ADJUSTING THE SET POINT

All adjustments except for the PS93 are performed while applying a known

pressure (or vacuum) and monitoring the electrical contacts. The PS93 must be

removedfrom the system for adjustment and reinstalled to verify the setpoint.

PS31, PS32, PS51, PS52, PS61, PS62 and PS91:

Using a flat bladed screwdriver, turn the screw clockwise to increase the setpoint

and counterclockwise to decrease the setpoint.

PS83:

Using a flat bladed screwdriver, turn the screw clockwise to decrease the

vacuumsetpointand counterclockwise to increase the vacuum setpoint.

PS93:

Using a 5/64”Allen key, turn the screw clockwise to increase the differential

setpointandcounterclockwise to decrease the differential setpoint.

PS77:

Pressure Adjustment:Usinga3/4”open-endedwrench,loosenthelocknut.

Using a 5/8” open-ended wrench, turn the adjuster clockwise to increase the

setpoint and counterclockwise to decrease the setpoint. Once the desired

setting is obtained tighten the locknut with the 3/4” open-ended wrench while

holdingtheadjusterwiththe5/8”open-endedwrench.

Deadband Adjustment: Turn the thumbwheel clockwise to increase the

deadbandandcounterclockwisetodecreasethedeadband. Deadbandisthe

differenceinpressurebetweentheincreasingpressuresetpoint and decreasing

pressuresetpoint.

PS82:

Using a 1/8”Allen key, turn the screw clockwise to decrease the vacuum

setpoint and counterclockwise to increase the vacuum setpoint.

PS11 and All Other Models Using a 1/8”Allen key, turn the screw clockwise to

increase the setpoint and counterclockwise to decrease the setpoint.

VERIFICATION OF SETPOINT

Verify the new setpoint by slowly increasing and decreasing the pressure (or

vacuum) while monitoring the electrical contacts. Repeat the adjustment

procedure if necessary to obtain the desired setpoint.

REASSEMBLY (IF APPLICABLE)

PS77:

Install the front cover by tightening the four slotted screws.

PS41,PS71,PS72,PS75 and PS76:

Snap the plastic cover onto the electricalhousing.

All Other Models with HC or HN Option:

Install the DIN adapter. Install and tighten the screw.

All Other Models without HC or HN Option:

Install the 1/8”Allen adjustment screw cap at the top of the unit.

PRESSURE EQUIPMENT DIRECTIVE

The pressure switch is designed and

manfactured in accordance with Sound

Engineering Practice as defined by the

Pressure Equipment Directive 97/23/EC.

This pressure switch must not be used

as a “safety accessory” as defined by the

Pressure Equipment, Article 1, Paragraph

2.1.3.

The CE Mark on the unit does not relate

to the Pressure Equipment Directive.

2 3

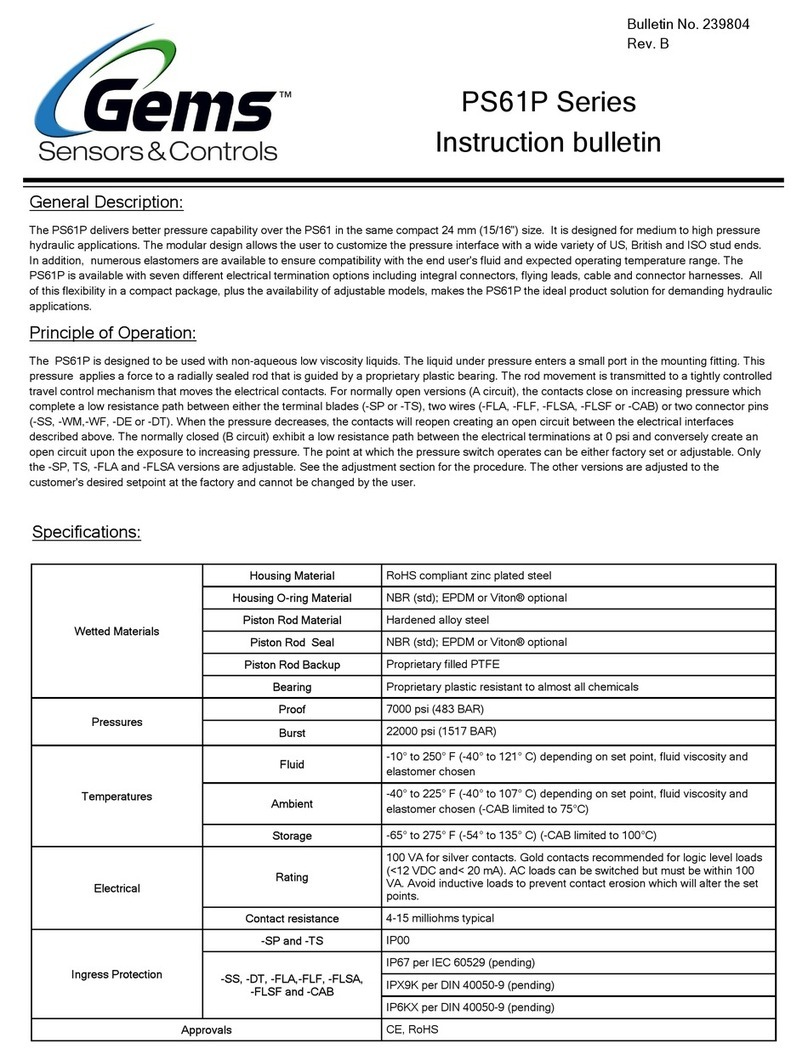

How To Wire a DIN

Connector Code Circuit Wire Colors Connector

Position

Black (Com) B

Red (NO) A

Black (Com) A

OR Green (NC) B

Black (Com) C

Green (NC) B

Red (NO) A

Black (Com) 2

Red (NO) 1

Black (Com) 1

Green (NC) 2

Black (Com) C

Green (NC) B

Red (NO) A

Black (Com) 1

Green (NC) 2

Red (NO) 3

Wiring Chart

WM (uses Delphi

Male Terminal

P/N 12089040

WF (uses Delphi

Female Socket

P/N 12089188)

B

C

DE

Leads & Din

A

B

C

A