CTS12GEN2 RIP-R-STRIPPER®FLOOR COVERING STRIPPER

FORM GOM11121101US, VERSION 1.2

English-EN 4

BEFORE OPERATING

1. BEFORE operating RIP-R-STRIPPER, read this manual plus applicable

safety/operational information supplied by electric breaker manufacturer

to familiarize each operator with correct operating procedures.

2. Visually inspect RIP-R-STRIPPER per MAINTENANCE INSTRUCTIONS

STEPS 5 through 12 of this manual.

3. Determine RIP-R-STRIPPER is in original, factory configuration and has

not been modified in any manner. If questions arise about possible

modifications, contact the Customer Service Department BEFORE

utilization. There is no charge for this service.

4. Always start and stop RIP-R-STRIPPER according to instructions to

minimize possibility of unexpected or uncontrolled chisel/blade

movement. Know how stop unit in an emergency.

Physical Exertion/Body Strain

Operating RIP-R-STRIPPER requires proper physical stamina, mental

alertness and is strenuous. Operators must be in proper physical condition,

mental health and not under the influence of any substance (drugs, alcohol,

etc.) which might impair vision, dexterity or judgment. Take work breaks to

maintain stamina and alertness. If you have condition(s) that might be

aggravated by strenuous work, check with doctor BEFORE operating.

Vibration

Prolonged use of RIP-R-STRIPPER (or other, similar machines) exposes

operator to vibrations which may produce Whitefinger Disease (Raynaud's

Phenomenon) reducing hand's ability to feel and regulate temperature, produce

numbness and burning sensations and may cause nerve, circulation damage

and tissue necrosis. Continuous and regular users should closely monitor

condition of hands and fingers. After each period of use, exercise to restore

normal blood circulation. If any symptoms appear, seek medical advice

immediately.

Noise

Electric breaker mounted to RIP-R-STRIPPER and actual floor covering

removal process creates exposure to high noise emission levels that can result

in hearing loss or damage. Hearing protection is required while operating or

when near operating equipment. Continuous and regular operators should have

hearing checked regularly.

Clothing

Clothing must be sturdy, snug fitting, but allow complete freedom of movement.

Never wear loose fitting jackets, scarves, neckties, jewelry, flared or cuffed

pants or anything that could become caught on controls or moving parts.

Properly secure eyeglasses, hearing aid devices and other medical related

devices. Wear long pants to protect legs. Protect hands and improve grip with

heavy duty, nonslip gloves. Wear and properly lace sturdy boots with nonslip

soles. Steel-toed safety shoes are mandatory. Wear approved safety hard hat

where there is danger of head injuries and/or approved breathing mask where

danger of airborne particulate contamination is present.

