Horizontal: ±15°

1/2" Min.

.8 Min. #18 AWG, 24" L., Polymeric

900

Approx. 3/4"

.9 Min. .85 Min.

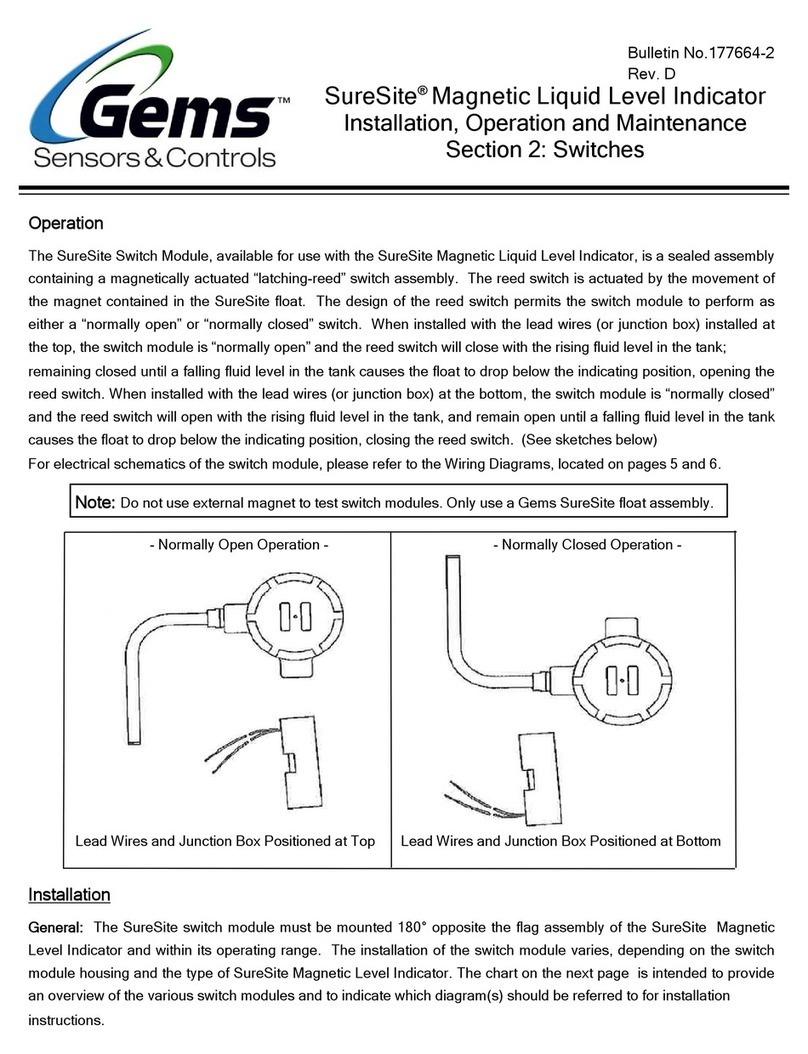

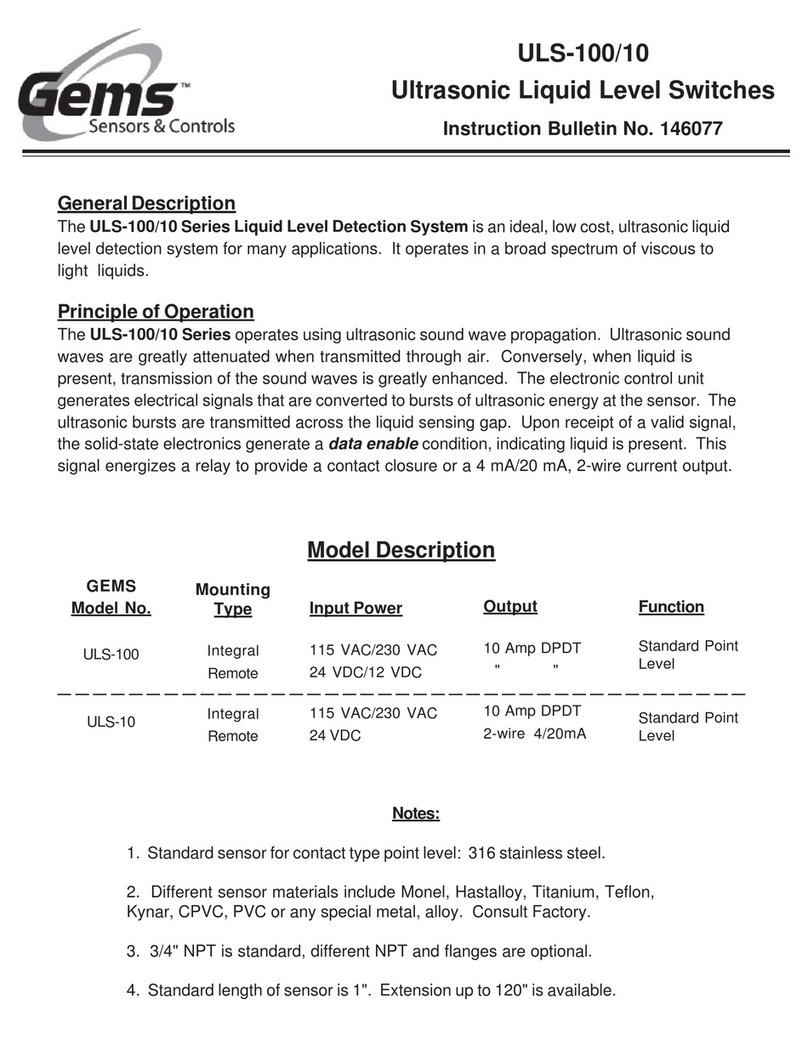

Maintenance . . .

An occasional cleaning when excessive contamination is present in the liquid is all that is

normally required. To clean unit: Compress split end of cam pivot pin, remove pin and

disassemble unit as shown below. Wipe parts clean with hydrocarbon solvent and

