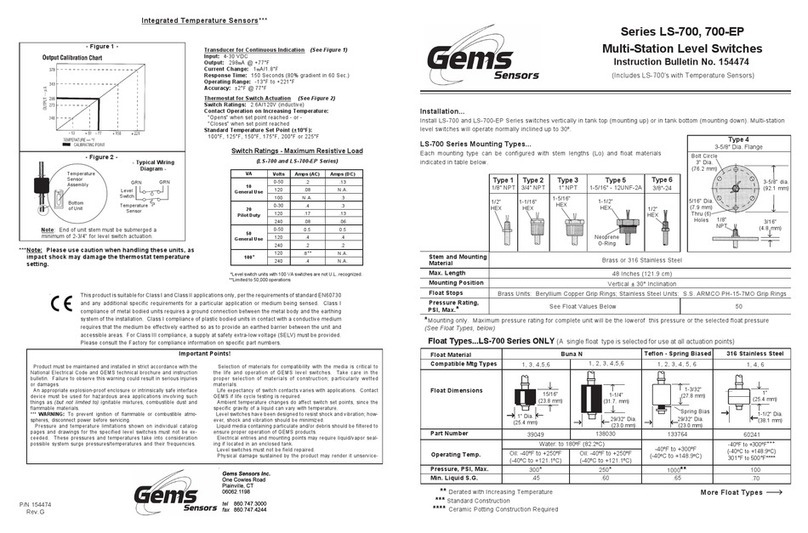

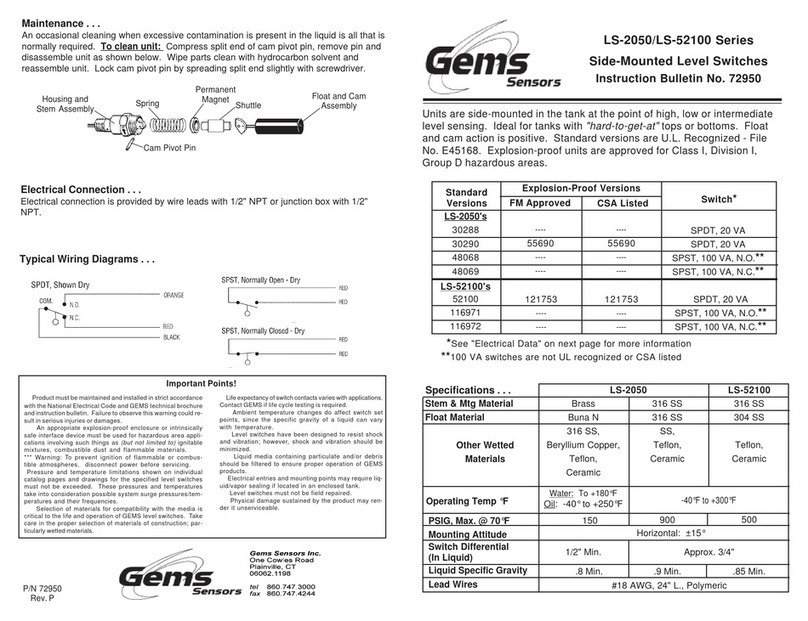

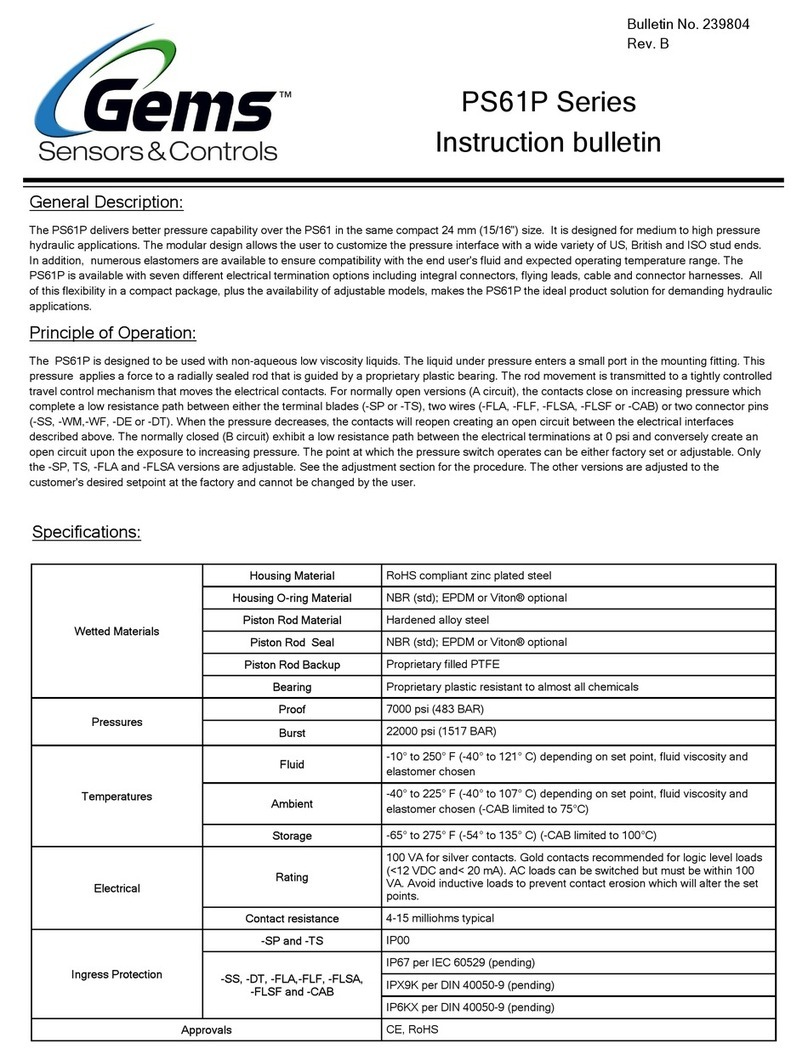

Installation (Cont.)

