3 –COMMISSIONING - USE

•Review the electrical and water installation. Be sure to follow the assembly instructions written above

correctly. If there is no deficiency or error, you can start the commissioning process.

•Open the water inlet and water outlet valves, turn off the bypass valve. Make sure there are no water

leaks in the valves and the chamber.

•Make sure that phase, neutral and ground wires are properly connected. Remember, the device will

work with the pump and shut down with the pump. Open the residual current relay/fuse. Check the

supply terminals with the control pen or gauge.

•Turn on the device using the on / off switch at the bottom of the device. The control screen on the

front of the device will be energized. There will be a closed mode screen on the control screen.

•The generator will work at the factory settings. If you want to change these settings, you can make

the necessary changes with the help of the user guide.

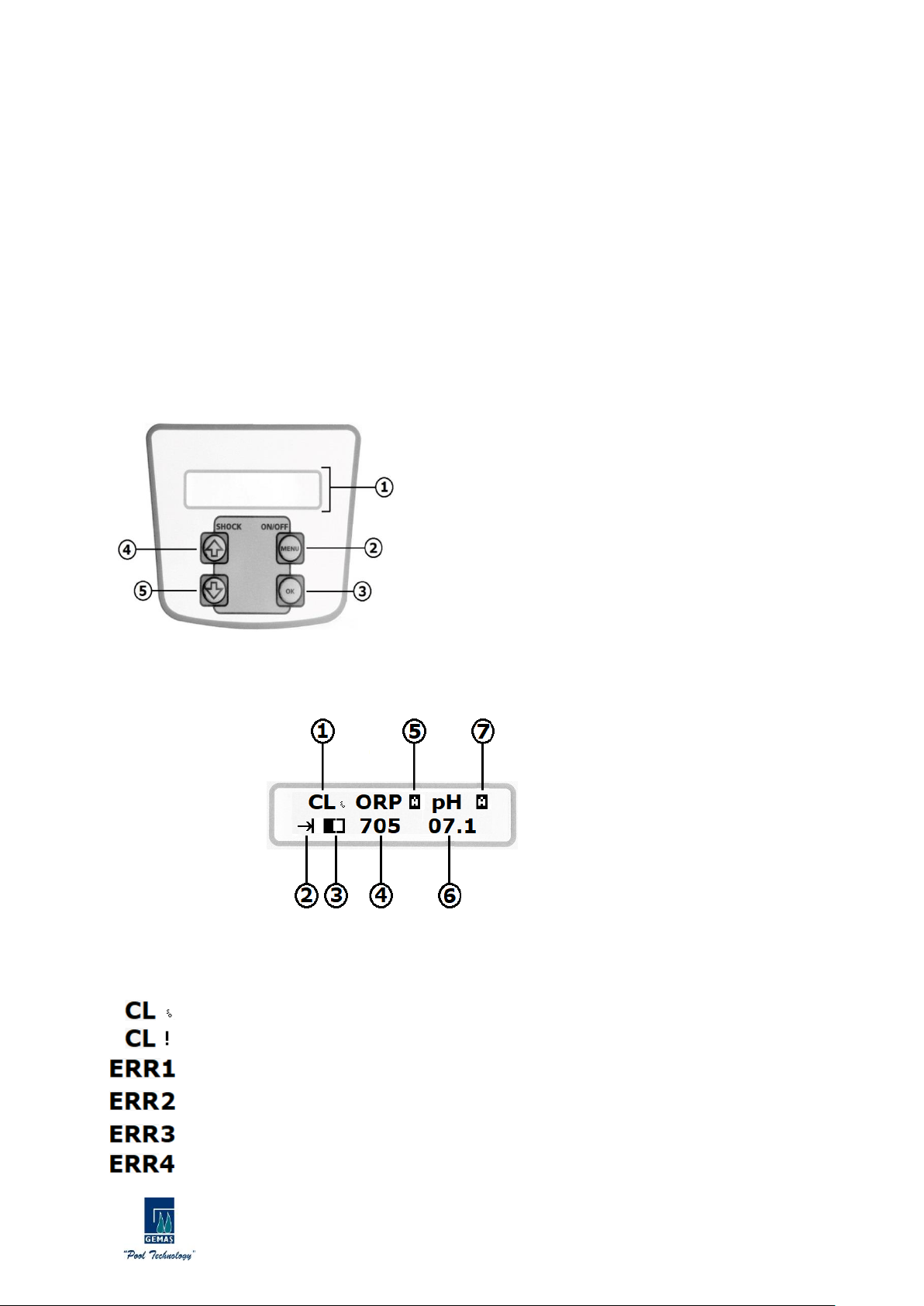

3.1. Control Panel and Settings

1 - 2x16 LCD screen; information and warnings about the

device are displayed.

2 - The device performs the functions of ON / OFF (switching on

/ off), entering the setting menu (the device is turned off,

pressed for 3 seconds when it is OFF), and exit the pages and

parameters in the setting menu.

