FIGURES

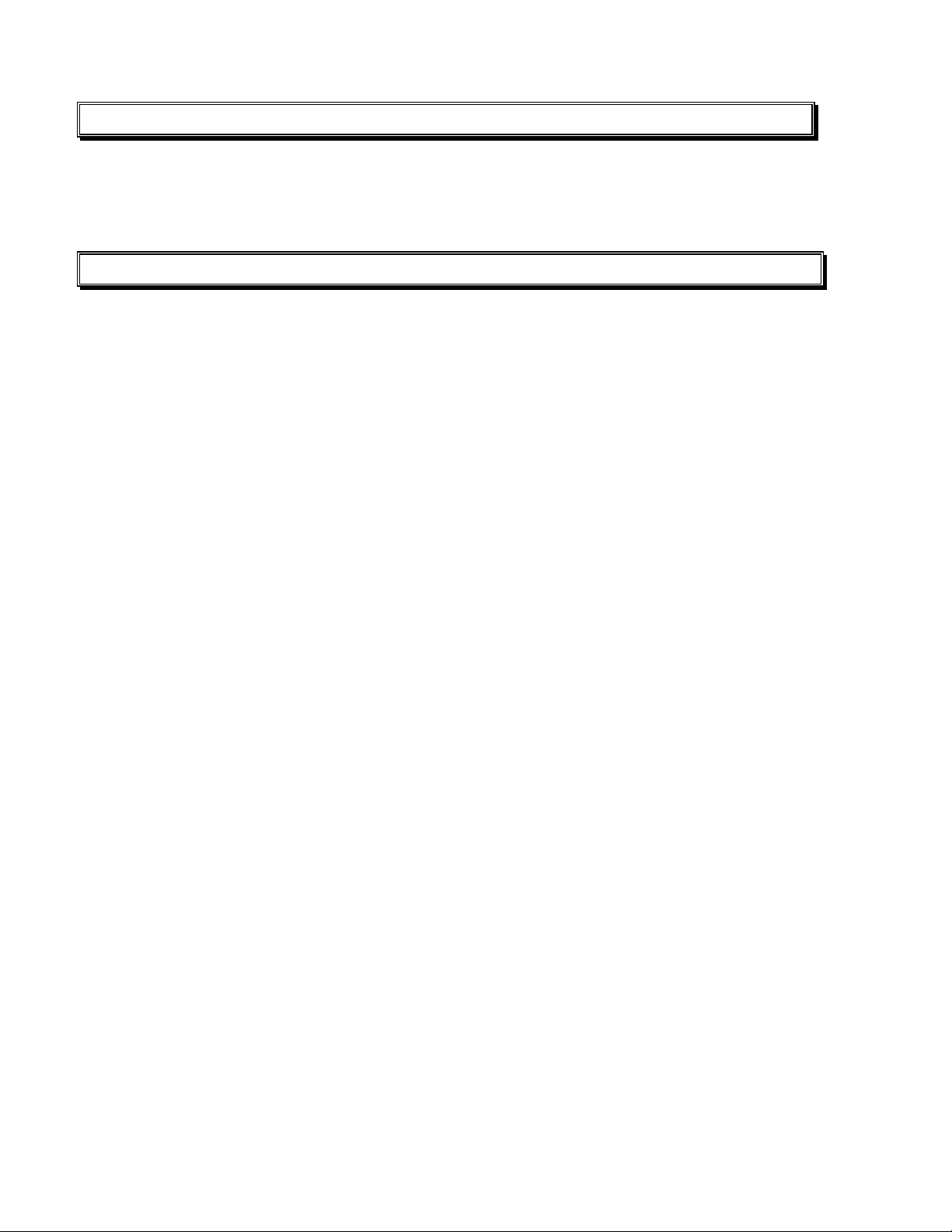

FIGURE 1-EXTRACTING THE 8020-59 INSTALLER .........................................................................................................2

FIGURE 2-SELECT DESTINATION FOLDER .....................................................................................................................2

FIGURE 3-EXTRACTED 8020-59 INSTALLER .................................................................................................................3

FIGURE 4-INSTALL WIZARD,START SCREEN................................................................................................................3

FIGURE 5-INSTALL WIZARD,CHOOSE USERS ...............................................................................................................3

