Installation (Contd.)

5. Connect VDC (±10%) power to red lead; return (-) to

black lead. Caution: Do not connect output to VDC

power without a load.

6. Output Configuration: See Wiring Diagrams.

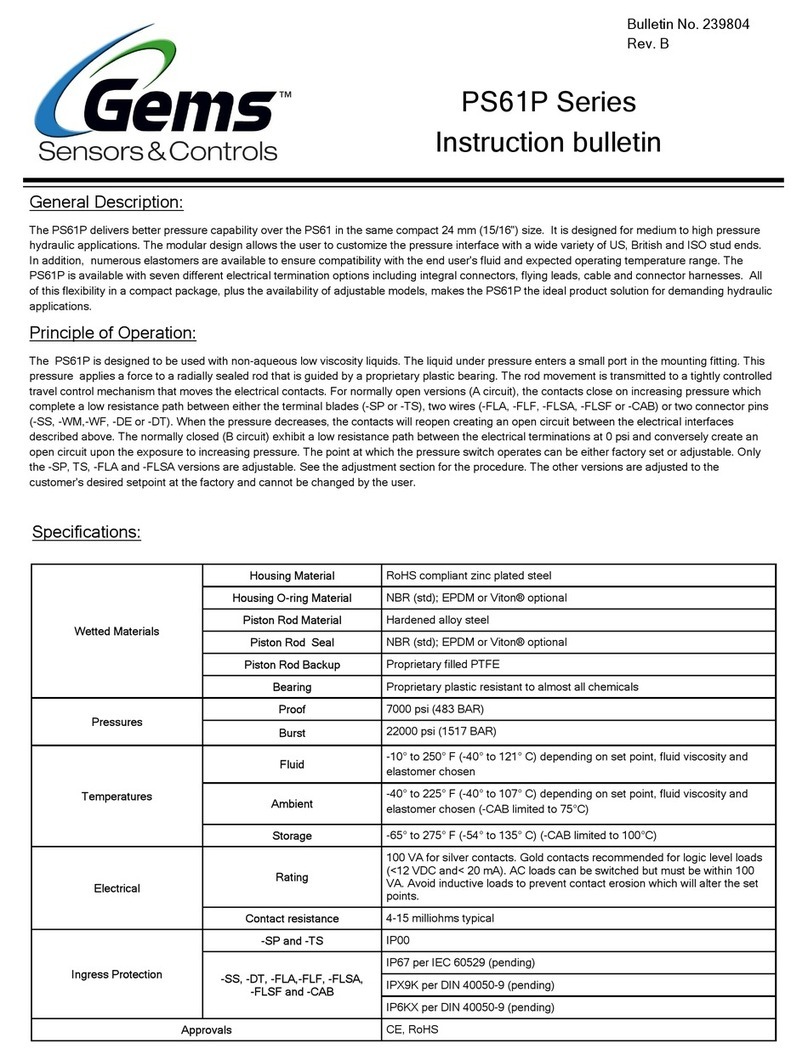

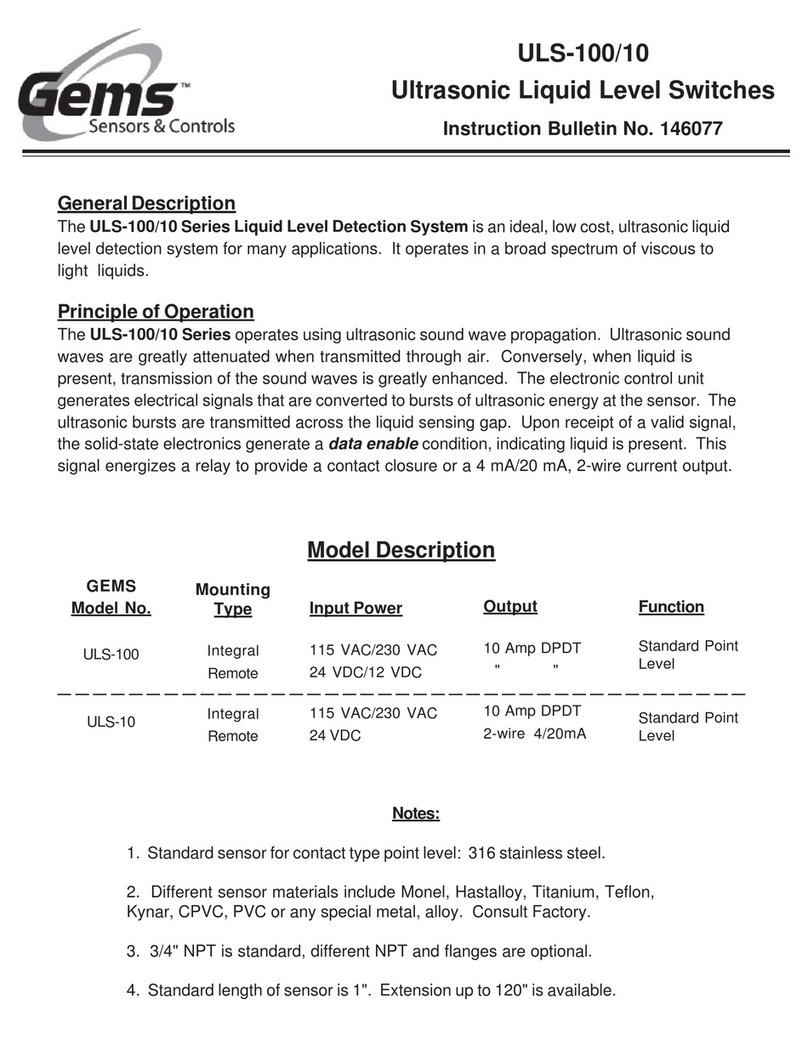

Typical Wiring Diagrams

Black Switch

Red

White

Input

Power

+ VDC

Load

+ VDC

Switch

Red

White

Input Power

+ VDC

Black

*

**L

O

A

D

Switch

Input

Power

+ VDC

Load

+ VDC

Red

White

**

Black

Notes

*TTL/CMOS Output: For levels greater

than 5 volts, a 10K pull-up resistor is

required at the output.

** Maximum Load = 40mA @30 VDC

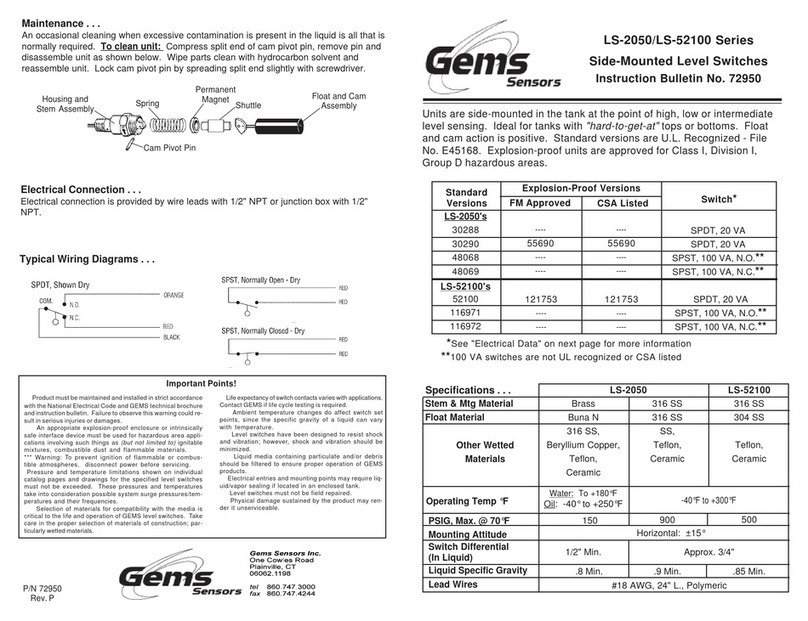

Maintenance

Sensor may require a periodic cleaning of prism surface.

Chlorinated hydrocarbons must not be used for cleaning.

A mild detergent may be used to clean prism surface.

Return Policy

Returns are accepted on stock items up to 30 days from date of

order. You must contact our Returns Department for a Return

Authorization (RA) number. Return the goods - freight prepaid - in

the original container and include original packing slip.

C. O. D. returns are not accepted. Gems reserves the right to

apply restocking charges.

Tel: 860-793-4357

Fax: 860-793-4563

Gems Sensors Inc.

One Cowles Road

Plainville, CT 06062-1198

Toll-Free: 1-800-378-1600

• Gems products must be maintained and installed in strict accordance with the National Electrical

Code and the applicable Gems Product Instruction Bulletin that covers installation, operation and

proper maintenance. Failure to observe this information may result in serious injury or damages.

•For hazardous area applications involving such things as, but not limited to, ignitable mixtures,

combustible dust and flammable materials, use an appropriate explosion proof enclosure or

intrinsically safe interface device.

