123

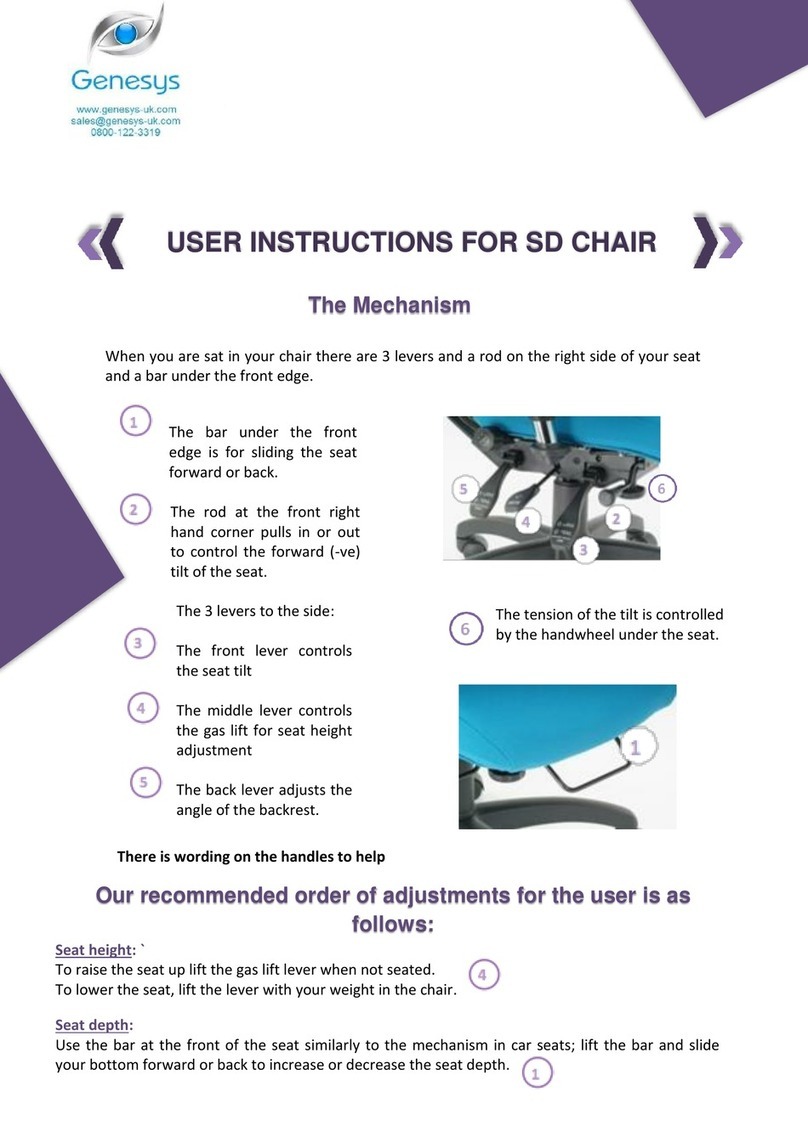

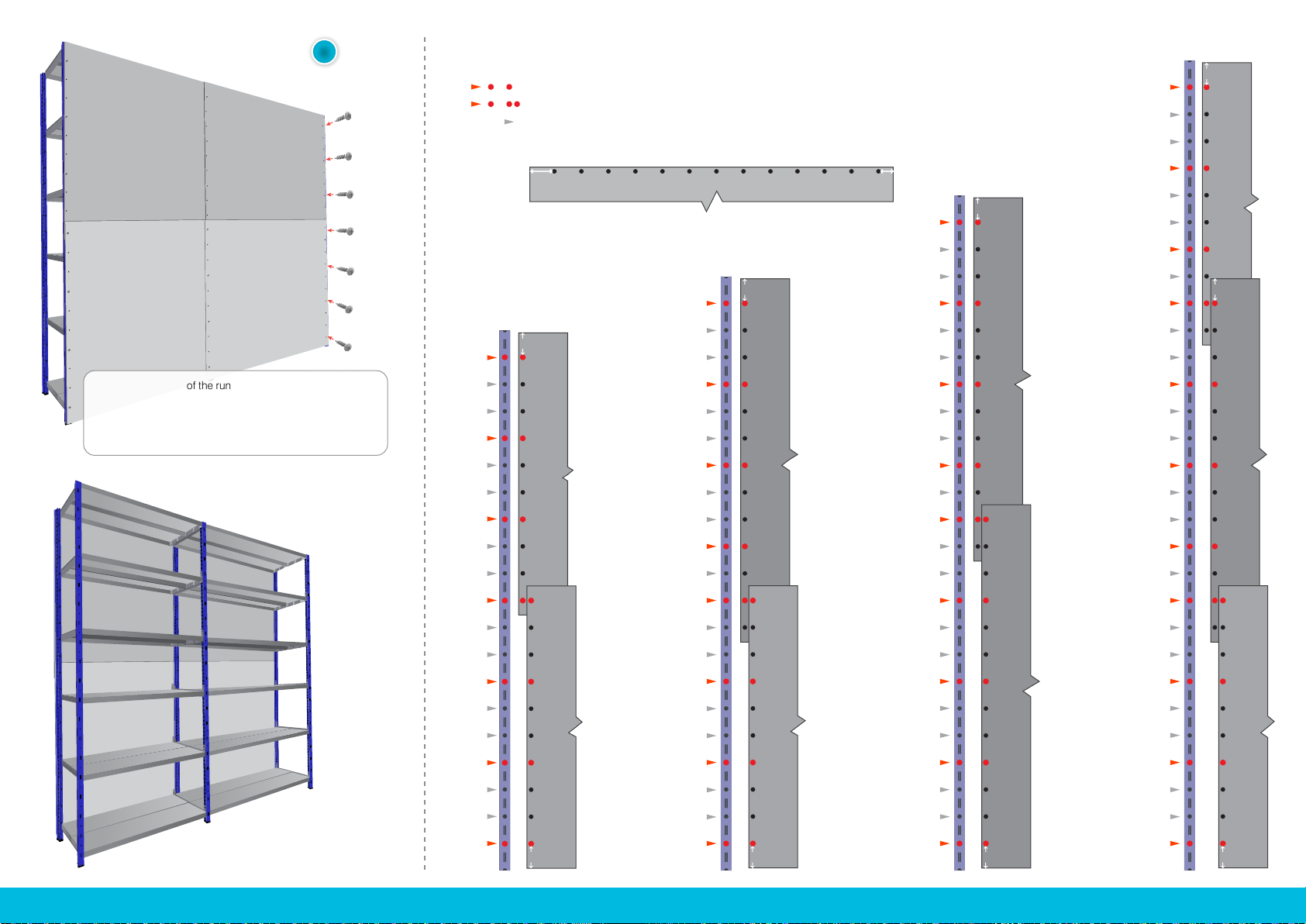

Back Mesh Panel Installation

Mesh back panels can be attached at any time

after the bay has been assembled.

1. Push the arrow tip of the cable tie through the

hole on the back of the upright.

2. Position the mesh as required and loop the tie

around the outer wire of the mesh.

3. Repeat the process along the whole height of

the bay and on both sides of the mesh. Use as

many ties as required - approx 2-3 ties per meter

per side. To cover the whole back of the bay, you

will need to use 2 or more mesh panels and use

basic cable ties to join the panels together.

4. To prevent goods falling off at the back behind

the shelf and the mesh, push the black clip onto

the edge of the shelf and run through another

cable tie to connect the clip and the back mesh.

Use the clip on every 2nd shelf.

