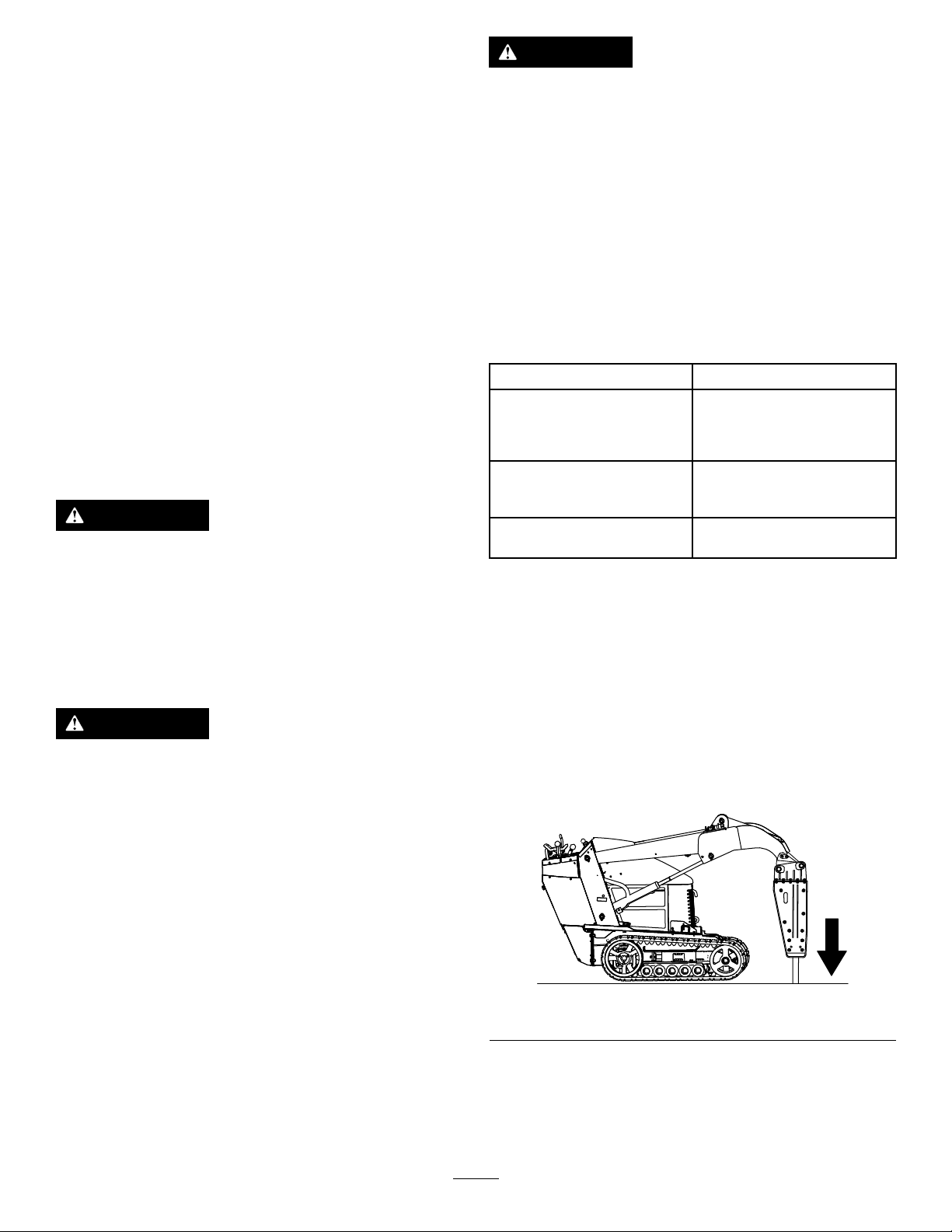

Specications....................................................6

Attachments/Accessories...................................6

Operation..................................................................7

InstallingandRemovingtheAttachment.............7

SelectingaT ool..................................................7

ReplacingtheBit................................................7

TestingtheBreaker.............................................9

BreakingMaterial.............................................10

BreakingaVerticalSurface...............................10

TransportPosition............................................10

OperatingTips..................................................11

Maintenance...........................................................12

RecommendedMaintenanceSchedule(s)...........12

GreasingtheBit................................................12

CheckingtheNitrogenCharge..........................13

CheckingtheHydraulicLines...........................13

Storage...................................................................14

StoringtheAttachment.....................................14

Troubleshooting......................................................15

Safety

DANGER

Theremaybeburiedutilitylinesinthework

area.Diggingintothemmaycauseashock

oranexplosion.

Havethepropertyorworkareamarkedfor

buriedlinesanddonotdiginmarkedareas.

Contactyourlocalmarkingserviceorutility

companytohavethepropertymarked(for

example,intheUS,call811orinAustralia,

call1100forthenationwidemarkingservice).

GeneralSafety

Alwaysfollowallsafetyinstructionstoavoidserious

injuryordeath.

•Donottransportanattachmentwiththearms

raised.Alwaystransporttheattachmentcloseto

theground;refertoTransportPosition(page10).

•Havethepropertyorworkareamarkedforburied

linesandotherobjects,anddonotdiginmarked

areas.

•ReadandunderstandthecontentofthisOperator’s

Manualbeforestartingtheengine.

•Useyourfullattentionwhileoperatingthe

machine.Donotengageinanyactivitythat

causesdistractions;otherwise,injuryorproperty

damagemayoccur.

•Neverallowchildrenoruntrainedpeopleto

operatethemachine.

•Keepyourhandsandfeetawayfromthemoving

componentsandattachments.

•Donotoperatethemachinewithouttheguards

andothersafetyprotectivedevicesinplaceand

workingonthemachine.

•Keepbystandersandpetsawayfromthemachine.

•Stopthemachine,shutofftheengine,andremove

thekeybeforeservicing,fueling,orunclogging

themachine.

Improperlyusingormaintainingthismachinecan

resultininjury.Toreducethepotentialforinjury,

complywiththesesafetyinstructionsandalways

payattentiontothesafety-alertsymbol,which

meansCaution,Warning,orDanger—personalsafety

instruction.Failuretocomplywiththeseinstructions

mayresultinpersonalinjuryordeath.

3