WARNING GENIE Z45/25 BOOM LIFT “MEWP”

Any piece of equipment can be dangerous if not operated properly. YOU are responsible for the safe operation of this equipment. The operator must carefully read and

follow any warnings, safety signs and instructions provided with or located on the equipment. Do not remove, defeat, deface or render inoperable any of the safety

devices or warnings on this equipment. If any safety devices or warnings have been removed, defeated, defaced or rendered inoperable, DO NOT USE THIS

EQUIPMENT!!! This Page Contains Basic Guidelines & Safety Warnings For This Lift. But It Is Not A Substitute For The Operators Manual. READ THE

OPERATORS MANUAL!

OPERATING INSTRUCTIONS

The Operator’s Manual is located in the black plastic box in the front of the operator’s platform.

Before you operate this lift, read, understand and obey all the safety rules and operating instructions in the Operator’s Manual

Always perform a pre-operation inspection and function test prior to use for every shift as outlined in the Operators Manual!

Warning 4-Wheel Drive Aerial Lifts

Please be aware this 4-Wheel Drive lift will only provide 1-wheel per axle drive over certain driving conditions. Under more severe conditions this could cause the lift

to spin one opposing tire per axle. Caution should be used when driving over unimproved surfaces, gravel roads, rough terrain, or soft and muddy conditions.

Customers are responsible for tow and recovery services should the lift become stuck. A Tool Shed does not provide any tow or recovery services.

TIP OVER HAZARD, this lift is for use on level compacted surfaces only! Warning: Misuse, operating when not level and overloading the platform will cause this

Lift to Rollover. The Equipment Protection Plan does not cover damage from Rollover or to Tires. Renter is responsible for tow and recovery services should the Lift

become stuck or rolled over. A Tool Shed does not provide any tow or recovery services.

WARNING: Only Qualified persons shall operate the equipment, and shall do so in accordance with the full provisions outlined in the operator’s manual provided.

Only lessee’s Qualified operators are authorized to operate the equipment. Do not lend, or sub-lease this equipment.

OSHA LAW REQUIRES A FULL BODY HARNESS WITH LANYARD ATTACHED TO THE LANYARD ANCHORAGE BE WORN AT ALL TIMES BY

EVERY PERSON IN THE PLATFORM! Never Move The Lanyard From One Anchorage Point To Another Unless The Platform Is On The Ground And The

Engine Is Off!

$100.00 PER HOUR TO REMOVE PAINT, PLASTER, ETC.

IMPORTANT SAFETY RULES TO FOLLOW

1. Do not raise or extend the boom unless the machine is on a firm level surface.

2. This machine is not electrically insulated and will not provide protection from contact with electrical current Maintain a safe distance from any power lines!

