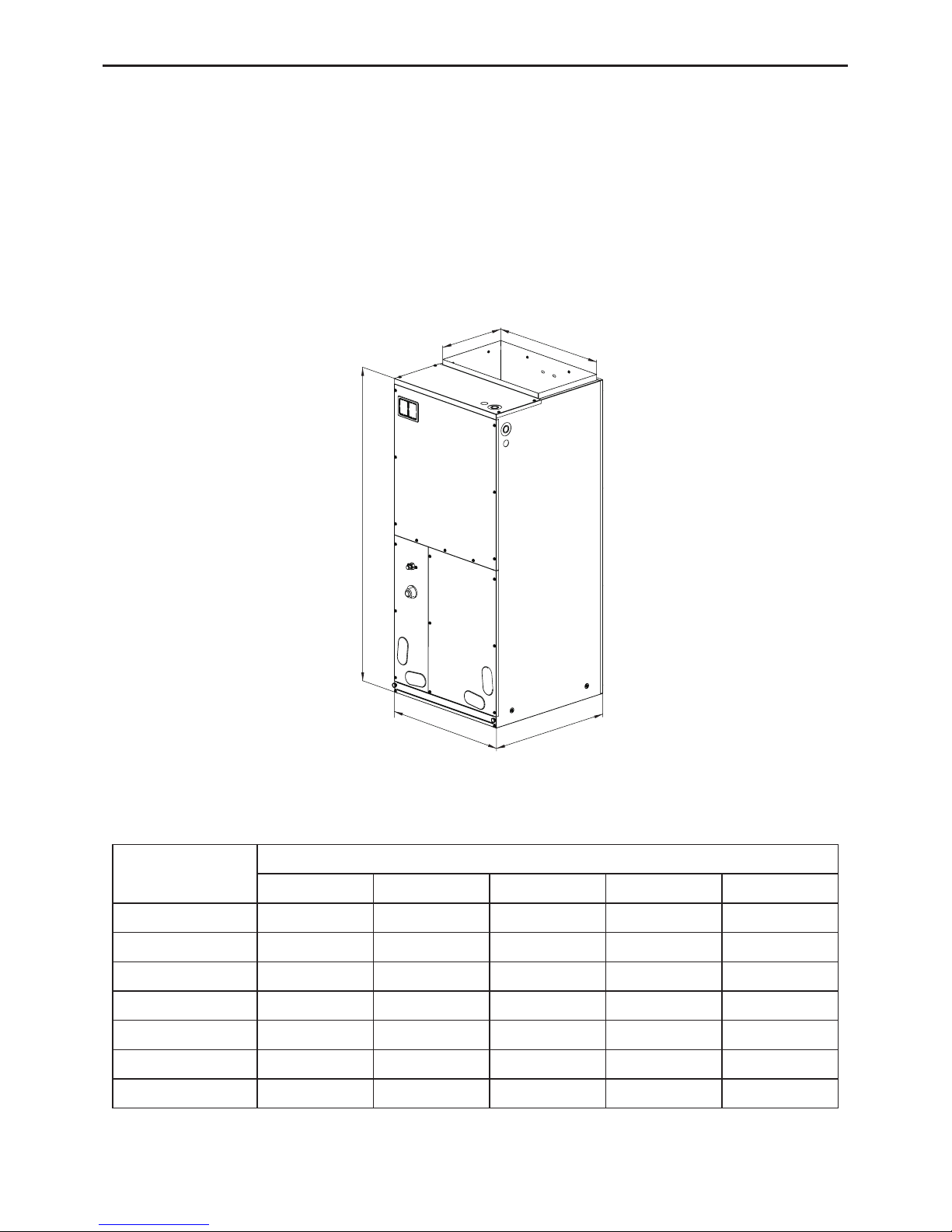

Air Handler

5

3. Preparative for Installation

3.1 Pre-Installation Instruction

3.1.1 Checking Product Received

After receiving the product, please check if there is any damage caused by transportation.

Shipping damage is the responsibility of the carrier. Verify the model number, specications and

accessories are correct prior to installation. The distributor or manufacturer will not accept claims

from dealers for transportation damage or installation of incorrectly shipped units.

3.1.2 Before Installation

Carefully read all instructions for the installation prior to installing product. Make sure each step

or procedure is understood and any special considerations are taken into account before starting

installation. Assemble all tools, hardware and supplies needed to complete the installation. Some

items may need to be purchased locally. Make sure everything needed to install the product is on

hand before starting.

3.1.3 Codes & Regulations

This product is designed and manufactured to comply with national codes. It is installer’s

responsibilities to install the product in accordance with such codes and/or any prevailing local

codes/regulations. The manufacturer assumes no responsibilities for equipment installed in violation

of any codes or regulations.

3.1.4 Replacement Parts

When reporting shortages or damages, or ordering repair parts, give the complete product

model and serial numbers as stamped on the product. Replacement parts for this product are

available through your contractor or local distributor.

