GEMINI CONTROLS LLC

Phone (262) 377-8585

P.O. Box 380 W61 N14280 Taunton Ave. FAX (262) 377-4920

Cedarburg, WI 53012 Email: sales@geminicontrols.com

www.geminicontrols.com

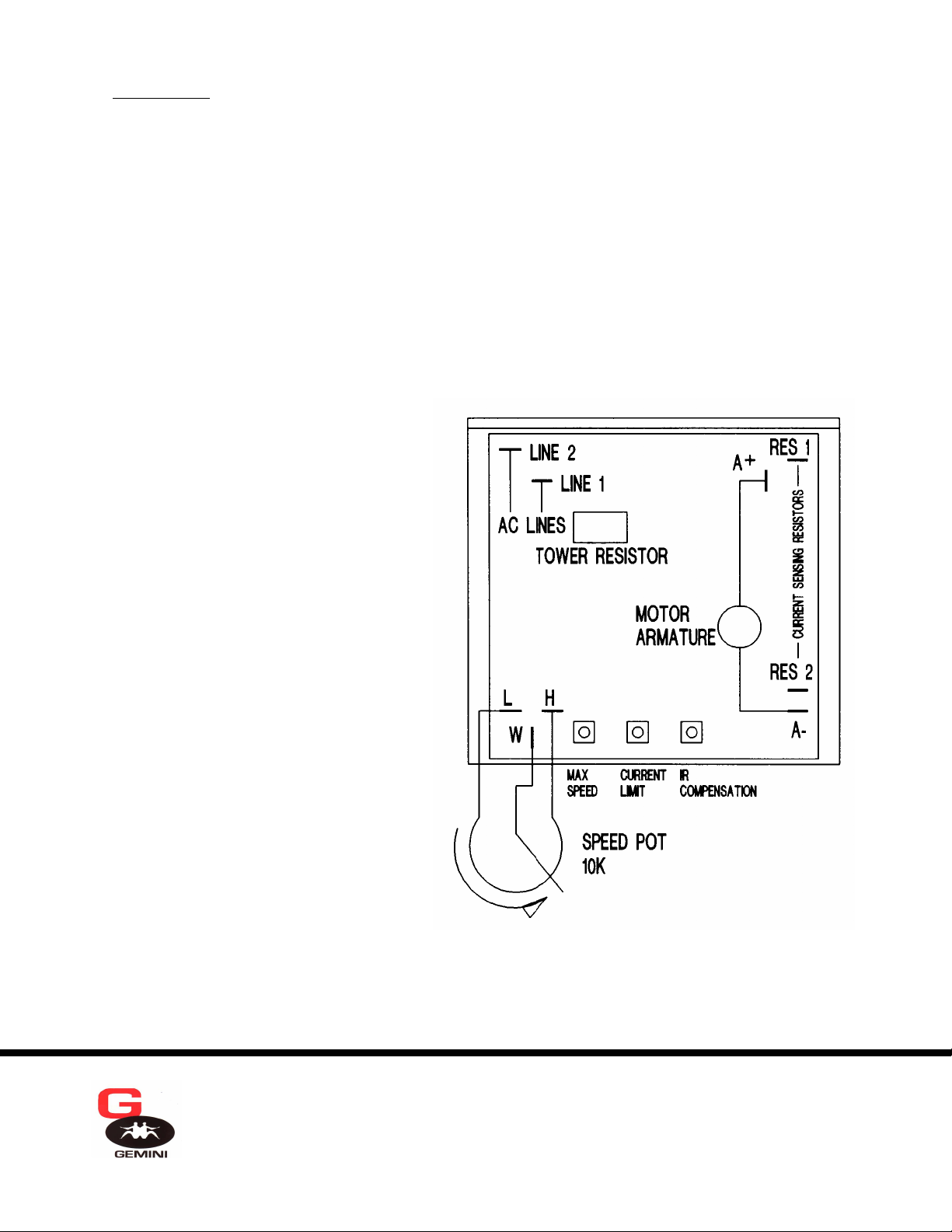

3. Control Wiring - Connect a 10K, 1/4 watt speed potentiometer to the “L”, “W”, and “H” terminals, with the wiper

connected to the “W” terminal, and the CCW end wired to the “L” terminal. If an external 0-10VDC speed reference

signal is used, first set-up and adjust the system with a 10K potentiometer as a speed reference. Connect the isolated,

external source only after satisfactory operation with a potentiometer, as any problem may then be directed toward

interfacing. The frequency of a pulse width modulated, isolated, input signal must exceed 50Hz, otherwise damage may

result. Wire the common to the “L” terminal and the positive voltage to the “W” terminal.

If shielded wire is used, ground the shield at the potentiometer. Never connect the shield at both ends. Do not run control

wiring in conduit with high voltage (115V or greater) wiring.

ADJUSTMENTS AND START-UP

1. Turn the “IRC” and “M.S.” (maximum speed) potentiometers, located on the board, and speed adjustment potentiometer

to their full counterclockwise position. Set the “C.L.” (current limit) pot. to mid-range.

2. Apply power and rotate the speed potentiometer

slightly clockwise. Observe the direction of rotation.

If incorrect, turn off the power and reverse the motor

armature connections.

3. Rotate the speed potentiometer to the extreme

clockwise position, and adjust the “M.S.”

potentiometer for the desired maximum speed, or for

rated motor voltage as measured with a DC meter at

the armature connection.

4. Adjust the “IRC” potentiometer clockwise until

the motor runs smoothly under different load

conditions. If the motor starts to surge, turn the

“IRC” pot. counterclockwise until surging stops.

Uncontrolled surging may blow the fuse or damage

the control.

5. The “CURR LIMIT” potentiometer can now be

adjusted so that the motor will not stall under

maximum load. Clockwise adjustment increases

the current limit, and the torque available from the

motor. If additional torque is required for

acceleration, increase the current limit setting.

The system is now ready for operation.