EM31-SH MANUAL Page 1

1.0 INTRODUCTION

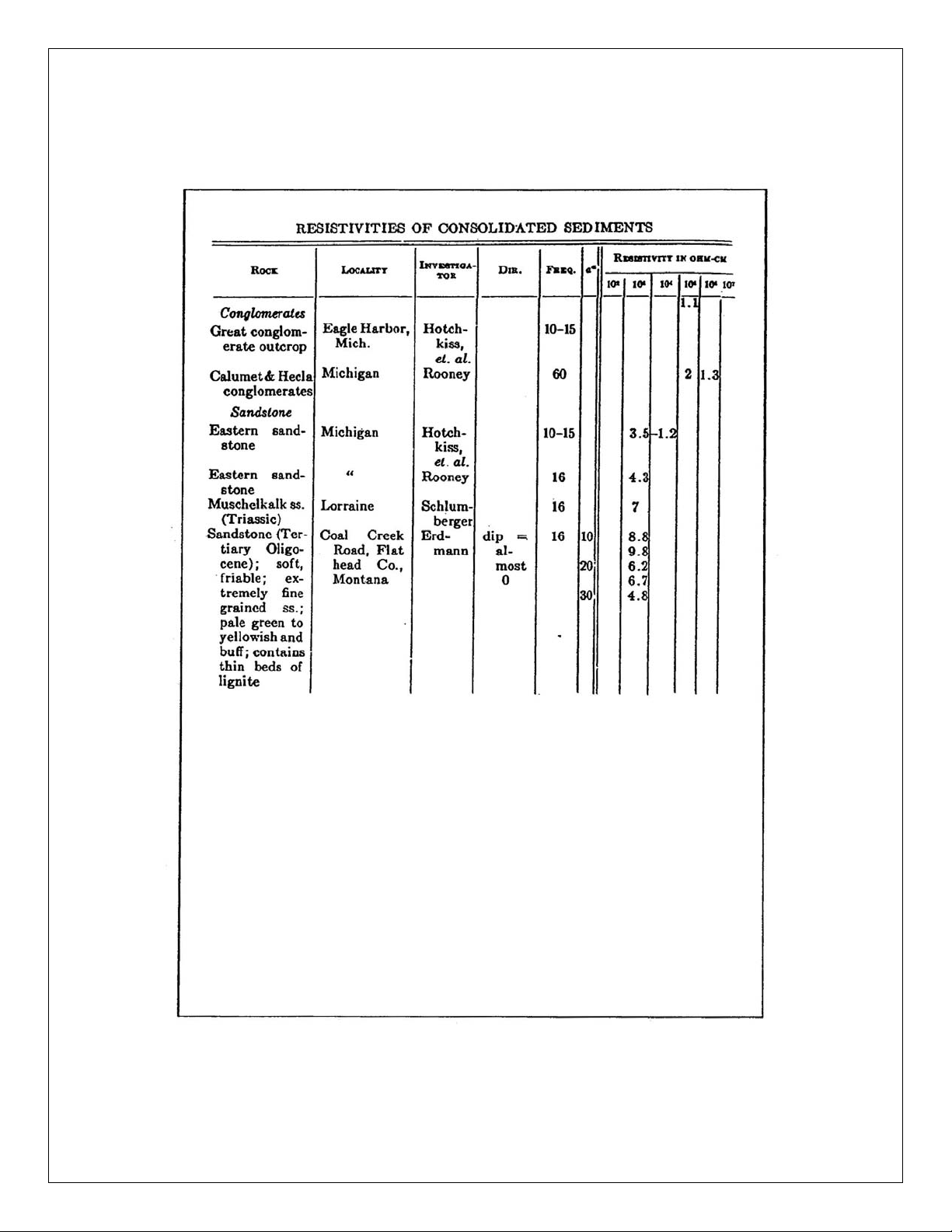

Measurement of ground resistivity is one of the oldest

geophysical techniques. Table 1, taken directly from

Heiland*, lists typical values of resistivity for a variety

of geological materials (pages 4-8). The values given are in

ohm-centimeters and must be divided by one hundred to give

ohm-meters.

It will be observed that in most cases the actual resistivity

itself is not diagnostic and a knowledge of the way in which

the resistivity varies laterally and with depth is of great

importance, since this permits us to “see” features as a

result of their shape rather than their actual resistivity

values. There is thus a requirement for instrumentation which

permits the rapid and accurate measurement of terrain

resisitivity. Since the EM31 does not require electrical

contact with the ground it fulfils this objective.

The basic principle of operation of EM31 is simple. With

reference to Figure 1 a transmitter coil located at one end

of the instrument induces circular eddy current loops in the

earth. Under certain conditions fulfilled in the design of

the EM31 the magnitude of any one of these current loops is

directly proportional to the terrain conductivity in the

vicinity of that loop. Each one of the current loops

generates a magnetic field which is proportional to the value

of the current flowing within that loop. A part of the

magnetic field from each loop is intercepted by the receiver

coil and results in an output voltage which is therefore also

linearly related to the terrain conductivity.

* Heiland, C.A. Geophysical Exploration. Hafner Publishing Co., New York 1968