•Please adhere to the pressure and temperature limitations shown throughout this catalog for our

levelandflowsensors.Theselimitationsmustnotbeexceeded.Thesepressuresandtemperatures

take into consideration possible system surge pressures, temperatures and their frequencies.

•Selection of materials for compatibility with the media is critical to the life and operation of Gems

products. Take care in the proper selection of materials of construction, testing is required.

•Stainless steel is generally regarded as safe by NSF and FDA.

•NSF-approved sensors are made of materials approved for potable water applications according

to Standard 61.

•Life expectancy of switch contacts varies with application. Contact Gems if life cycle testing is

required.

•Ambient temperature changes do affect switch set points, since the gravity of a liquid can vary with

temperature.

•Oursensorshavebeendesigned to resist shock and vibration. However, shock and vibration should

be minimized.

•Filterliquidmediacontainingparticulateand/ordebristoensuretheproperoperationofourproducts.

•Electrical entries and mounting points in an enclosed tank may require liquid/vaporsealing.

•Our sensors must not be field-repaired.

Important Points:

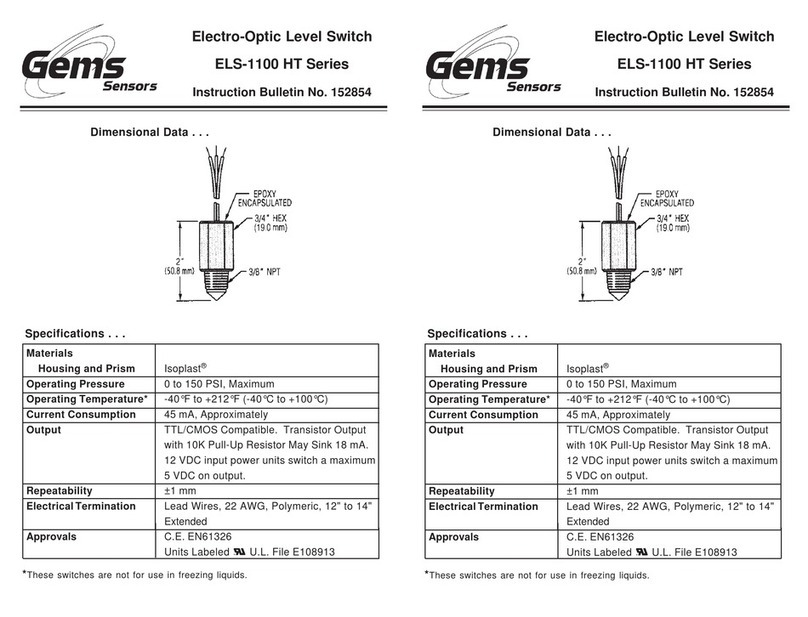

Dimensions

1/4” NPT Mounting 1/4” NPT Mounting

with 3/8” Conduit 1/2” Straight Thread

Mounting with O-Ring

M12x1 Straight Thread

Mounting with O-Ring “Fish” Pull Ring

Flange Mounting

Threaded Holes Not Required

Electrical Termination: Lead Wires, 22 AWG, PVC Jacketed, 12” to 14” Extended

Electrical Termination: Lead Wires, 22 AWG, PVC Jacketed, 12” to 14” Extended 25’ Cable, 22 AWG, PVC Jacketed

Lead

Wires

2-5/32”

(54.7 mm) Epoxy

Encapsulated

5/8” HEX

(15.9 mm)

1/4”

NPT

2-5/32”

(54.7 mm)

5/8” HEX

(15.9 mm)

1/4”

NPT 3/8” NPT

Mounting

2-5/32”

(54.7 mm)

5/8” HEX

(15.9 mm)

Viton

O-Ring

1/2” - 20

UNF .47”

Ref.

.47”

Ref.

2-5/32”

(54.7 mm)

5/8” HEX

(15.9 mm)

Viton

O-Ring

M12 x 1 ←

→2-5/8” Ref.

(66.7 mm)

Removable PVC

Fish Pull Ring 5/8” HEX

(15.9 mm)

Cable

2.16” Ref.

1/4” Max. Wall Thickness

1/8” Thick

Viton Gasket 11/16”-16 Thd. REF

←

→

Mating O-Ring Gland Design

1/2" Straight Thread M12 X 1 Straight Thread

SAE #5 TUBE FITTING 12° .555

.550 .108

.093

1/2-20 UNF 2B

.020

[.50mm]

∅ .570 ± .002

[14.5 ± .05 mm]

M12 X 1 - 8G

45°

.150

[3.80mm]

∅(AT TOP)