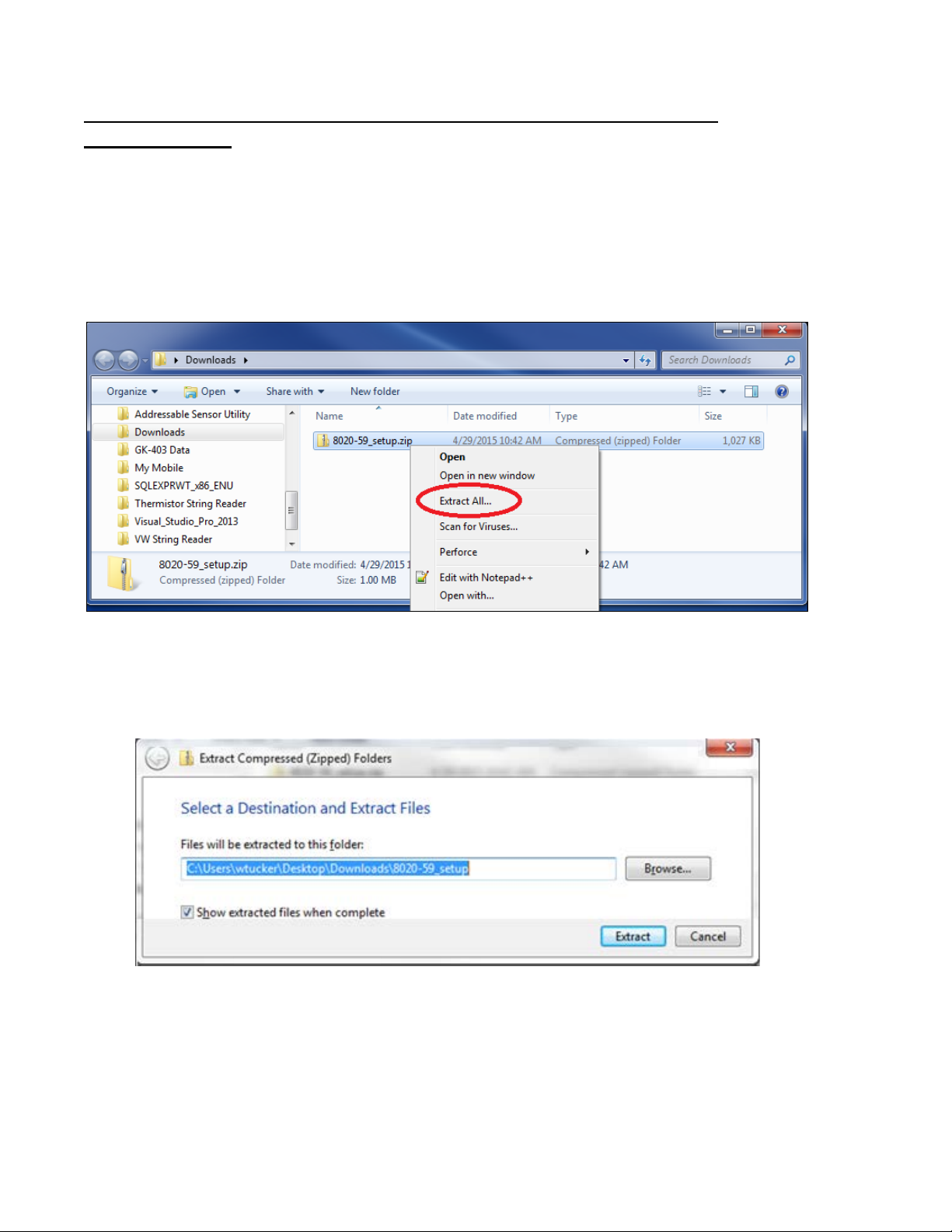

FIGURE 6-INSTALL WIZARD,CHOOSE START MENU FOLDER.......................................................................................4

FIGURE 7-INSTALL WIZARD,INSTALLATION COMPLETE ..............................................................................................4

FIGURE 8-INSTALL WIZARD,LAUNCH 8020-59 APPLICATION......................................................................................5

FIGURE 9-8020-59 SOFTWARE APPLICATION,STARTUP DIALOG..................................................................................5

FIGURE 10 -COMMUNICATIONS PARAMETERS DIALOG .................................................................................................6