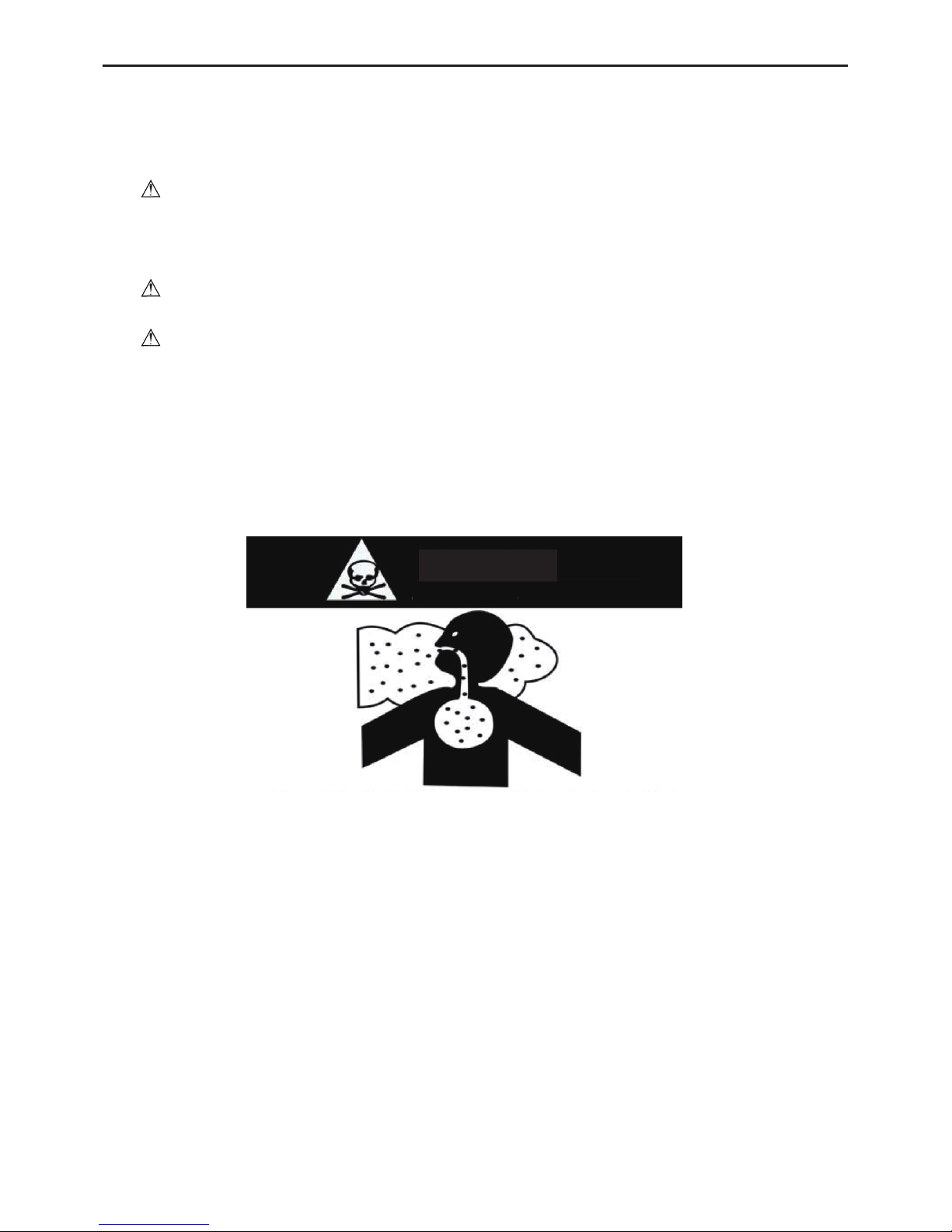

3.2 Important Safety Instructions

Recognize Safety Symbols, Words, and Labels

The following symbols and labels are used throughout this manual to indicate immediate or

potential hazards. It is the owner’s responsibility to read and comply with all safety information and

instructions accompanying these symbols. Failure to heed safety information increases the risk of

serious personal injury or death, property damage and/or product damage.

DANGER: Immediate hazards which will result in property damage, product damage, severe

personal injury or death.

WARNING: Hazards or unsafe pratices could result in property damage, product damage,

severe personal injury or death.

CAUTION: Hazards or unsafe practices which may result in property damage, product

damage, severe personal injury or death.

WARNING: Before serving or installing this equipment. The electrical power to this unit

must be in the “off ” position. Caution, more than one disconnect may exist. Failure to observe this

warning may result in an electrical shock that can cause personal injury or death.

WARNING: The united states environmental protection agency (‘epa”) has issued various

regulations regarding the introduction and disposal of refrigerants introduced into this unit. Failure