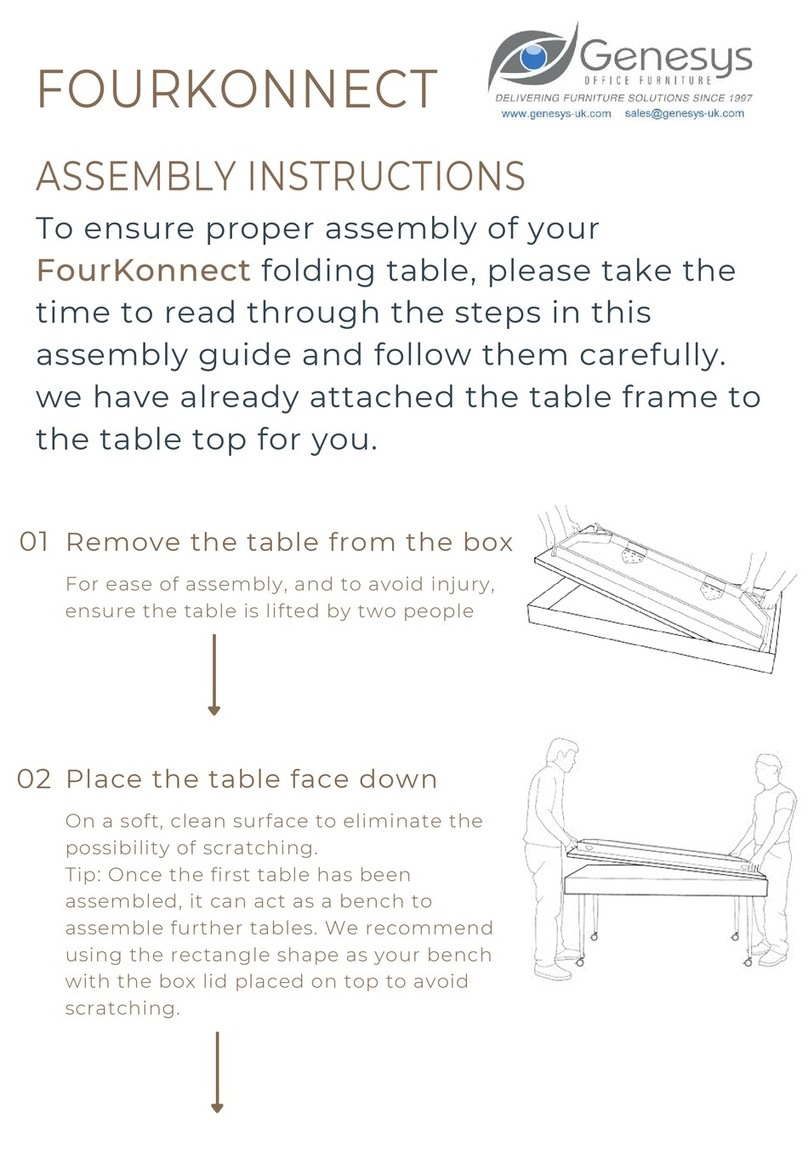

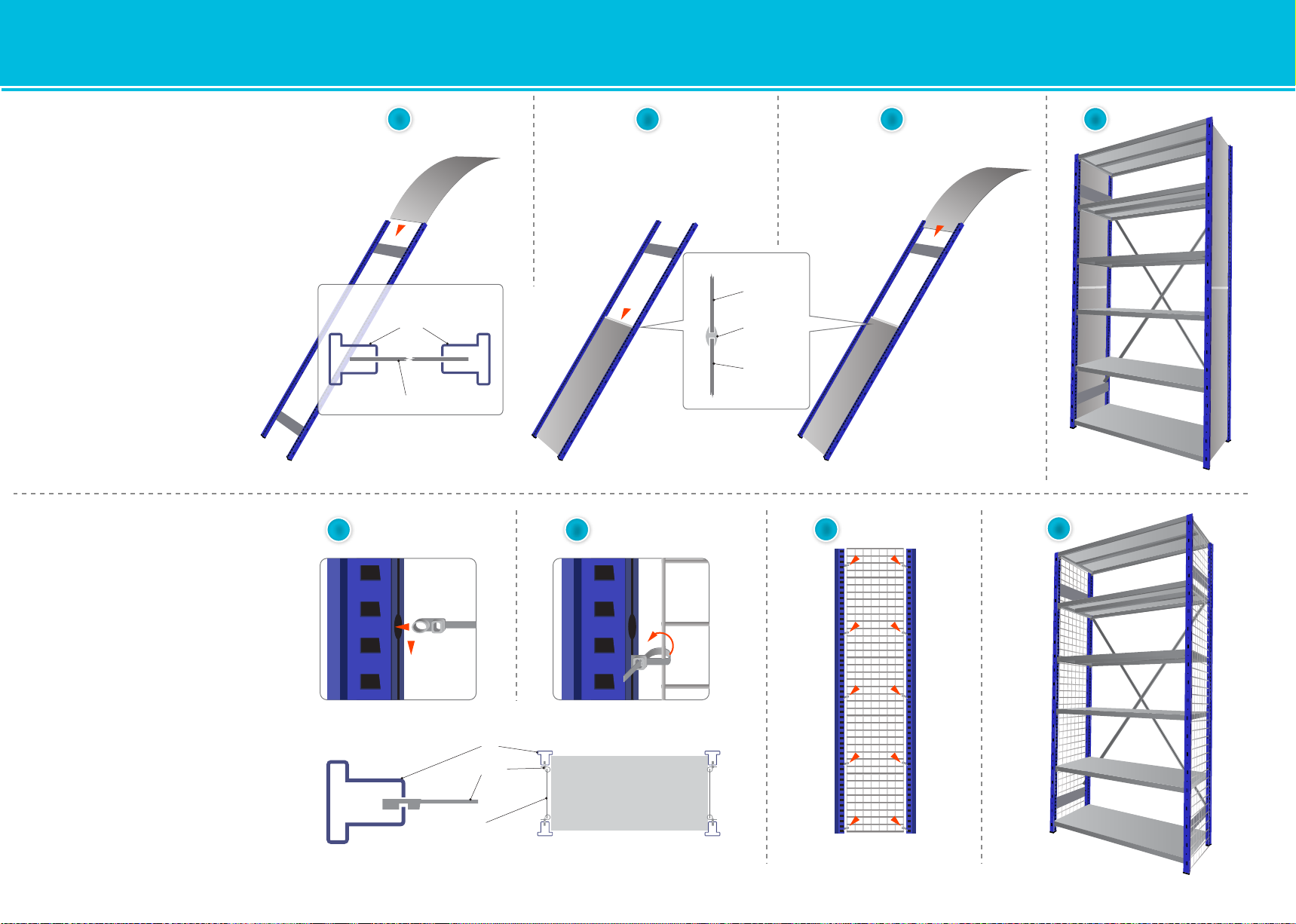

Hook-in Back Cladding Installation

Depending on the height of the bay, use a

combination of 400 and 500 mm tall panels.

Do not use any bracing on bays with hook-in back

cladding.

1. Place the first back cladding pannel to the back

of the bay by inserting the hooks on the panel to

the vertical slots at the back of each upright.The

first panel is situated 100mm off the floor.

2. Continue placing the other panels from the

bottom up, on top of each other.

3. Insert the U Clip to both uprights just above the

top hook of the top back panel to prevent the

panels being accidentally knocked out.

2

4

Uprights

Cable Ties Back Mesh Panel

Shelf

Back Mesh Panel

Shelf

Clip

Cable Tie

1

3

EXPO BACK CLADDING Assembly Instructions