Signet 2552 Metal Magmeter

*3-2552.090*

3-2552.090 Rev E 07/10 English

English

SAFETY INSTRUCTIONS

1. Depressurize and vent systems without Hot-tap valve prior to installation or removal.

2. Confirm chemical compatibility before use.

3. Do not exceed maximum temperature/pressure specifications.

4. Wear safety goggles or face shield during installation/service.

5. Do not disassemble or alter product construction.

6. Disconnect power before attempting any service or wiring.

2. Specifications

1. Description

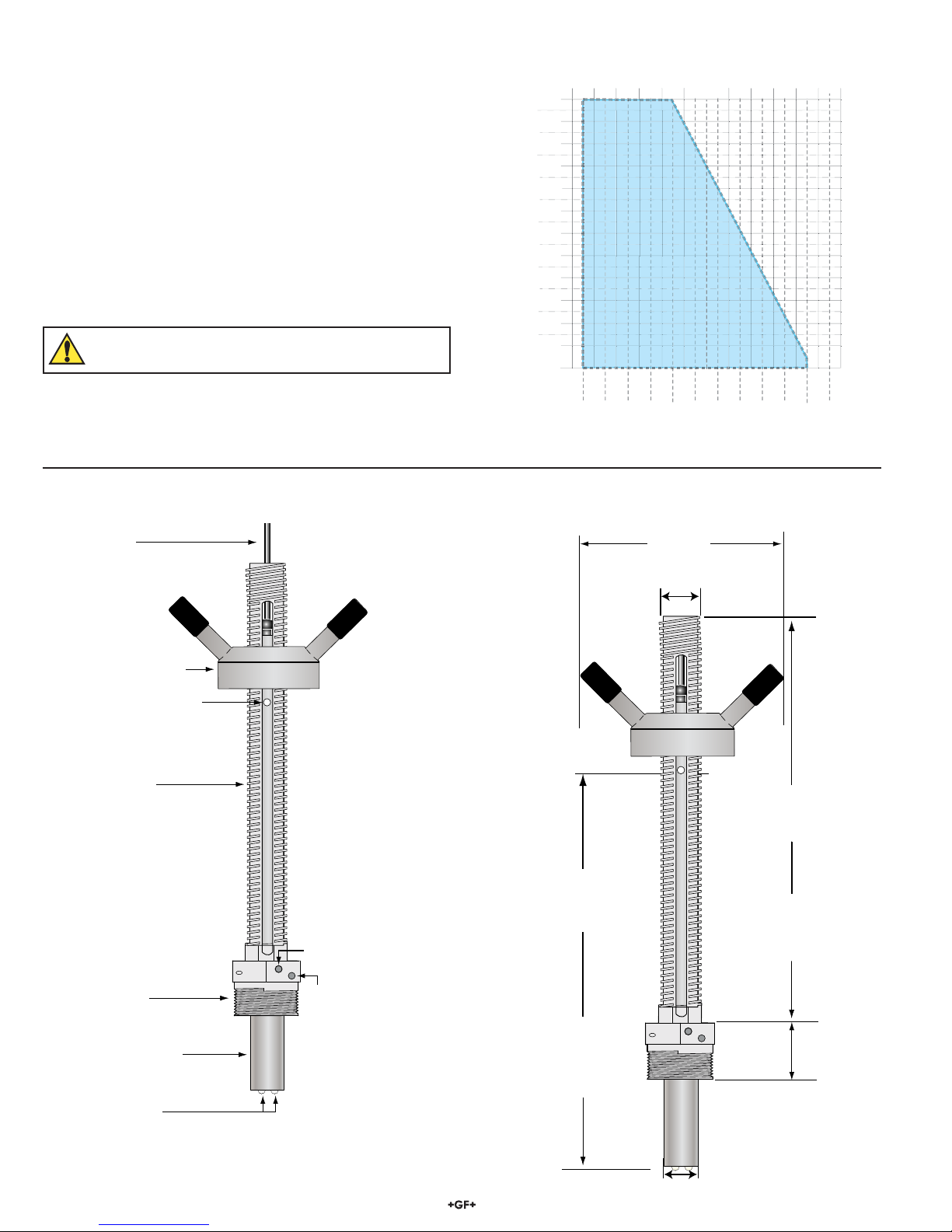

The Signet 2552 Metal Magmeter from Georg Fischer features all-stainless steel construction. The PVDF nosepiece and FPM O-rings

are the only other wetted materials. The 2552 installs quickly into standard 1¼ in. or 1½ in. pipe outlets, and is adjustable to fit pipes

from DN50 to DN2550 (2 to 102 inches). Three sensor lengths allow maximum flexibility to accommodate a variety of hardware

configurations, including ball valves for hot-tap installations.

