cascade corporation J Series User manual

Cascade is a Registered Trademark of Cascade Corporation

cascade

corporation

ERVICE MANUAL SUPPLEMENT

S

Tipping Carton Clamps

J-Series

Manual Number 6914321

NOTE: This manual covers tipping components only. Refer to

J-Series Carton Clamp Service Manual, part number 6883648,

for periodic maintenance, troubleshooting and service to carton

clamp components including arms, carton clamp cylinders, valve

and frame.

BLANK

CONTENTS

i6914321

Page

INTRODUCTION, Section 1

Introduction 1

Special Definitions 1

PERIODIC MAINTENANCE, Section 2

Daily Inspection 2

1000-Hour Maintenance 2

TROUBLESHOOTING, Section 3

General Procedures 3

Truck System Requirements 3

Tools Required 3

Troubleshooting Chart 4

Plumbing 5

Hosing Diagram – Non-Sideshifting Clamp 5

Hydraulic Schematic – Non-Sideshifting Clamp 6

Hosing Diagram – Sideshifting Clamp with Solenoid 7

Hydraulic Schematic – Sideshifting Clamp with Solenoid 8

Tipping Function 9

Supply Circuit Test 9

Tipping Circuit Test 9

Electrical Circuit 10

SERVICE, Section 4

Attachment Removal 11

Arms 12

Clamp Cylinders 12

Clamp Valve 12

Base Unit 12

Back Mounting Frame 13

Removal and Installation 13

Bushing Service 14

Tipping Cylinder 15

Removal and Installation 15

Counterbalance Valve Cartridge Service 16

Cylinder Bushing Service 17

Cylinder Disassembly 18

Cylinder Inspection 18

Cylinder Reassembly 19

Valves 20

Counterbalance Valve Service 20

Solenoid Valve Coil Service 21

SPECIFICATIONS, Section 5

Hydraulics 22

Auxiliary Valve Functions 22

Truck Carriage 23

Torque Values 24

INTRODUCTION

69143211

CATALOG NO.

8J-CCU-2A-12345

SERIAL NO.

PTL012345678

+

7

@

123

+

A2-Z

Cascade Corporation • www.cascorp.com • Icons & Patents: www.cascorp.com/support 6095754

8J-CCU-2A-12345

PTL012345678

CC0244.eps

1.1 Introduction

This manual provides the Periodic Maintenance, Troubleshooting,

Service and Specifications for Cascade J-Series Tipping Carton

Clamps.

In any communication about the attachment, refer to the product

catalog and serial numbers stamped on the nameplate, as shown.

If the nameplate is missing, the numbers can be found stamped

on the frame where the plate was mounted.

IMPORTANT: Cascade J-Series Tipping Carton Clamps are

custom built and size of connecting supply fittings on the

attachment will vary. Consult Cascade if fitting size and type can

not be determined.

NOTE: Specifications are shown in both US and (Metric) units.

All fasteners have a torque value range of ±10% of stated value.

1. 2 Special Definitions

The statements shown appear throughout this manual

where special emphasis is required. Read all WARNINGS

and CAUTIONS before proceeding with any work.

Statements labeled IMPORTANT and NOTE are provided

as additional information of special significance or to make

your job easier.

WARNING - A statement preceded by

WARNING is information that should be

acted upon to prevent bodily injury. A

WARNING is always inside a ruled box.

CAUTION - A statement preceded by CAUTION is

information that should be acted upon to prevent

machine damage.

IMPORTANT - A statement preceded by IMPORTANT is

information that possesses special significance.

NOTE - A statement preceded by NOTE is information that

is handy to know and may make your job easier.

