WARRANTY ..........................................................................................................................................

SAFETY INSTRUCTIONS.....................................................................................................................

GERMAN SAFETY INSTRUCTIONS ...................................................................................................

....................................................................................

1.1 OPERATION MANUAL CONTENT .................................................................................................

1.2 INTRODUCTION .............................................................................................................................

1.2.1 General description ................................................................................................................

1.2.2 Models covered ......................................................................................................................

1.2.3 Features and options .............................................................................................................

1.2.4 Multiple output power system .................................................................................................

1.2.5 Control via the serial communication port ..............................................................................

1.2.6 Analog voltage programming and monitoring .................................................................. ......

1.2.7 Parallel operation ...................................................................................................................

1.2.8 Output connections ................................................................................................................

1.2.9 Cooling and mechanical construction ....................................................................................

1.3 ACCESSORIES ...............................................................................................................................

1.3.1 General ..................................................................................................................................

1.3.2 Serial link cable ......................................................................................................................

1.3.3 Misc. hardware .......................................................................................................................

1.3.4 AC cables ...............................................................................................................................

1.3.5 Serial Port Cables ..................................................................................................................

...................................................................................................

2.1 OUTPUT RATING ...........................................................................................................................

2.2 INPUT CHARACTERISTICS ..........................................................................................................

2.3 CONSTANT VOLTAGE MODE .......................................................................................................

2.4 CONSTANT CURRENT MODE ......................................................................................................

2.5 ANALOG PROGRAMMING AND MONITORING ............................................................................

2.6 PROGRAMMING AND READBACK ...............................................................................................

2.7 PROTECTIVE FUNCTIONS ...........................................................................................................

2.8 FRONT PANEL ................................................................................................................................

2.9 ENVIRONMENTAL CONDITIONS ..................................................................................................

2.10 MECHANICAL ..............................................................................................................................

2.11 SAFETY/EMC ...............................................................................................................................

2.12 SUPPLEMENTAL CHARACTERISTICS .......................................................................................

2.13 OUTLINE DRAWINGS .................................................................................................................

.......................................................................................................

3.1 GENERAL .......................................................................................................................................

3.2 PREPARATION FOR USE ..............................................................................................................

3.3 INITIAL INSPECTION .....................................................................................................................

3.4 RACK MOUNTING ..........................................................................................................................

3.4.1 To install the power supply in a rack .......................................................................................

3.4.2 Rack mount slides ..................................................................................................................

3.5 LOCATION MOUNTING AND COOLING .......................................................................................

3.6 AC SOURCE REQUIREMENTS .....................................................................................................

3.7 AC INPUT POWER CONNECTION ................................................................................................

3.7.1 AC input connector, 1500W models .......................................................................................

3.7.2 AC input connector, 750W models .........................................................................................

3.7.3 AC input cord ..........................................................................................................................

3.7.4 AC input wire connection, 1500W models ..............................................................................

3.8 TURN-ON CHECKOUT PROCEDURE ...........................................................................................

3.8.1 General ...................................................................................................................................

3.8.2 Prior to operation ...................................................................................................................

3.8.3 Constant voltage check ..........................................................................................................

3.8.4 Constant current check ..........................................................................................................

3.8.5 OVP check .............................................................................................................................

3.8.6 UVL check ..............................................................................................................................

3.8.7 Foldback check ......................................................................................................................

3.8.8 Address setting ......................................................................................................................

3.8.9 Baud rate setting ....................................................................................................................

