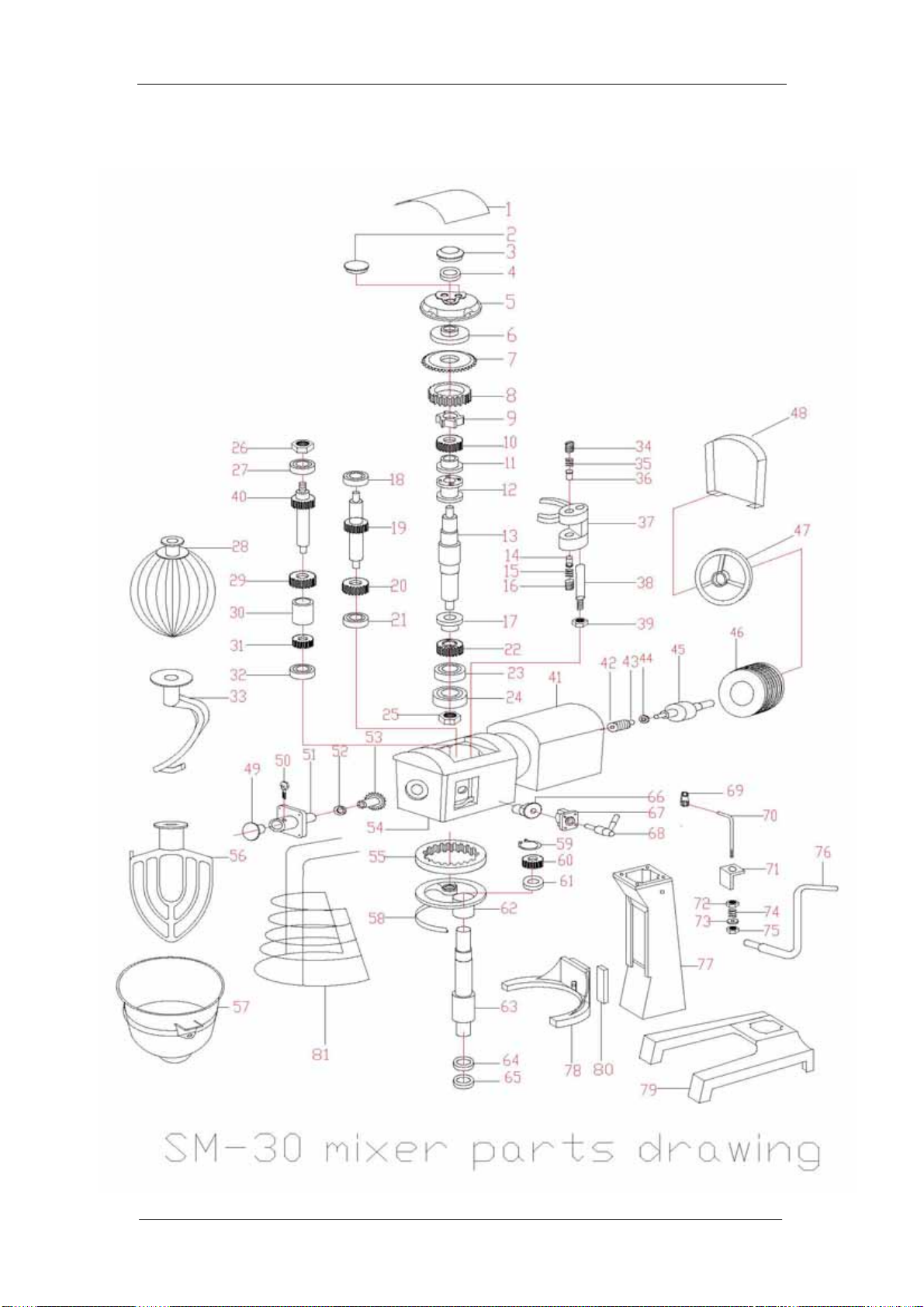

GEW130 Mixeroperationinstruction Rev.a

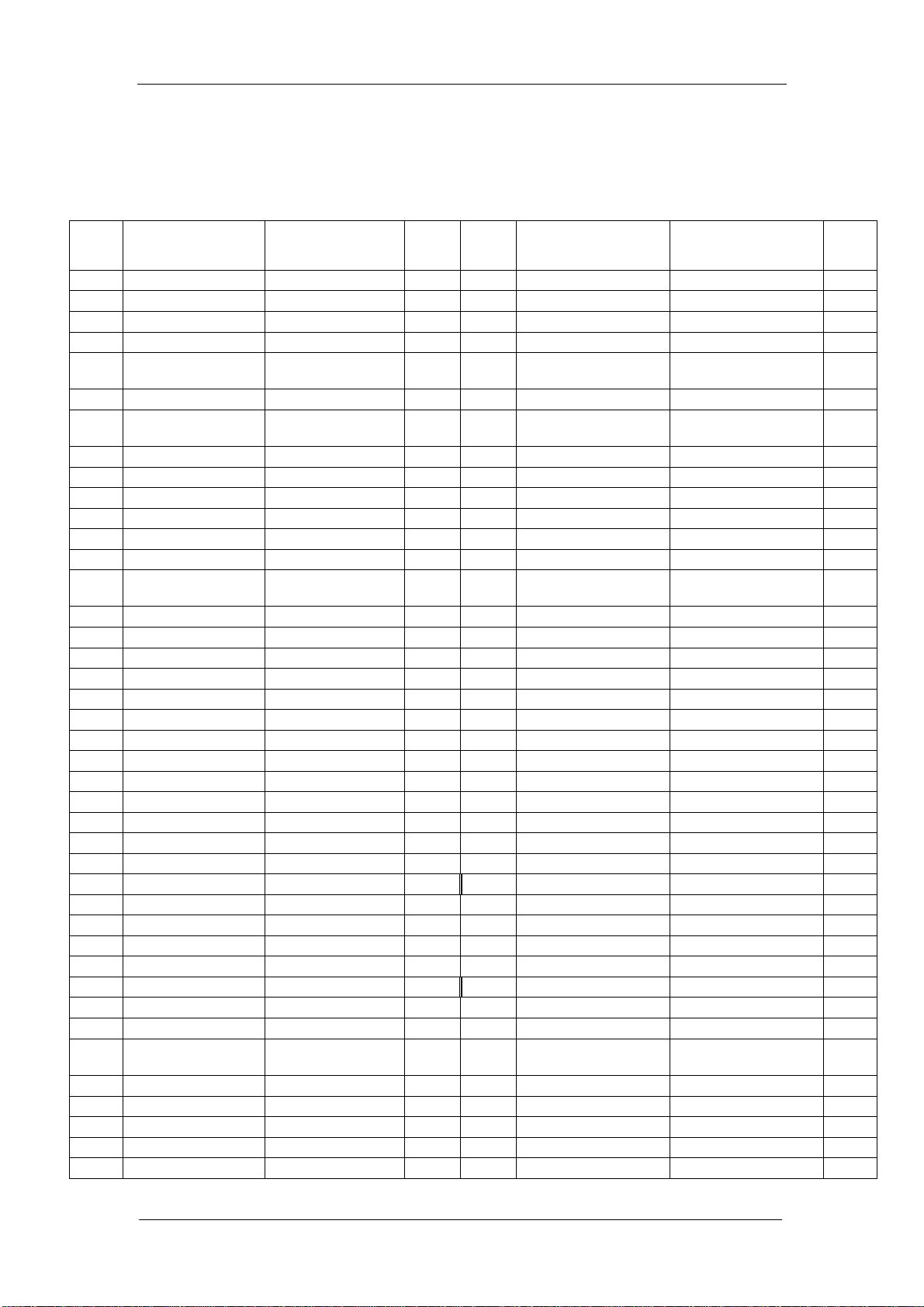

8. list of part number

Date 2005-1-1

#Part # Description #Part # Description

1 SM300-01-09 cover 41 SM300-01-04 case

2 外购件 flat valve cap 42 SM300-01-40 worm wheel

3 SM300-01-14 top batter valve cap 43 standard part pin

4 203 bearing 44 SM300-01-41 bushing

5 SM300-01-05

transmission shaft

support 45

外购件 motor rotator

6 SM300-01-16 spacer-lower 46 外购件 motor stator

7 SM300-01-13 gear 47 SM300-01-03

back bearing

suppoter

8 SM300-01-19-01 gear 48 SM300-01-45 back cover, Motor

9 SM300-01-19-02 gear 49 SM300-01-24 plug attachment hub

10 SM300-01-20 gear 50 SM300-01-01 plug

11 SM20-01-21 bushing 51 SM300-01-23 attachment hub

12 SM300-01-25 sleeve 52 SM20-01-26 ring

13 SM300-01-17 main shaft 53 SM300-01-22 gear

14 standard part

retainer-spring(shift

er yoke) 54 SM300-01-18 handpiece

15 外购件 spring 55 SM300-01-30 internal gear

16 standard part pin 56 SM300-09-03 Flat Beater

17 SM300-01-27 bushing 57 SM300-08-00 bowl

18 standard part bearing 58 SM300-01-32 hood ring