3 - Selection of the pages and parameters in the setting menu,

performs the functions of confirming and saving the set

parameters.

4 - In the settings menu, it performs the functions of passing to

the next page or parameter and increasing the parameter

values.

5 - In the settings menu, it performs the functions of switching to a sub-page or parameter and decreasing

parameter values.

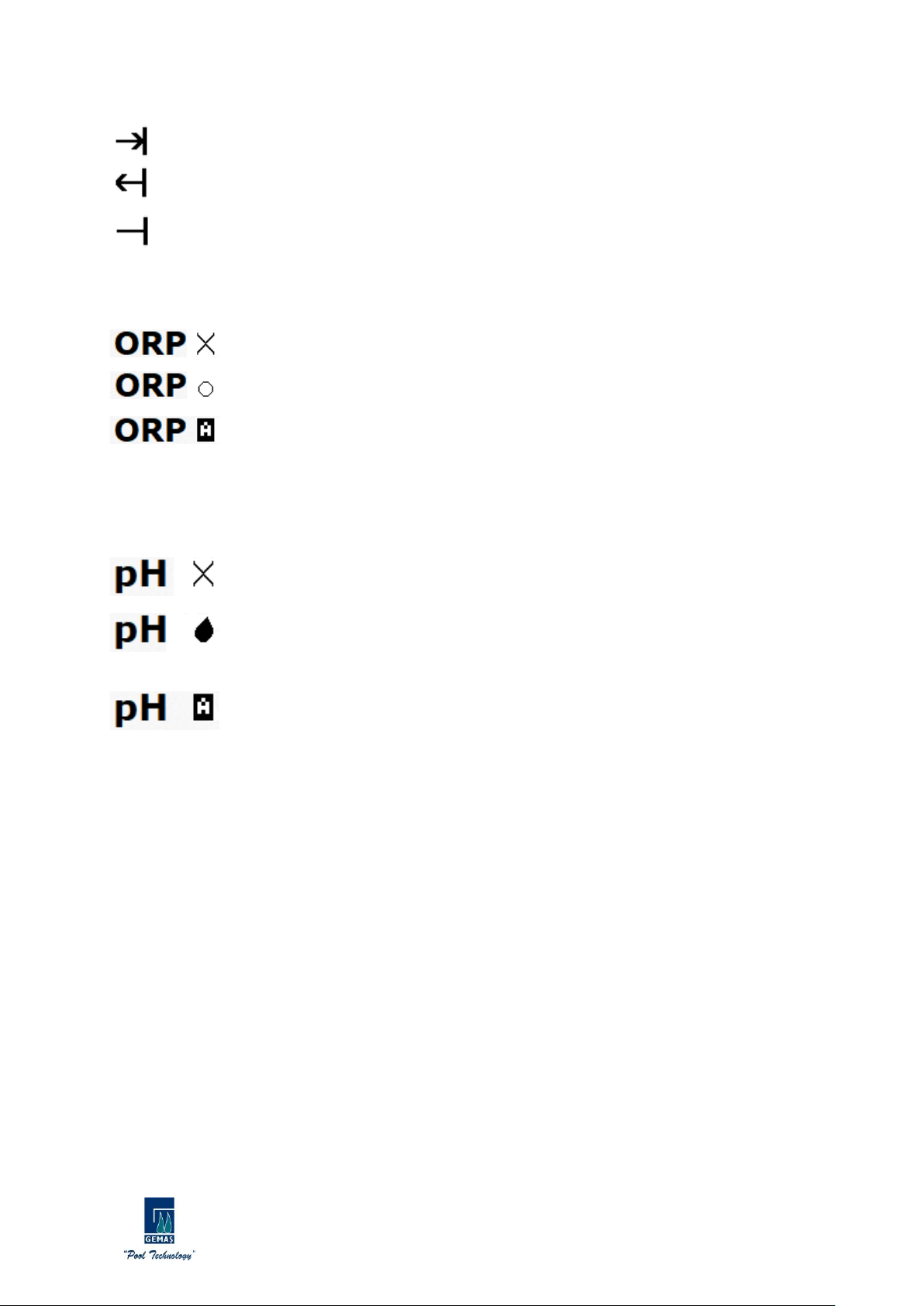

3.1.1. Control Panel Operation Screen Icons and Values

1 - Failure and Warning Part Related to Cl Production: This section shows errors and warnings affecting Cl

production. By pressing the OK button once, the instantaneous current value drawn during production is

displayed. Detailed information about faults is described in Fault Codes and Suggested Solutions.

It states that Cl is produced and the salt level is ideal.

It indicates that Cl is produced, but the level of salt is incomplete.

Indicates a malfunction with the electrode cable.

Indicates lime between the electrode plates.

Indicates a short circuit between the electrode cable or electrode plates.

This means that there is a problem with the electronic circuit board, the seller/manufacturer must

be contacted.