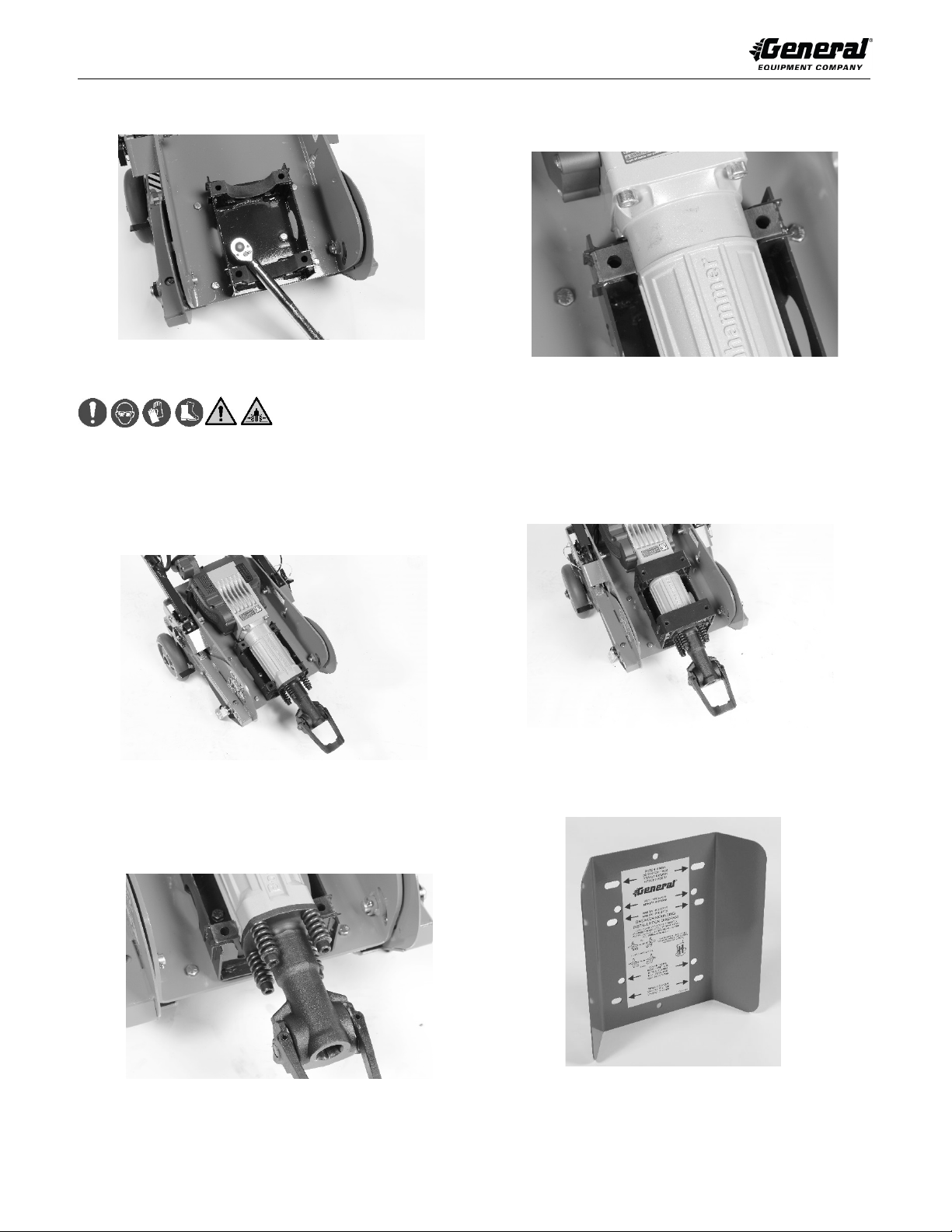

Flying Debris

Floor covering removal process can result in flying debris. Eye protection and

appropriate safety apparel is required when near or operating RIP-R-

STRIPPER. DO NOT operate unit with onlookers or animals close by.

BACK CARE & PROPER LIFTING PROCEDURES

Operators will be required to lift RIP-R-STRIPPER, as demanded by specific

job applications. When lifting, two people are required. Utilize proper lifting

techniques to minimize fatigue and back-related injuries.

Back Anatomy

The human body is supported by the spinal column consisting of thirty bones

called vertebrae, all linked and supported by a series of tiny muscles. Pads

called discs separate each vertebrae, acting as cushions to pressure from

external forces. Spinal column is wrapped by nerve system with three sections

that require being kept in natural alignment to prevent discomfort:

Cervical: From base of neck to the brain.

Thoracic: From middle to lower back.

Lumbar: From lower back to buttocks area.

BACK CARE PREVENTATIVE MEASURES

Most occupational physicians agree on several “universal” preventative

measures an operator should follow to help lower risk of back-related injuries:

1. Maintain proper body weight.

2. Eliminate/reduce use of tobacco. Smoking reduces oxygen supply and

nutrients to discs cushioning vertebrae.

3. Develop a consistent exercise routine.

4. Maintain good posture while walking or sitting.

5. Watch how you twist/bend your body. Twisting/bending incorrectly can

exert too much pressure on one side of your vertebrae.

6. Use firm footing, keep intended path clear before carrying RIP-R-

STRIPPER.

7. Always use proper lifting techniques as described below.

PROPER LIFTING PROCEDURES

The following are guidelines for properly lifting RIP-R-STRIPPER are not

intended to be all inclusive. Plan your path and make sure there are no

obstructions or tripping hazards. Consider how you will set the load. The spinal

column is a very sensitive mechanism. At any given time, improper lifting

procedures can cause damage that can lead to injury.

1. Position your feet a comfortable distance (shoulder width) apart to help

provide necessary balance.

2. Tighten stomach muscles by pulling in your stomach. Keep your back as

straight as possible to keep spine, back muscles/igaments in alignment.

3. Bend at hips and knees as much as possible.

4. Start lifting RIP-R-STRIPPER by thrusting feet while lifting as much as

possible with your leg muscles. Use smooth movements.

5. Once RIP-R-STRIPPER is lifted, keep it close as possible to the body.

Avoid turning at the waist. To turn, pivot your entire body.

6. Keep your shoulders, hips and feet pointed in same direction.

IMPORTANT: Use firm footing, keep intended path clear before carrying

RIP-R-STRIPPER.