3. Do not use the machine as a ground for welding.

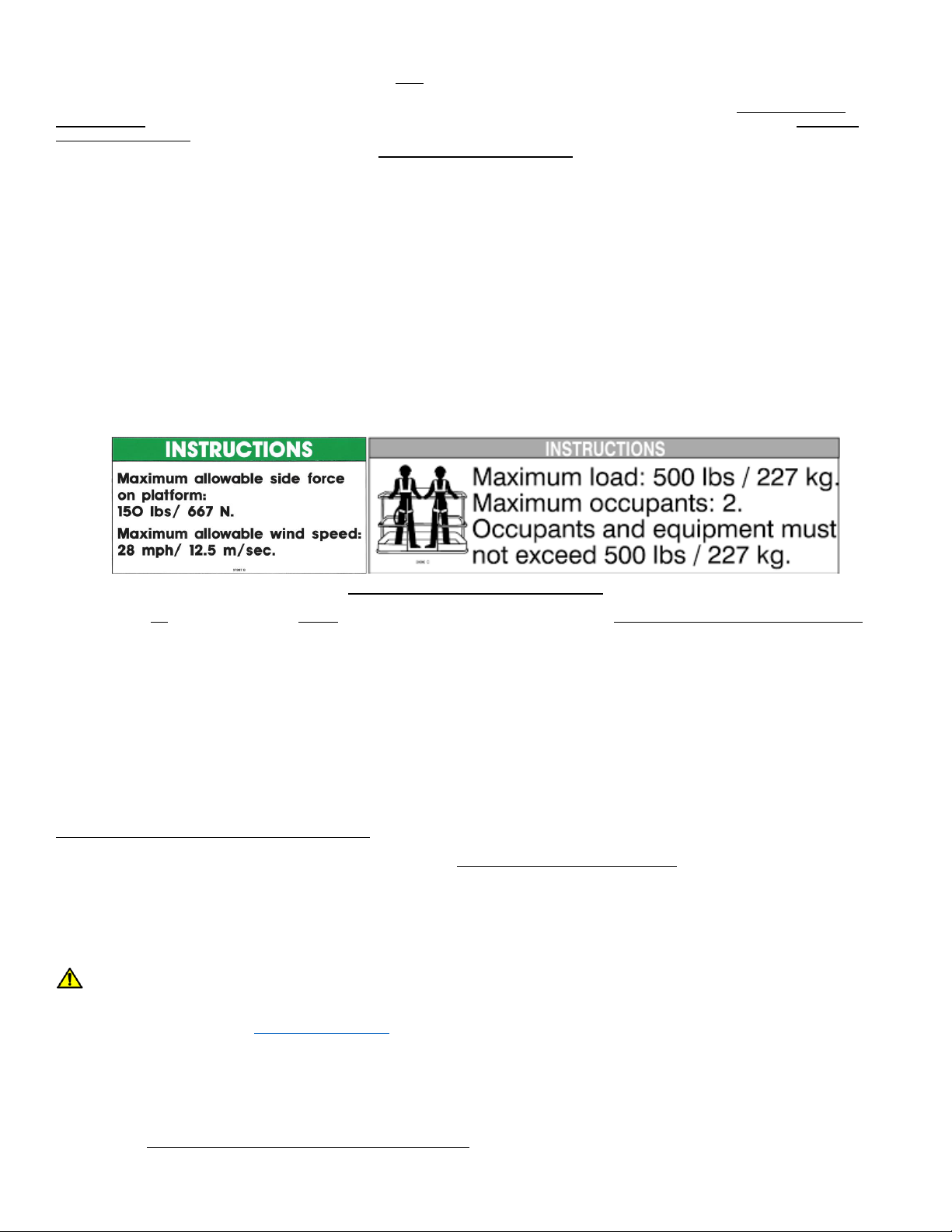

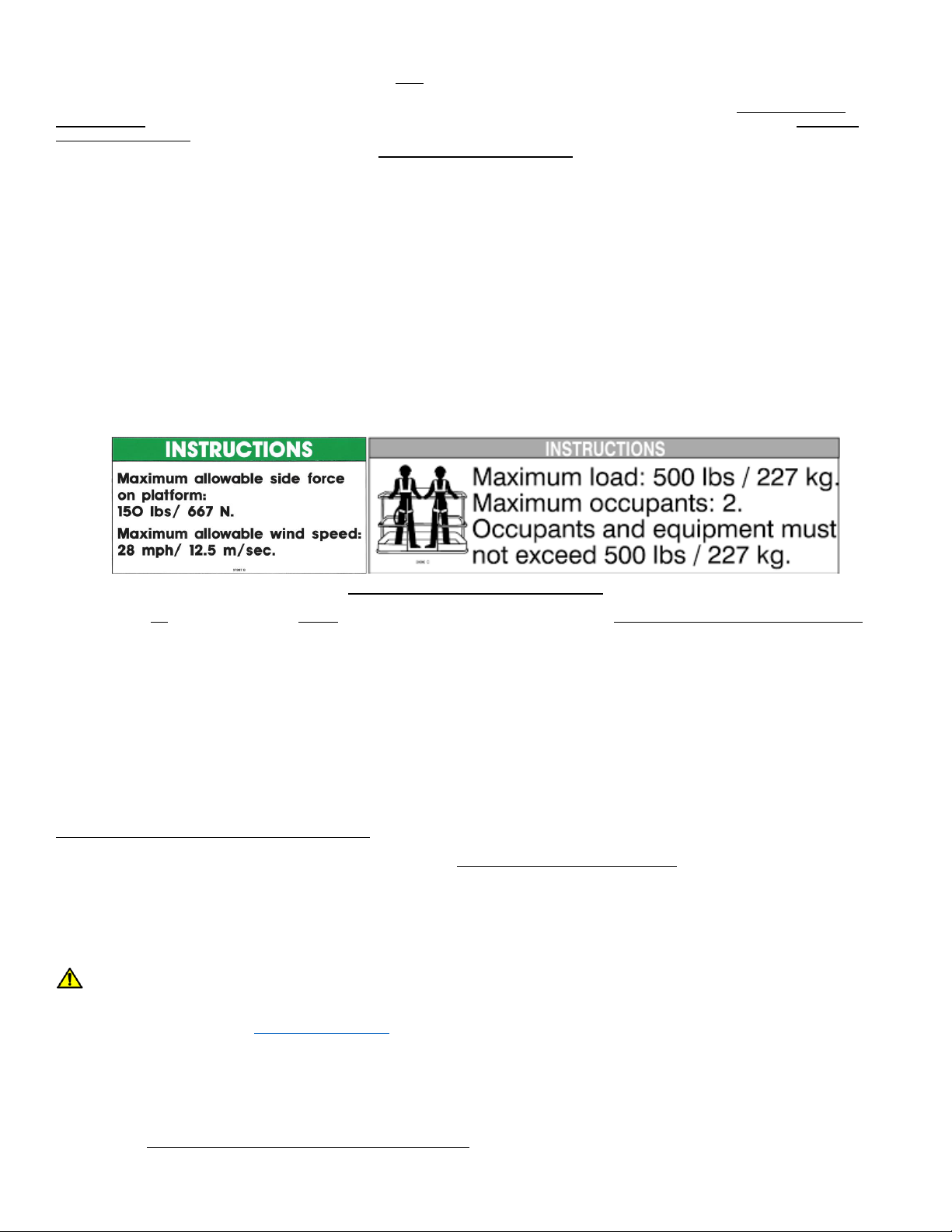

4. Do not raise the boom in strong or gusty winds.

5. Do not drive the machine on or near uneven terrain, unstable surfaces or other hazardous conditions with the boom raised or extended.

6. Do not push off or pull toward any object outside the platform.

7. Do not place or attach overhanging loads to any part of this machine.

8. Do not place ladders or scaffolds in platform or against any part of this machine.

9. Never sit, stand or climb on the guardrails. Both feet must always be on the platform!

10. Do not use machine on a moving or mobile surface or trailer or vehicle.

Warning metal conducts electricity. Do Not use this Lift where it may come into contact with power lines or other electric circuts. Failure to comply to this

warning will result in serious personal injury or death. For appropriate distances from High Voltage lines see chart below.

Maintain safe distances away from electrical power lines and apparatus in accordance with applicable governmental regulations and the following chart

Voltage Minimum Safe Approachable Distance

Phase to Phase Feet Meters THIS LIFT MAY REQUIRE DIESEL FUEL

0 to 300V Avoid Contact GAS OR PROPANE

300V to 50KV 10 3.1 ALWAYS CHECK BEFORE YOU FILL

50KV to 200KV 15 4.6

200KV to 350KV 20 6.1

350KV to 500KV 25 7.6 Lift Functions Will Not Operate With The Generator Engaged!

500KV to 750KV 35 10.7

750KV to 1000KV 45 13.7

Allow for mast movement and electrical line sway or sag, and be aware of strong or gusty winds. Do not use the machine as a ground for welding.

