RULES FOR SAFE OPERATION

To help ensure safe operation, please take a moment to learn the machine's applications and limitations,

as well as

potential hazards. General® MFG disclaims any real or implied warranty and holds itself harmless for any iniury that may

result from improper use of its equipment.

1.

Do not

operate the saw when tired, distracted, or

under the effects of drugs, alcohol or any

medication that impairs reflexes or alertness.

2.

The working area should be well lit, clean and free

of debris.

3.

Keep children and visitors at a safe distance when

the saw is in operation; do not permit them to

operate the saw.

4.

Childproof and tamper proof your shop and all

machinery with locks, master electrical switches

and switch keys, to prevent unauthorized or

unsupervised use.

5.

Stay alert!

Give your work your undivided

attention. Even a momentary distraction can lead to

serious injury.

6.

Fine particulate dust is a carcinogen that can be

hazardous to health. Work in a well-ventilated area

and whenever possible use a dust collector and

wear eye, ear and respiratory protection devices.

7.

Do not wear loose clothing, gloves, bracelets, neck-

laces or other jewelry while the saw is in operation.

Wear protective hair covering to contain long hair

and wear non-slip footwear.

8.

Be sure that adjusting wrenches, tools, drinks and

other clutter are removed from the machine and/or

the feed table surface before operating.

9.

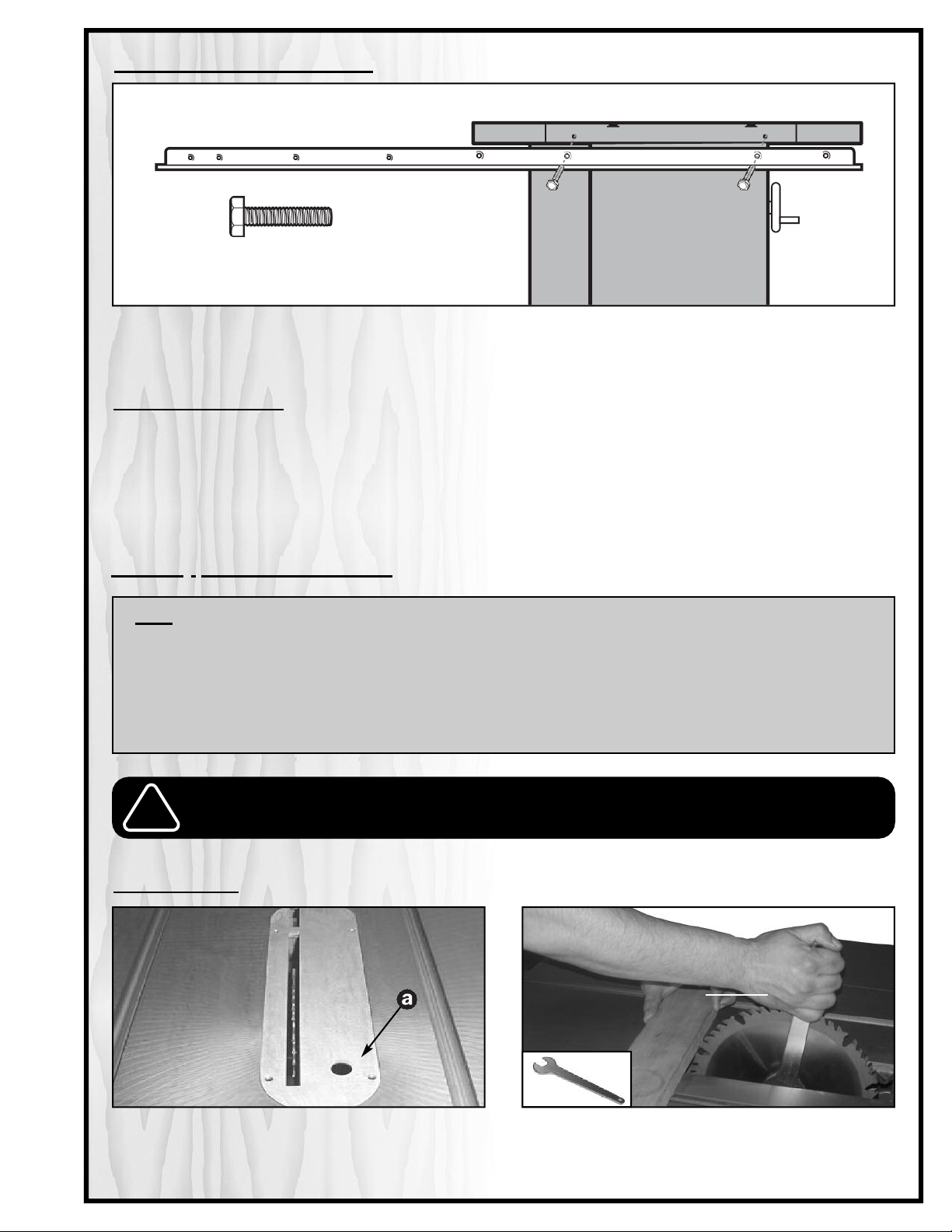

Keep hands well away from the blade and all

mo

ving parts. Use a brush, not hands, to clear

away

chips and dust.

10.

Be sure that the blade is securely installed and in

proper cutting direction before operation.

11.

Be sure the blade has gained full operating speed

before beginning to cut.

12.

Always use a clean, properly sharpened blade.

Dirty or dull blades are unsafe and can lead to

accidents.

13.

If using a power feeder, stop the feeder before stop-

ping the table saw.

14.

Do not push or force stock into the blade. The saw

will perform better and more safely when working

at the rate for which it was designed.

15.

Use suitable support when cutting stock that does

not have a flat surface. Always hold stock firmly

against the fence when ripping, or against the miter

gauge when cross cutting.

16.

To minimize risk of injury in the event of workpiece

kickback, never stand directly in-line with the blade

or in the potential kickback path of the work piece.

17.

Avoid working from awkward or off balance

positions. Do not overreach while cutting; keep

both feet on the floor. Never lean over or reach

over the blade and never pull the work piece over

the blade

from behind. Use out feed support or have

an assis

tant help when ripping long material.

18.

Keep blade guards in place and in working order. If

a guard must be removed for maintenance or

cleaning, be sure it is properly reattached before

using the tool again.

19.

Never leave the machine running with the power

on when not in operation.

20.

Use of parts and accessories NOT recommended by

GENERAL® MFG may result in equipment mal-

function or risk of injury.

21.

Never stand on machinery. Serious injury could

result if the tool is tipped over or if the blade is

unin

tentionally contacted.

22.

Always disconnect tool from power before servicing

or changing accessories such as blades, or before

performing any maintenance, cleaning or

adjust

ments, or if the machine will be left

unattended.

23.

Make sure that switch is in "OFF" position before

plugging in the power cord.

24.

Make sure the tool is properly grounded. If equip-

ped with a 3-prong plug it should be used with a

three-pole receptacle. Never remove the third

prong.

25.

Do not use this saw for other than its intended use. If

used for other purposes, GENERAL® MFG disclaims

any real implied warranty and holds itself harmless

for any injury, which may result from that use.