If it is necessary to locate two switch-points close together, two switch modules can be

positioned side-by-side and located 180oopposite of the flag assembly, as shown.

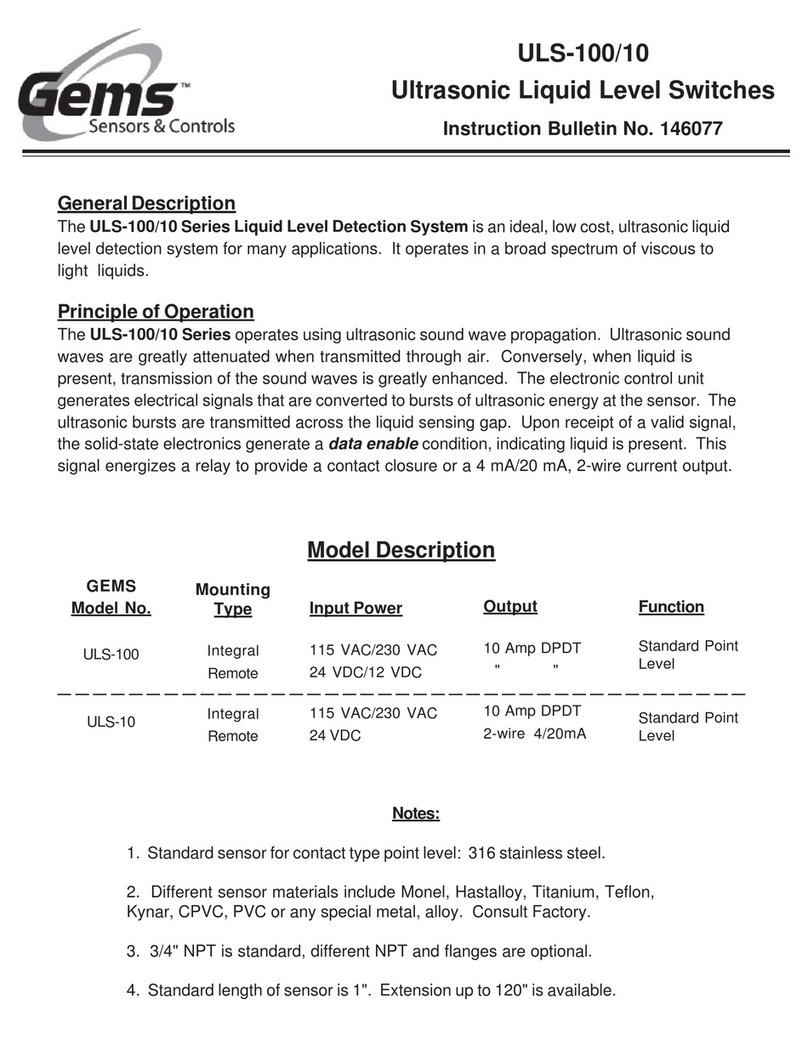

Switch Modules

Part

Number

SureSite

Type

Switch Rating/

Configuration

Max. Fluid

Temp (°F / °C)

Mounting Hardware Switch

Housing

Material

Bracket / Spacer

Block Clamp J-Box

Standard

85350 Standard 20 VA SPST, N.O. or N.C. 300 / 148 N/A N/A N/A Polysulfone

86435 Standard 20 VA SPST, N.O. or N.C. 300 / 148 N/A Included N/A Polysulfone

86567 Mini 20 VA SPST, N.O. or N.C. 300 / 148 N/A Included N/A Polysulfone

87480 Mini / Plastic 20 VA SPST, N.O. or N.C. 300 / 148 N/A N/A N/A Polysulfone

80469 Plastic 20 VA SPST, N.O. or N.C. 300 / 148 N/A N/A N/A Polysulfone

High Temperature

83140 All 20 VA SPST, N.O. or N.C. 750 / 398 Included N/A N/A 316 SS

83150 All 20 VA SPST, N.O. or N.C. 750 / 398 Included N/A N/A 316 SS

84320 All 20 VA SPDT, N.O. or N.C. 750 / 398 Included N/A N/A 316 SS

Explosion-Proof / High Temperature

83100* All 120 VAC, 10 Amp 750 / 398 Included Included Included 316 SS

83110* All 24 VDC, 10 Amp 750 / 398 Included Included Included 316 SS

83120* All 20 VA SPST, N.O. or N.C. 750 / 398 Included Included Included 316 SS

83130* All 20 VA SPST, N.O. or N.C. 750 / 398 Included Included Included 316 SS

84330 All 20 VA SPDT, N.O. or N.C. 750 / 398 Included Included Included 316 SS

* Factory Mutual approved for:

Explosion-proof for Class 1, Division 1, Groups C & D and Class 1, Division 2, Groups B, C & D; Dust ignition proof per Class 2,

Division 1, Groups E, F & G and suitable for Class 3, Division 1, Hazardous Location, Indoors (Ref. File #J.I. 0A8A3.AE). Also

CSA certified for Class 1, Division 1, Groups B, C & D (Ref. Files LR22666-22 and LR22666-24).

Note

For Standard Unit installation instructions, see Mounting Diagram “A”

For all other part numbers listed above, see Mounting diagram “B”, “C” or “D”