Nameplate

6914321 2

PERIODIC MAINTENANCE

CC0202.eps

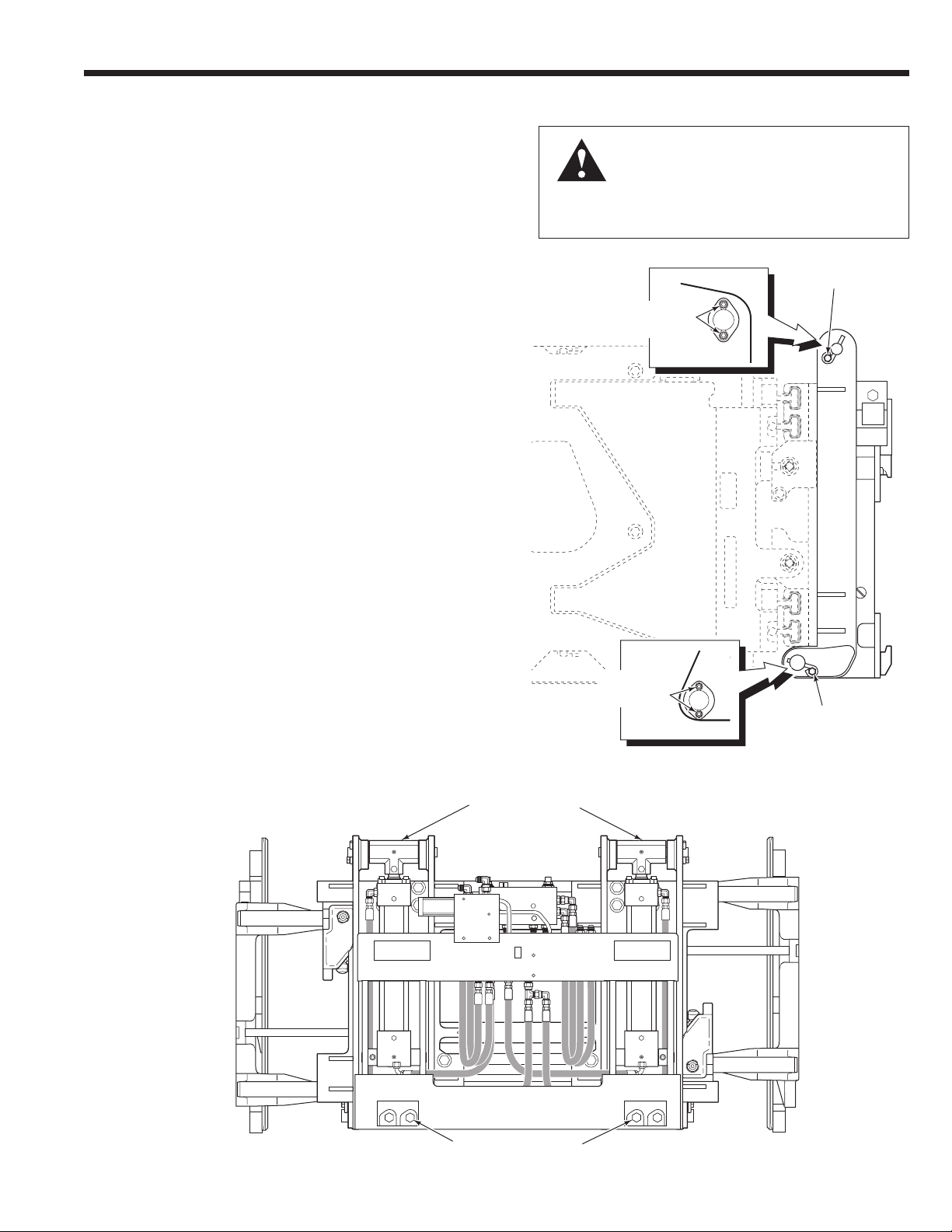

2.1 Daily Inspection

Prior to each shift of truck operation, complete the following

procedures:

• Check for loose or missing bolts, worn or damaged

hoses and hydraulic leaks.

• Check decals and nameplate for legibility.

2.2 1000-Hour Maintenance

After each 1000 hours of truck operation, in addition to the

daily inspection, perform the following procedures:

• Check lower mounting hooks for engagement. Hooks

should be tight against lower carriage. If adjustment is

necessary, refer to Section 4.1, Step 3.

• Tighten lower hook capscrews to 165 ft.-lbs. (225 Nm).

• Inspect all tipping pivot bushings and pins for wear.

Replace as needed.

• Tighten tipping eye pin or retainer capscrews to:

Retainer Capscrews – 14 ft.-lbs. (19 Nm)

Eye Pin Capscrew – 28 ft.-lbs. (38 Nm)

WARNING: After completing any service

procedure, always test the attachment

through five complete cycles. First test

the attachment empty, then test with a load

to make sure the attachment operates

correctly before returning to the job.

OR

OR

Side View

IMPORTANT: This section covers periodic maintenance

for tipping components only. In addition to the periodic

maintenance below, perform the periodic maintenance

found in J-Series Carton Clamp Service Manual, part

number 6883648.

