Page 9

776 M0 01 C 24-04-2014

Set Offset

In the sub menu “Set Offset” it is possible to set the actual offset of the flowmeter. This function should just be used when the

BAMOFLONIC is completely filled with liquid and there is no flow. A small offset change e.g. caused by variable temperatures is

automatically done by the flow

Language

The language of the display can be changed. Available languages are English and erman.

Filter

The function ”Filter“ averages the analog output signal.

Possible settings: Soft, edium, Strong, Off

The analog output signal reacts faster to signal changes when average determination is soft.

Whereas the output signal reacts slower when average determination is strong.

Units

The BAMOFLONIC is able to show actual flow or the volume in different units.

Following units can be selected: ml/s + l, al/min + al , l/min + l, l/min + m³.

The first letters correspond the unit of the flow value. The letters after the + correspond the unit of the volume value.

Reset Counter

The volume counter of BAMOFLONIC can be reset.

Note, accidentally erased counter values are permanently lost. After reset the counter works normally.

Basic Trim

This function insures that the flowmeter is conforming to the media specific characteristics. By executing this function the

BAMOFLONIC runs a self-diagnostic function which optimizes all important parameters. This process lasts approximately 1

minute.

To make sure the basic trim is correctly done the flowmeter has to be filled with liquid without a flow.

When there is an error detected while performing the basic trim function, the display shows “Error”. After successfully finishing

the basic trim, the display shows “Done”.

Creeping suppression

The creeping suppression excludes flow measurements that result from convection in a narrow band around zero, even with a

closed valve. At the factory, the creeping suppression is set at a standard value in relation to the cross-section of the flowmeter.

Diagnostic

The sub menu “Diagnostic“ shows the software/hardware version and other helpful values for analysis.

Knowing about the actual values or the instrument´s present status makes it easy to review the

measurement by the manufacturer.

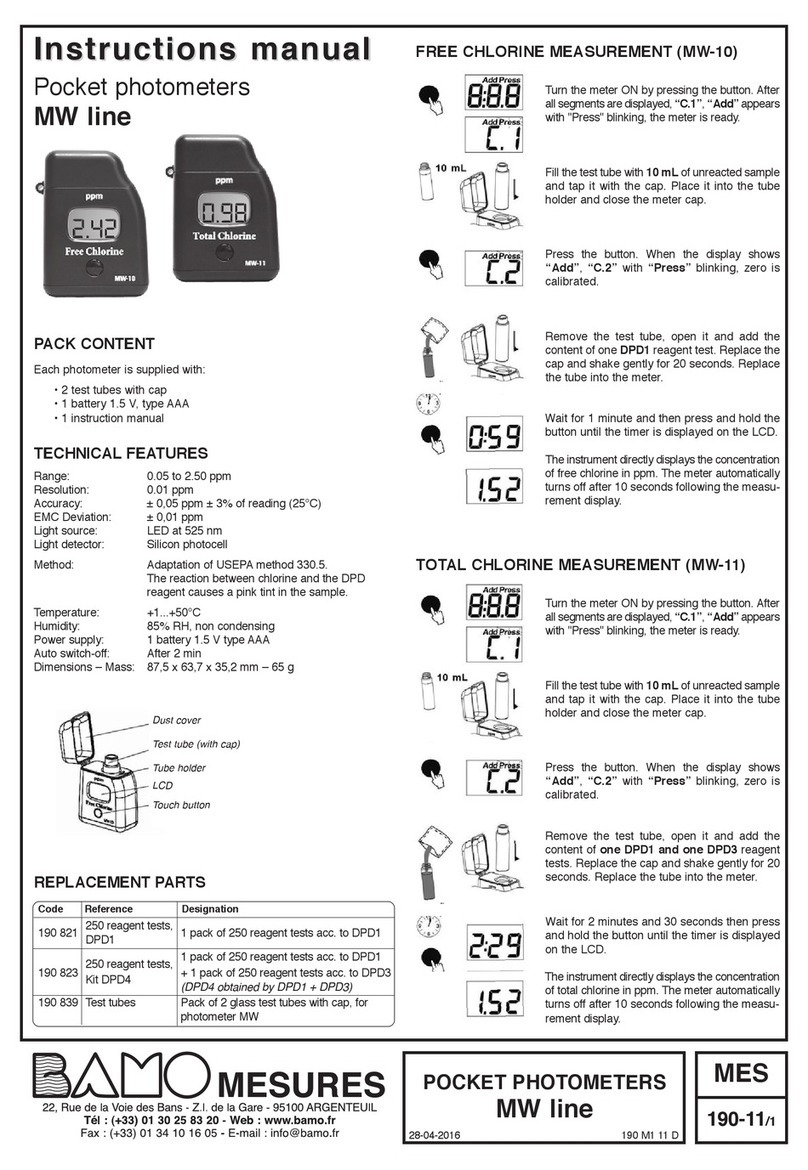

Flow [l/min]

Pulse/Analog output

The creeping suppression works with a hystere-

sis of - 25%.

Example:

Creeping suppression = 0.6 l/min If the flow rate

is lower than 0.45 l/min the pulse output/analog

output becomes inactive. If the flow rate exceeds

0.6 l/min a pulse is output again and added to the

totalizer. Similarly, a value is transmitted to the

analog output again.

Plages disponibles:

0.0...20 l/min, in 0.006 l/min steps

Default settings:

0.3 l/min for DN10 / 3/8”

0.9 l/min for DN15 / 1/2"

3.5 l/min for DN20 / 3/4”

5.0 l/min for DN25 / 1”

NOTICE

Fig. 10: Function of the creeping suppression (illustrated with 0.6 l/min)