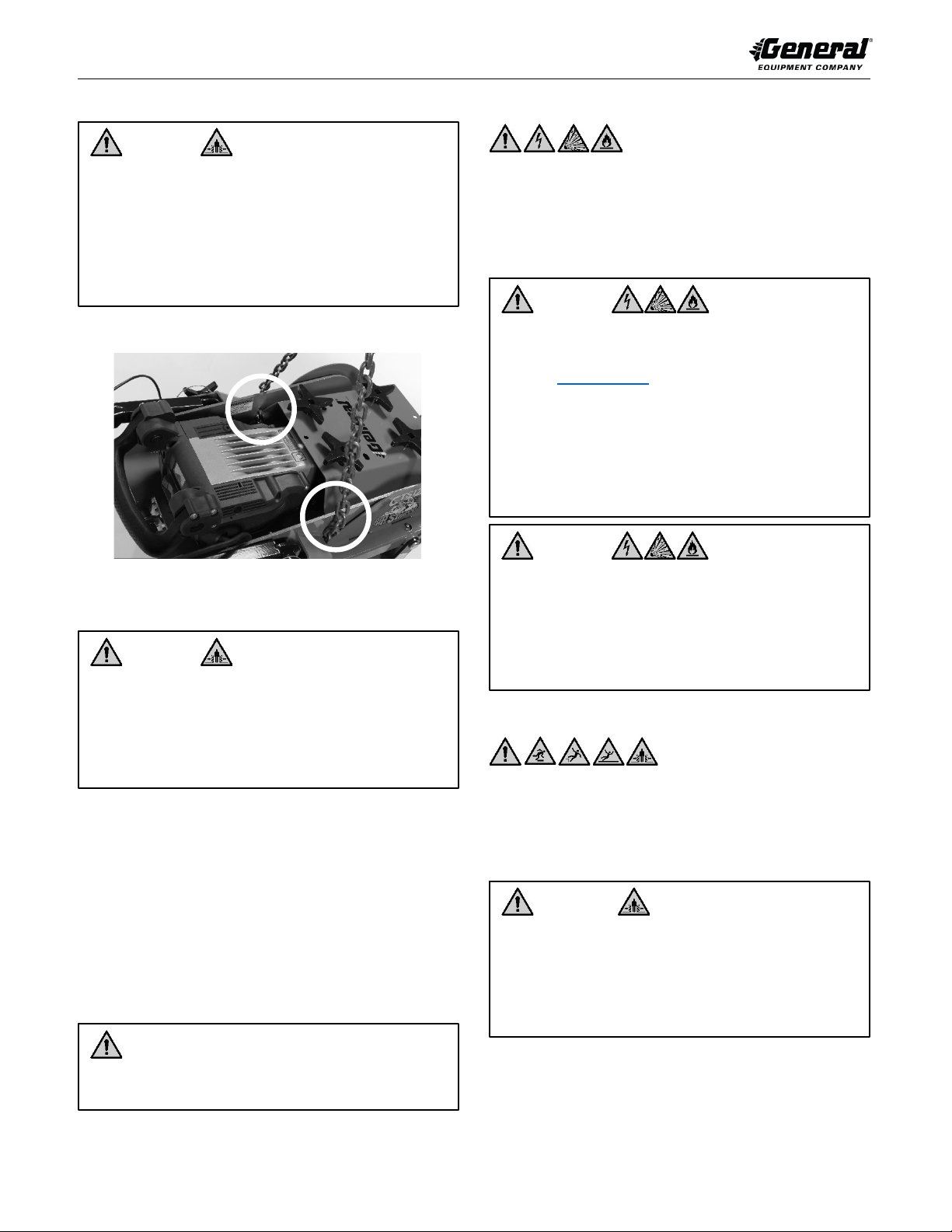

TRANSPORTATION

1. When transporting RIP-R-STRIPPER, remove extension cord and store.

Remove accessory tool from electric breaker according to INSTALLING &

REMOVING ACCESSORY TOOLS in MACHINE SET-UP section of this

manual when in following operating conditions:

a) To and from jobsite.

b) Longer distances while being repositioned on jobsite.

c) Traversing up and down stairways.

d) Performing maintenance and/or repairs.

e) Lifting/lowering from transportation vehicle.

DANGER

•Lifting/lowering and transporting RIP-R-STRIPPER with

accessory tool installed and/or improperly secured can

result in property damage and/or personal injury.

DANGER

•Disconnect extension cord from RIP-R-STRIPPER when

traversing up and down stairs.

•Improperly stored/connected cord can entrap and/or

entangle personnel.

•Such occurrence can result in property damage and/or