Eye Pin

Capscrew

Eye Pin

Capscrew

Tipping Cylinders

Lower Mounting Hooks

Back (Driver's) View

Retainer

Capscrews

Retainer

Capscrews

CC0203.eps

TROUBLESHOOTING

69143213

3.1 General Procedures

IMPORTANT: Troubleshooting the SIDESHIFT or CLAMP

circuits can be found in J-Series Carton Clamp Service

Manual, part no. 6883648.

3.1-1 Truck System Requirements

• Truck hydraulic pressure should be within the range

shown in Specifications, Section 5.1. PRESSURE TO

THE ATTACHMENT MUST NOT EXCEED:

Low Pressure – 2755 Psi (189 bar)

High Pressure – 3625 Psi (250 bar)

• Hydraulic flow should be within the volume range as

shown in Specifications, Section 5.1.

• Hydraulic fluid supplied to the attachment must meet the

requirements as shown in Specifications, Section 5.1.

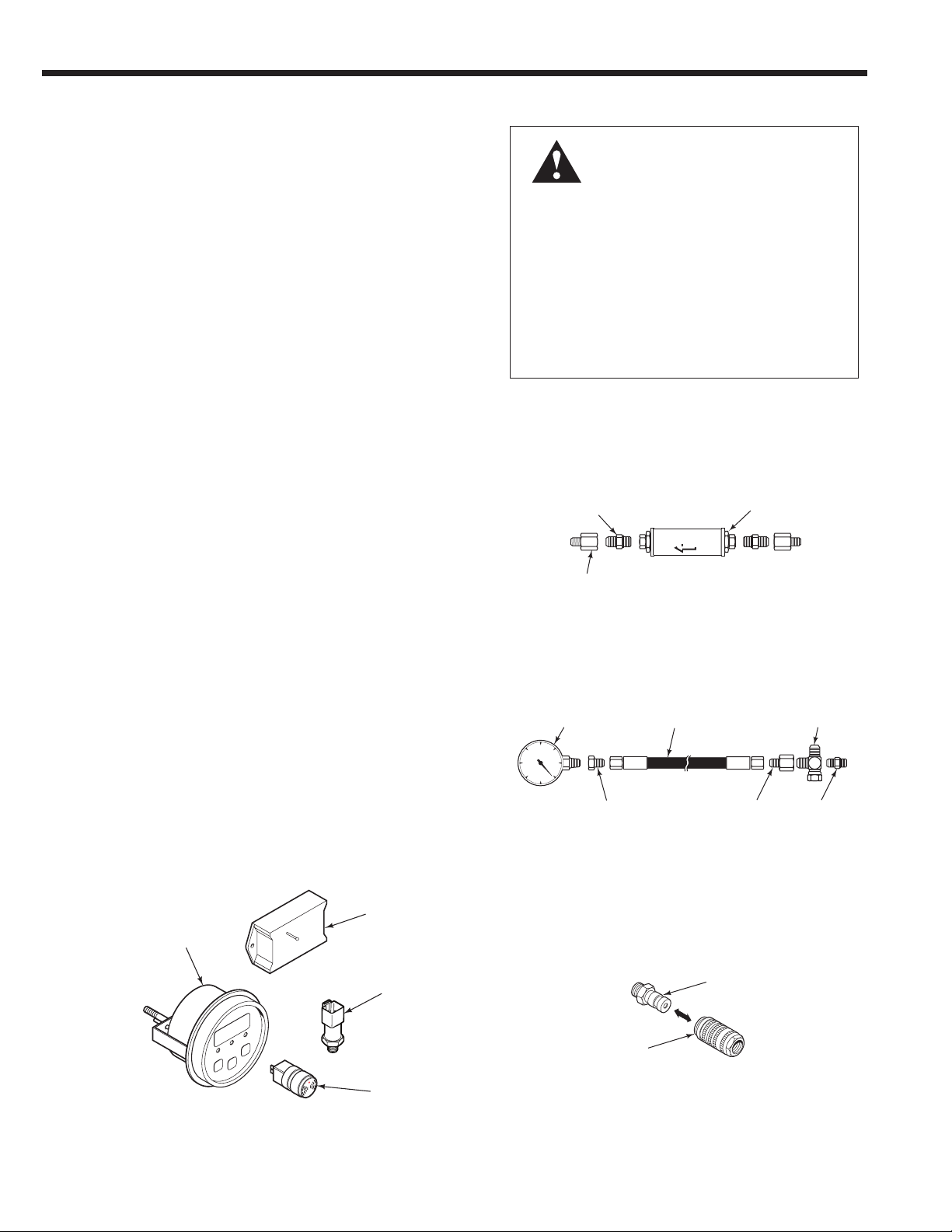

3.1-2 Tools Required

In addition to a normal selection of hand tools, the following

will be required:

• Inline Flow Meter Kit:

20 GPM (75 L/min.) - Cascade Part No. 671477.

• Pressure Gauge Kit:

5000 psi (345 bar) - Cascade Part No. 671212. Two kits

are required.