CHAPTER 1 GENERAL INFORMATION

CHAPTER 2 SPECIFICATIONS

CHAPTER 3 INSTALLATION

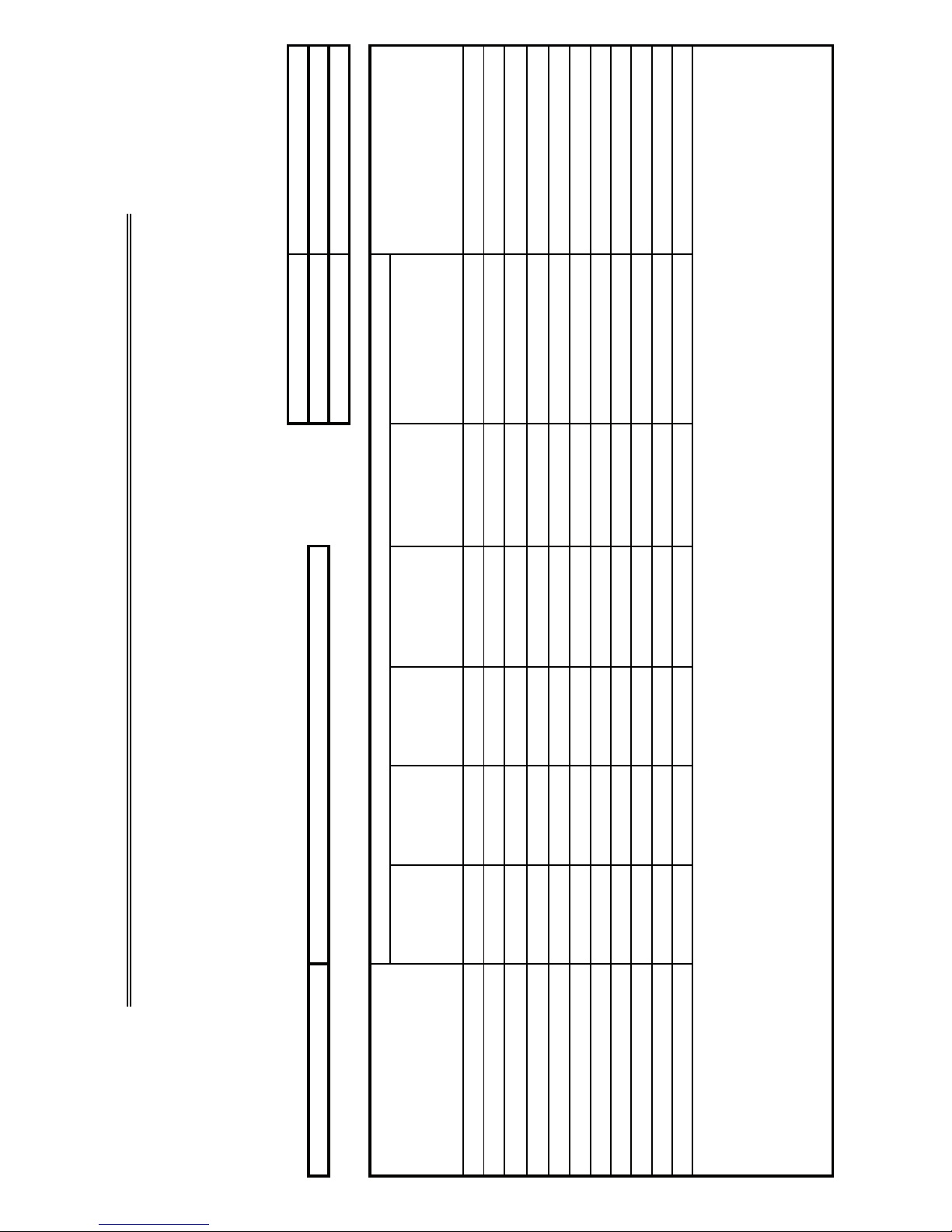

TABLE OF CONTENTS

Pg.6

Pg.6

Pg.6

Pg.6

Pg.6

Pg.6

Pg.7

Pg.7

Pg.7

Pg.7

Pg.7

Pg.8

Pg.8

Pg.8

Pg.8

Pg.8

Pg.8

Pg.8

Pg.9

Pg.9

Pg.9

Pg.9

Pg.9

Pg.9

Pg.10

Pg.10

Pg.10

Pg.10

Pg.10

Pg.10

Pg.11

Pg.12

Pg.13

Pg.13

Pg.13

Pg.13

Pg.13

Pg.13

Pg.14

Pg.14

Pg.14

Pg.14

Pg.15

Pg.15

Pg.15

Pg.15

Pg.16

Pg.16

Pg.16

Pg.17

Pg.17

Pg.17

Pg.17

Pg.18

Pg.18

Pg.18

Pg.1

Pg.2

Pg.4