When equipped with the frequency output, the 2552 is compatible with any Signet flow instrument, while the S3L Digital output enables

multi-channel compatibility with the Signet 8900 Multi-Parameter Flow Controller. Select the blind 4 to 20 mA current output to interface

directly with dataloggers, PLCs or telemetry systems.

Key features include Empty Pipe Detection, LED-assisted troubleshooting, and Bi-Directional span capability (in 4 to 20 mA models).

The Signet 3-0250 USB to Digital (S3L) Configuration/Diagnostic Tool is available to customize every performance feature in the 2552

so it can be adapted to the user's application requirements.

Performance

Pipe size range: DN50 to DN2550 (2 in. to 102 in.)

Flow Range:

• Minimum: 0.05 m/s (0.15 ft/s)

• Maximum: 10 m/s (33 ft/s) for pipes to DN 1200 (48 in.)

3 m/s (10 ft./s) for pipes over DN 1200 (48 in.)

Linearity: ±(1% reading + 0.01 m/s)

±(1% reading + 0.033 ft/s)

Repeatability: ±0.5% of reading @ 25 °C

Accuracy: ±2% of measured value (in reference conditions

where the fluid is water at ambient temperature, the sensor

is inserted at the correct depth and there is a fully developed

flow profile which is in compliance with ISO 7145-1982 (BS

1042 section 2.2))

Minimum Conductivity: 20 S/cm

Wetted Materials

• 316L Stainless Steel body and electrodes

• PVDF Insulator

• O-rings: FPM (standard)

• Cable: 4-cond + shield, PVC jacket (Fixed cable models) or

Water-resistant rubber cable assembly with Turck®NEMA 6P

connector

Power Requirements

• 4 to 20 mA: 24 VDC ± 10%, regulated, 22.1 mA maximum

• Frequency: 5 to 24 VDC ± 10%, regulated, 15 mAmaximum

• Digital (S3L): 5 to 6.5 VDC, 15 mA maximum

• Reverse polarity and short circuit protected

Cable Options

• Fixed 7.6 m (25 ft) cable

• Detachable water tight sensor cable with Turck® connector

sold separately, two lengths: 4m (13 ft) or 6m (19.5 ft)

Custom lengths available, contact Georg Fischer Signet

Electrical

Current Output (4 to 20 mA)

• Programmable and reversible

Factory Range: 4 to 20 mA = 0 to 5 m/s

• Loop Accuracy:

32 A max. error (@ 25 °C @ 24 VDC)

• Temp. drift: ±1 A per °C max.

• Power supply rejection: ±1 A per V

• Isolation: Low voltage < 48 VAC/DC from electrodes and

auxiliary power

• Maximum cable: 300 m (1000 ft)

• Max. Loop Resistance: 300

• Error condition: 22.1 mA

Frequency output

• Compatible with Signet 5075, 5500, 5600, 8550 and 8900

• Max. Pull-up Voltage: 30 VDC

• Short Circuit Protected: 30 V @ 0 pull-up for one hour

• Reverse Polarity Protected to -40 V for 1 hour

• Overvoltage Protected to +40 V for 1 hour

• Max. Current Sink: 50 mA, current limited

• Maximum cable: 300 m (1000 ft)

Digital (S3L) Output

• Compatible with Signet 8900

• Serial ASCII, TTL level 9600 bps

• Maximum cable: Application dependent (See 8900 manual)

Standards and Approvals

• CE

• U.S. Patent No.: 7,055,396 BI

• NEMA 4 (IP65) (fixed cable models)

• NEMA 6P (IP68) (Submersible cable models only)

Signet recommends maximum 3 m. (10 ft) submersion depth

for maximum 10 days continuous submersion.

• Manufactured under ISO 9001 and ISO 14001

China RoHS (Go to www.gfsignet.com for details)