PartNo.97550 GenieSuperliftAdvantage 5

Operator's ManualThird Edition • Third Printing

SAFETY RULES

Damaged Machine Hazards

Donot use a damaged or

malfunctioningmachine.

Do not use a machine with a

worn,frayed,kinkedordamaged

cable.

Do not use a machine with less

than 4 wraps of cable on the

winchdrumwhen the carriageis

fullylowered.

Conductathorough

pre-operationinspectionpriorto

each use.

Be sure all decals are in place and legible. See

Decals section.

Be sure that the operator's manual is complete,

legible and in the storage container located on the

machine.

Maintainproperlubricationon thewinch.See

Genie

Superlift Parts and Service Manual

for details. Do

not allow oil or grease on braking surfaces.

Do not use any type of lubrication on the column

surfaces.

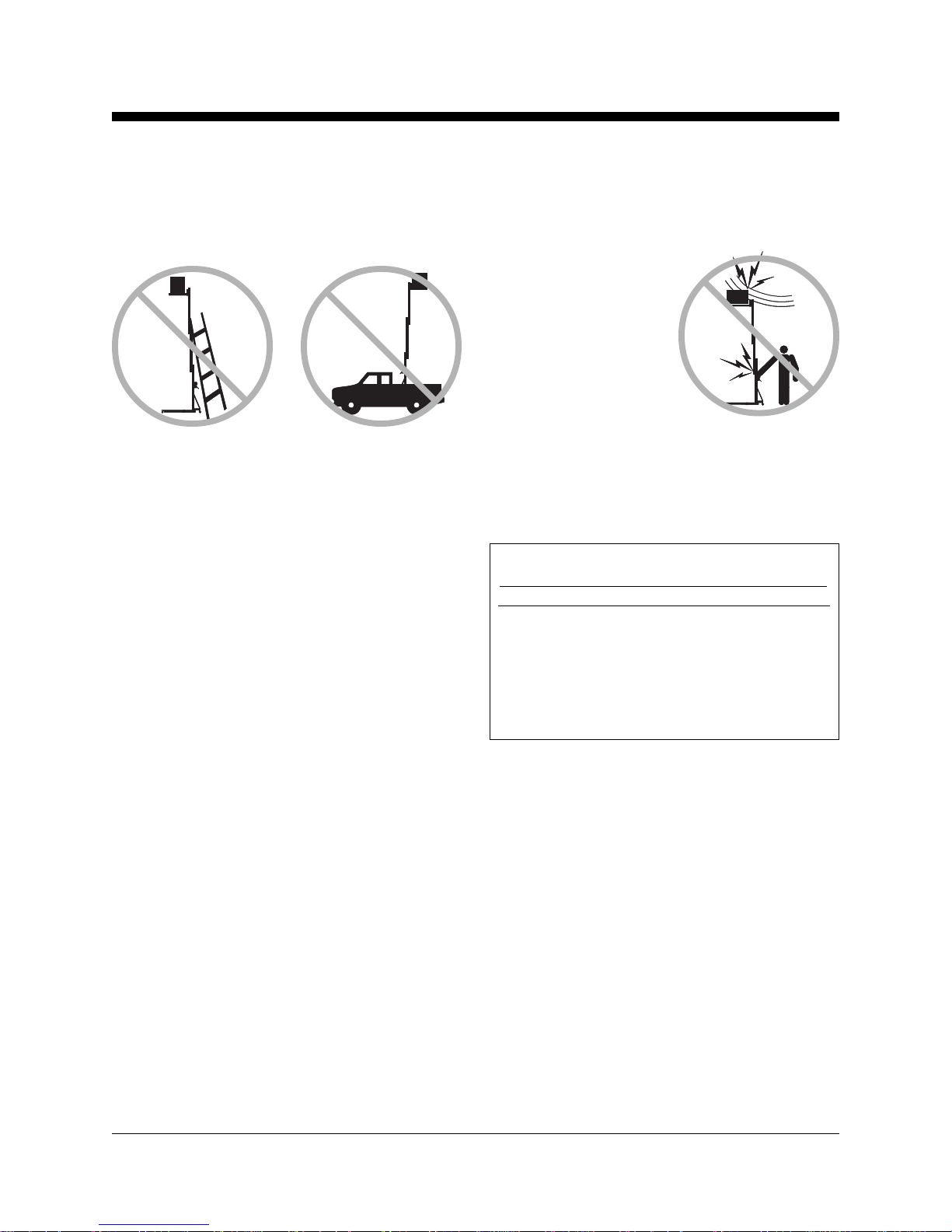

Improper Use Hazard

Neverleavea Genie Superlift unattended with a

load.Unauthorizedpersonnelmayattemptto

operatethemachinewithoutproperinstruction,

creatinganunsafecondition.

Decal Legend

Genie product decals use symbols, color coding

and signal words to identify the following:

Safety alert symbol—used to alert

personneltopotentialpersonal

injury hazards. Obey all safety

messages that follow this symbol

to avoid possible injury or death.

Red—usedto indicatethe

presence of an imminently

hazardous situation which, if not

avoided, will result in death or

seriousinjury.

Orange—usedtoindicatethe

presence of a potentially

hazardous situation which, if not

avoided, could result in death or

seriousinjury.

Yellow with safety alert symbol—

used to indicate the presence of a

potentiallyhazardoussituation

which, if not avoided, may cause

minorormoderateinjury.

Yellow without safety alert

symbol—used to indicate the

presence of a potentially

hazardous situation which, if not

avoided, may result in property

damage.

Green—usedtoindicateoperation

ormaintenanceinformation.