WARNING: Operating, servicing and maintaining this equipment can expose you to chemicals including engine exhaust, carbon monoxide and lead, which are

known to the State of California to cause cancer and birth defects or other reproductive harm. To minimize your exposure, avoid breathing exhaust, do not idle the

engine except as necessary, operate and service your equipment in a well-ventilated area and wear gloves or wash your hands frequently when servicing your

equipment. For more information go to www.P65warnings.ca.gov

This equipment is subject to Section 2449 (d)(3) California Code of Regulations (A) Idling Limit - No vehicle or engines subject to this regulation may idle for

more than 5 consecutive minutes. Idling of a vehicle that is owned by a rental company is the responsibility of the renter or lessee, and the rental agreement should so

indicate. The idling limit does not apply to: 1. idling when queuing, 2. idling to verify that the vehicle is in safe operating condition, 3. idling for testing,

servicing, repairing or diagnostic purposes, 4. idling necessary to accomplish work for which the vehicle was designed (such as operating a crane),

5. idling required to bring the machine system to operating temperature, and 6. idling necessary to ensure safe operation of the vehicle.

If the person receiving this handout will not be the user of the equipment, forward these instructions to the operator. If there is any doubt as to the operation or safety

of the equipment, DO NOT USE!!! CALL A TOOL SHED IMMEDIATELY!!! FAILURE TO FOLLOW THESE INSTRUCTIONS COULD RESULT IN

INJURY OR DEATH!