FIGURE 11 -SINGLE CHANNEL CONFIGURATION SCREEN ..............................................................................................8

FIGURE 12 -SINGLE CHANNEL MONITOR.......................................................................................................................8

FIGURE 13 -CONTROL SIGNAL SEQUENCE:SINGLE CHANNEL MODE ..........................................................................11

FIGURE 14 -CONTROL SIGNAL SEQUENCE:16-CHANNEL MODE (CHANNELS ONE AND TWO ONLY) ..........................12

FIGURE 15 -CONTROL SIGNAL SEQUENCE:32-CHANNEL MODE (CHANNELS ONE THROUGH FOUR ONLY) ................13

FIGURE 16 -COMMUNICATION TIMEOUT WARNING MESSAGE ....................................................................................20

FIGURE 17 -16-CHANNEL CONFIGURATION SCREEN ...................................................................................................22

FIGURE 18 -16-CHANNEL MONITOR SCREEN...............................................................................................................23

FIGURE 19 -CHANNEL ONE MONITOR .........................................................................................................................24

FIGURE 20 -32-CHANNEL MONITOR SCREEN...............................................................................................................25

FIGURE 21 -CHANNEL THREE MONITOR......................................................................................................................25

FIGURE 22 -16-CHANNEL MULTIPLEXER TIMING REQUIREMENTS ..............................................................................27

FIGURE 23 -32-CHANNEL MULTIPLEXER TIMING REQUIREMENTS ..............................................................................27

FIGURE 24 -CONNECTION EXAMPLE FOR ONE CHANNEL 8020-59 WITH VOLTAGE OUTPUT TO DIGITAL I/O DAS.....29

FIGURE 25 -CONNECTION EXAMPLE FOR 16-CHANNEL MULTIPLEXER,8020-59 WITH VOLTAGE OUTPUT AND DIGITAL

I/O DAS .............................................................................................................................................................30

FIGURE 26 -CONNECTION EXAMPLE FOR 32-CHANNEL MULTIPLEXER,8020-59 WITH VOLTAGE OUTPUT AND DIGITAL

I/O DAS .............................................................................................................................................................31

FIGURE 27 -CONNECTION EXAMPLE FOR ONE CHANNEL 8020-59 WITH CURRENT OUTPUT TO DIGITAL I/O DAS .....32

FIGURE 28 -CONNECTION EXAMPLE FOR 16-CHANNEL MULTIPLEXER,8020-59 WITH CURRENT OUTPUT AND DIGITAL

I/O DAS .............................................................................................................................................................33

FIGURE 29 -CONNECTION EXAMPLE FOR 32-CHANNEL MULTIPLEXER,8020-59 WITH CURRENT OUTPUT AND DIGITAL

I/O DAS .............................................................................................................................................................34

FIGURE 30 -CONNECTION EXAMPLE FOR ONE CHANNEL.8020-59 WITH VOLTAGE OUTPUT,8020-59 PLC AND PLC

DAS ...................................................................................................................................................................35

FIGURE 31 -CONNECTION EXAMPLE FOR 16-CHANNEL MULTIPLEXER,8020-59 W/VOLTAGE OUTPUT,8020-59 PLC

AND PLC DAS....................................................................................................................................................36

FIGURE 32 -CONNECTION EXAMPLE FOR 32-CHANNEL MULTIPLEXER,8020-59 W/VOLTAGE OUTPUT,8020-59 PLC

AND PLC DAS....................................................................................................................................................37

FIGURE 33 -CONNECTION EXAMPLE FOR ONE CHANNEL 8020-59 WITH CURRENT OUTPUT,8020-59 PLC AND PLC

DAS ...................................................................................................................................................................38

FIGURE 34 -CONNECTION EXAMPLE FOR 16-CHANNEL MULTIPLEXER,8020-59 W/CURRENT OUTPUT,8020-59 PLC

AND PLC DAS....................................................................................................................................................39

FIGURE 35 -CONNECTION EXAMPLE FOR 32-CHANNEL MULTIPLEXER,8020-59 W/CURRENT OUTPUT,8020-59 PLC

AND PLC DAS....................................................................................................................................................40

FIGURE 36 -VIBRATING WIRE PRESSURE TRANSDUCER CALIBRATION REPORT..........................................................44