reassemble unit. Lock cam pivot pin by spreading split end slightly with screwdriver.

P/N 72950

Rev.P

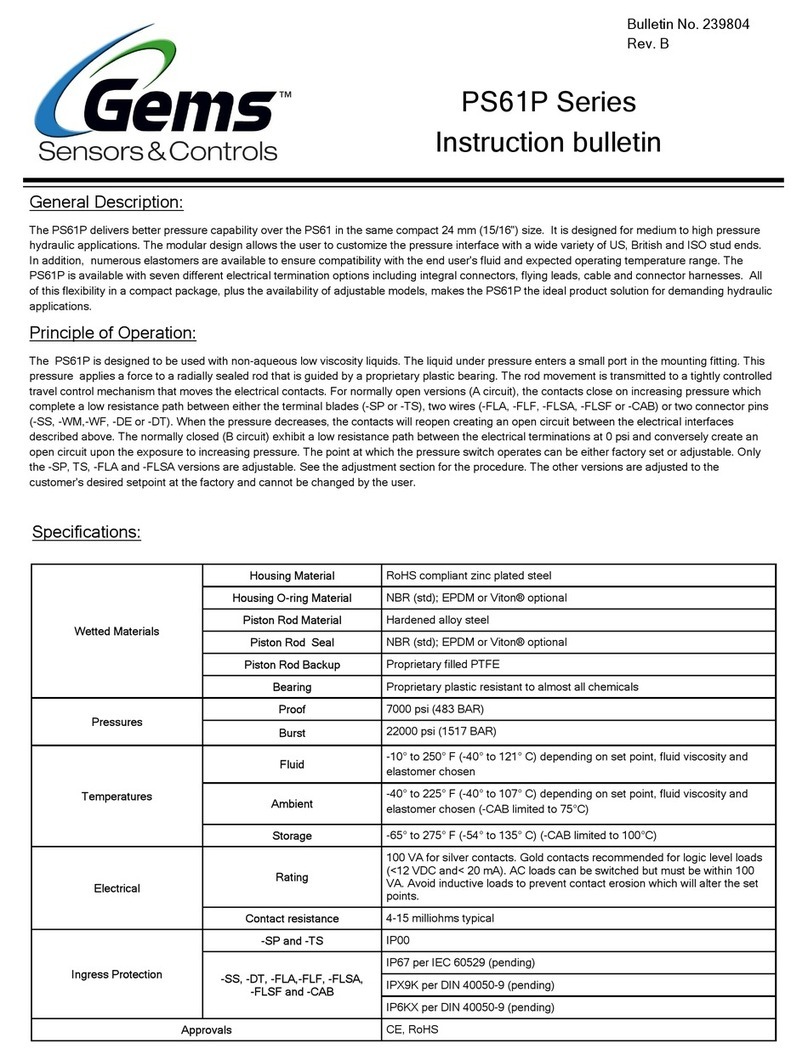

Units are side-mounted in the tank at the point of high, low or intermediate

level sensing. Ideal for tanks with "hard-to-get-at" tops or bottoms. Float

and cam action is positive. Standard versions are U.L. Recognized - File

No. E45168. Explosion-proof units are approved for Class I, Division I,

Group D hazardous areas.