OR

Wireless Pressure Monitor Kit:

Pressure transducers monitor the hydraulic pressure

and wirelessly transmit the data to the receiver display.

• Assorted fittings and hoses to adapt the gauge and flow

meter to the components being tested.

WARNING: Before servicing any

hydraulic component, relieve pressure

in the system. Turn the truck off and

move the truck auxiliary control valves

several times in both directions.

After completing any service procedure, test the

attachment through several cycles. First test

the attachment empty to bleed any air trapped

in the system to the truck tank. Then test the

attachment with a load to be sure it operates

correctly before returning to the job.

Stay clear of the load while testing. Do not raise

the load more than 4 in. (10 cm) off the floor while

testing.

Pressure

Gauge ▲

No. 6 and No. 8

JIC Swivel Tee

No. 4-6 Pipe/JIC ▲

No. 6-6 Hose ▲

(2) No. 6-8 JIC Reducer

Flow Meter

No. 4, No. 6 ▲

and No. 8

JIC/O-Ring

No. 6-8 JIC

Reducer

(2) No. 8-12 JIC/

O-Ring

Diagnostic Quick-Disconnects

Male Straight Thread

O-Ring Coupler:

No. 4 (Part No. 212282) ▲

No. 5 (Part No. 210378)

No. 6 (Part No. 678592)

Female JIC Thread Coupler:

No. 4 (Part No. 210385) ▲

No. 6 (Part No. 678591)

▲Included in Diagnostics Kit 394382.

GA0013.eps

GA0014.eps

AC0127.eps

AC1983.eps

Receiver/Display

Transmitter

Pressure

Transducer

Alarm

(if equipped)

Flow Meter Kit

671477 – 75 L/min (20 GPM)

Pressure Gauge Kit

671212

Wireless Pressure Monitor Kits

6803614 – 12V Kit

6815672 – 12V Kit, includes alarm

6803617 – 24V-48V Kit

6815675 – 24V-48V Kit, includes alarm

6914321

TROUBLESHOOTING

4

3.1-3 Troubleshooting Chart

Determine All The Facts

It is important that all the facts regarding the

problem are gathered before beginning service

procedures. The first step is to talk to the equipment

operator. Ask for a complete description of the

malfunction. The following guidelines can then be

used as a starting point to begin troubleshooting

procedures:

Tipping Circuit

• Attachment does not tip forward or back.

To correct this problem, see Section 3.3.

TROUBLESHOOTING

69143215

CC0167.eps

3.2 Plumbing

3.2-1 Hosing Diagram – Non-Sideshifting Clamp

TIP BACK

PRESSURE

RETURN

NOTE: For TIP FORWARD reverse the

colors shown.

2-Port Hose Reel or

Internal Hose Reel

Tipping

Cylinders

2-Port Hose Reel or

Internal Hose Reel

Hose Terminal

Arm Cylinders

Arm Cylinders

Carton Clamp Valve

Carton Clamp Valve

TIP

Truck

Auxiliary

Valve

CLAMP

Truck

Auxiliary

Valve

CLAMP

PRESSURE

RETURN

NOTE: For OPEN reverse the

colors shown.