19 SM300-01-06 shaft worm gear 59 Spring-59 spring

20 SM300-01-10 gear 60 SM300-01-31 planet

21 standard part bearing 61 standard part bearing

22 SM300-01-26 gear 62 SM300-01-33 operating shelf

23 standard part bearing 63 SM300-01-34 working shaft

24 seal-24 #24, oil seal 64 standard part bearing

25 standard part nut 65 seal-65 #65, oil seal

26 standard part nut 66 SM20-01-39-01 cam-gear shifter

27 standard part bearing 67 SM20-01-39-02 plate-shifter index

28 SM300-09-01 Wire Whip 68 SM300-01-02 handle-shifter

29 SM300-01-11 gear 69 SM300-06-11 crank lever

30 SM300-01-38 bushing 70 SM300-06-10 connecting rod

31 SM300-01-35 gear 71 SM300-06-09 angle iron

32 standard part bearing 72 standard part nut

33 SM300-09-02 hook 73 standard part ring

34 standard part pin 74 外购件 spring

35 外购件 spring 75 standard part nut

36 standard part

retainer-spring(shift

er yoke) 76 SM300-06-12 handle-shifter

37 SM300-01-42 shifting yoke 77 SM300-06-01 stud

38 SM300-01-43 declutch shift shaft 78 SM300-06-05 support

39 standard part nut 79 SM300-06-06 base

40 SM300-01-12 gear shaft 80 SM300-06-07 slide squeeze head

81 SM300-03-01-00 Safety guard

page 6 of 6