CSA Listed

Standard

Versions Switch*

Explosion-Proof Versions

30288

30290

48068

48069

FM Approved

----

55690

----

----

SPDT, 20 VA

SPDT, 20 VA

SPST, 100 VA, N.O.**

SPST, 100 VA, N.C.**

LS-2050's

52100

116971

116972

LS-52100's

----

55690

----

----

121753

----

----

121753

----

----

SPDT, 20 VA

SPST, 100 VA, N.O.**

SPST, 100 VA, N.C.**

*See "Electrical Data" on next page for more information

**100 VA switches are not UL recognized or CSA listed

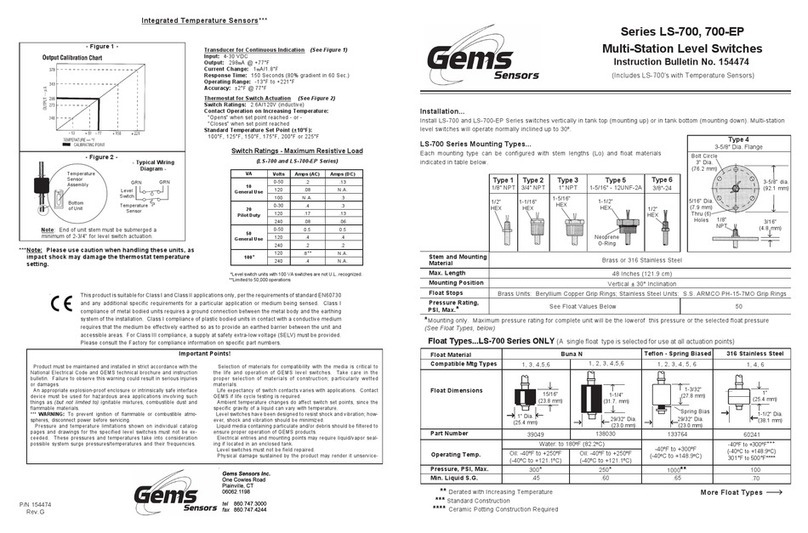

Stem & Mtg Material

Float Material

LS-2050 LS-52100

Brass

Buna N

316 SS,

Beryllium Copper,

Teflon,

Ceramic

Other Wetted

Materials

316 SS

316 SS

SS,

Teflon,

Ceramic

316 SS

304 SS

Teflon,

Ceramic

150

Water: To +180°F

Oil: -40° to +250°F -40°F to +300°F

PSIG, Max. @ 70°F

Mounting Attitude

Switch Differential

(In Liquid)

Liquid Specific Gravity

Lead Wires

Operating Temp °F

500

Housing and

Stem Assembly

Permanent

Magnet

Spring Shuttle Float and Cam

Assembly

Cam Pivot Pin

Electrical Connection . . .

Electrical connection is provided by wire leads with 1/2" NPT or junction box with 1/2"

NPT.

Typical Wiring Diagrams . . .

Specifications . . .

LS-2050/LS-52100 Series

Side-Mounted Level Switches

Instruction Bulletin No. 72950

Product must be maintained and installed in strict accordance

with the National Electrical Code and GEMS technical brochure

and instruction bulletin. Failure to observe this warning could re-

sult in serious injuries or damages.

An appropriate explosion-proof enclosure or intrinsically

safe interface device must be used for hazardous area appli-

cations involving such things as (but not limited to) ignitable

mixtures, combustible dust and flammable materials.

*** Warning: To prevent ignition of flammable or combus-

tible atmospheres, disconnect power before servicing.

Pressure and temperature limitations shown on individual

catalog pages and drawings for the specified level switches

must not be exceeded. These pressures and temperatures

take into consideration possible system surge pressures/tem-

peratures and their frequencies.

Selection of materials for compatibility with the media is

critical to the life and operation of GEMS level switches. Take

care in the proper selection of materials of construction; par-

ticularly wetted materials.

Important Points!

Lifeexpectancyofswitch contactsvaries withapplications.

Contact GEMS if life cycle testing is required.

Ambient temperature changes do affect switch set

points, since the specific gravity of a liquid can vary

with temperature.

Level switches have been designed to resist shock

and vibration; however, shock and vibration should be

minimized.

Liquid media containing particulate and/or debris

should be filtered to ensure proper operation of GEMS

products.

Electrical entries and mounting points may require liq-

uid/vapor sealing if located in an enclosed tank.

Level switches must not be field repaired.

Physical damage sustained by the product may ren-

der it unserviceable.