To CLAMP

Hose Terminal

Counterbalance

Valve

6914321

TROUBLESHOOTING

6

OP,

LH

CL,

RH

OP,

RH

OP

CL

CL,

LH

3

1

2

CC0168.eps

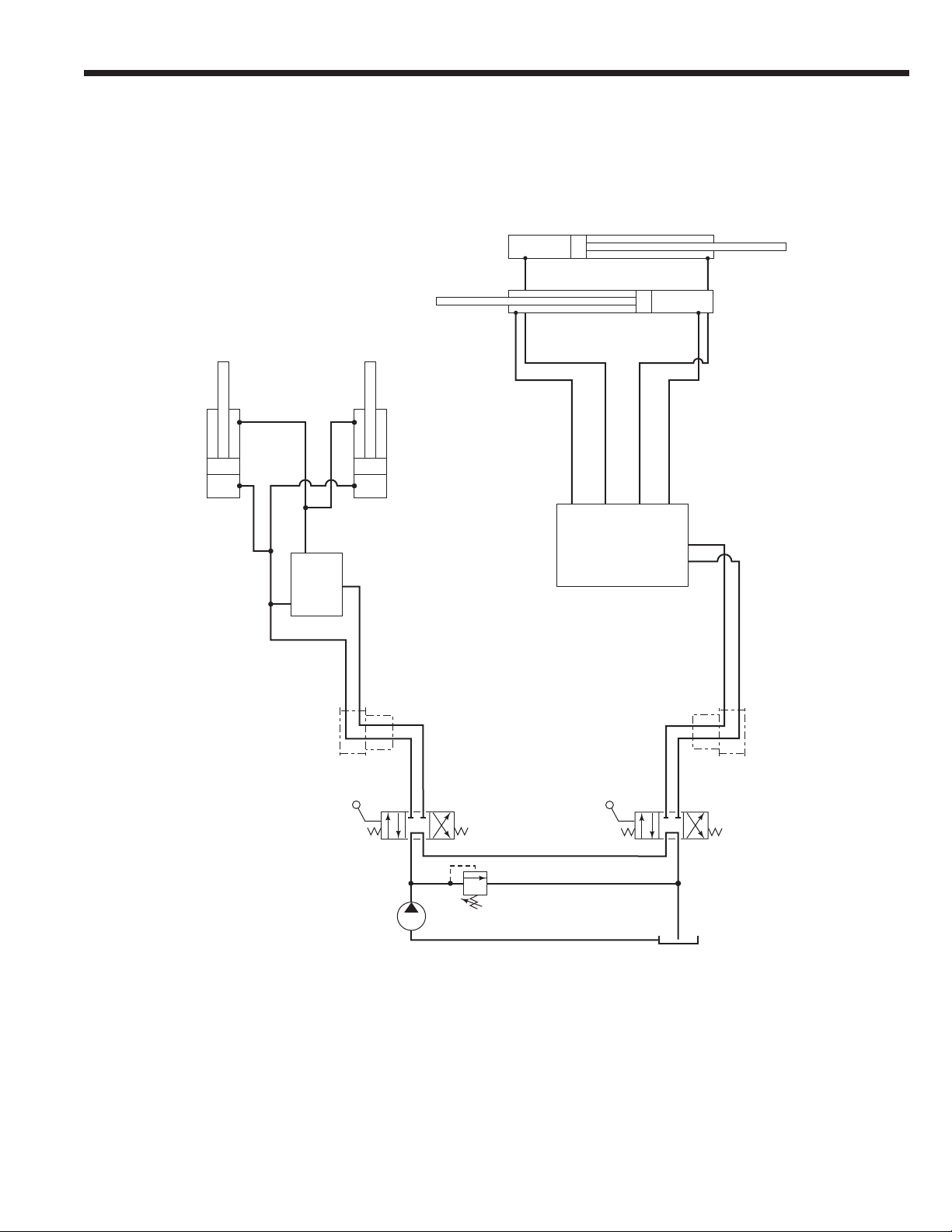

3.2-2 Hydraulic Schematic – Non-Sideshifting Clamp

Arm Cylinders

Counterbalance

Valve

Carton Clamp Valve

Tipping Cylinders

2-Port Hose Reel or

Internal Hose Reel

2-Port Hose Reel or

Internal Hose Reel

TIP

Truck

Auxiliary

Valve

CLAMP

Truck

Auxiliary

Valve

Truck Pump

Truck Relief

Valve

Truck Tank

TROUBLESHOOTING

69143217

CC0171.eps

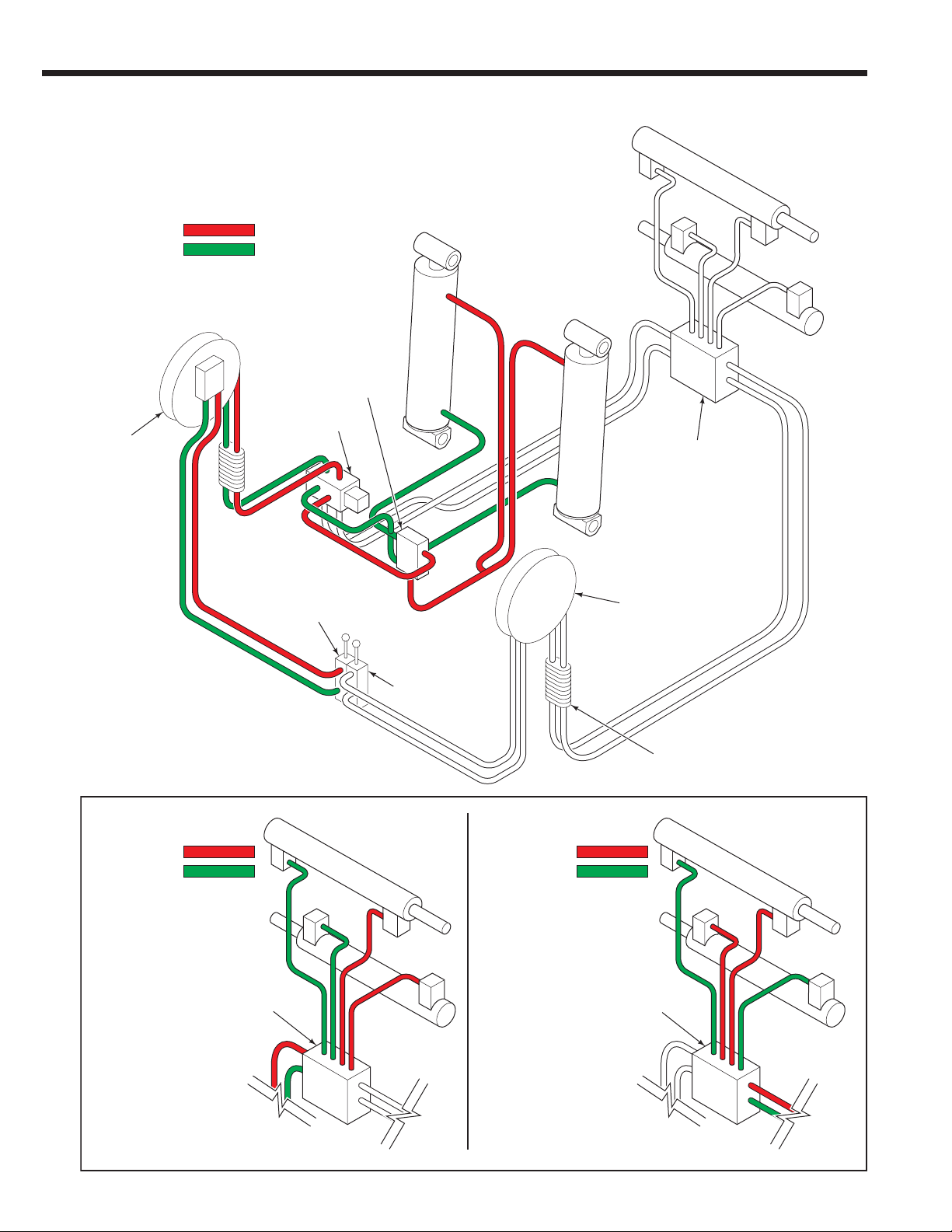

3.2-5 Hosing Diagram –

Sideshifting Clamp with Solenoid

TIP BACK

PRESSURE

RETURN

NOTE: For TIP FORWARD reverse the

colors shown.

SIDESHIFT LEFT

PRESSURE

RETURN

NOTE: For SIDESHIFT

RIGHT reverse the

colors shown.

CLAMP

PRESSURE

RETURN

NOTE: For OPEN, reverse

the colors shown.

Tipping

Cylinders

Arm Cylinders

Arm Cylinders Arm Cylinders

2-Port Hose Reel or

Internal Hose Reel

2-Port

Hose Reel

or Internal

Hose Reel

To Hose

Terminal

To Hose

Terminal

To Solenoid

Valve

To Solenoid

Valve

TIP and SIDESHIFT

Truck Auxiliary Valve

CLAMP Truck

Auxiliary Valve

Counterbalance Valve

Solenoid Valve

Carton Clamp Valve

Hose Terminal

Carton Clamp Valve Carton Clamp Valve

Other manuals for J Series

2

Table of contents

Other cascade corporation Power Tools manuals