05/23/12 Georgia Amendments-Prescriptive Deck Details Sheet 3 of 22

GENERAL REQUIREMENTS

1. Lumber shall be naturally durable wood or shall be southern pine, grade #2 or better that is pressure-

preservative-treated in accordance with AWPA U1 for the species, product, preservative and end use.

Field cut ends, notches and drilled holes of preservative treated wood shall be treated in the field in

accordance with AWPA M4. Preservative- treated lumber in contact with the ground shall be rated as

“ground-contact.” Please note: not all treated lumber is rated for ground contact.

2. Wood-plastic composites are composed of bound wood and plastic fibers creating material that can be

used as decking and guard elements as permitted herein. Permissible wood-plastic composites must

bear a label indicating its performance criteria and compliance with ASTM D 7032.

3. Nails shall be ring-shanked or annular grooved.

4. Screws and nails shall be hot-dipped galvanized, stainless steel or approved for use with pressure

treated lumber.

5. Hardware, e.g., joist hangers, cast-in-place post anchors, mechanical fasteners, shall be galvanized

with 1.85 oz/sf of zinc (G-185 coating) or shall be stainless steel. Use products such as “Zmax” from

Simpson Strong-Tie or “Triple Zinc” and “Gold Coat” from USP.

6. Electrical receptacles for decks shall comply with the currently approved edition of the National

Electrical Code.

7. Lighting for decks and exterior stairs shall comply with IRC 303.7 Stairway Illumination.

8. Decks constructed in accordance with these details are not approved for privacy screens, planters,

built-in seating or hot tub installations.

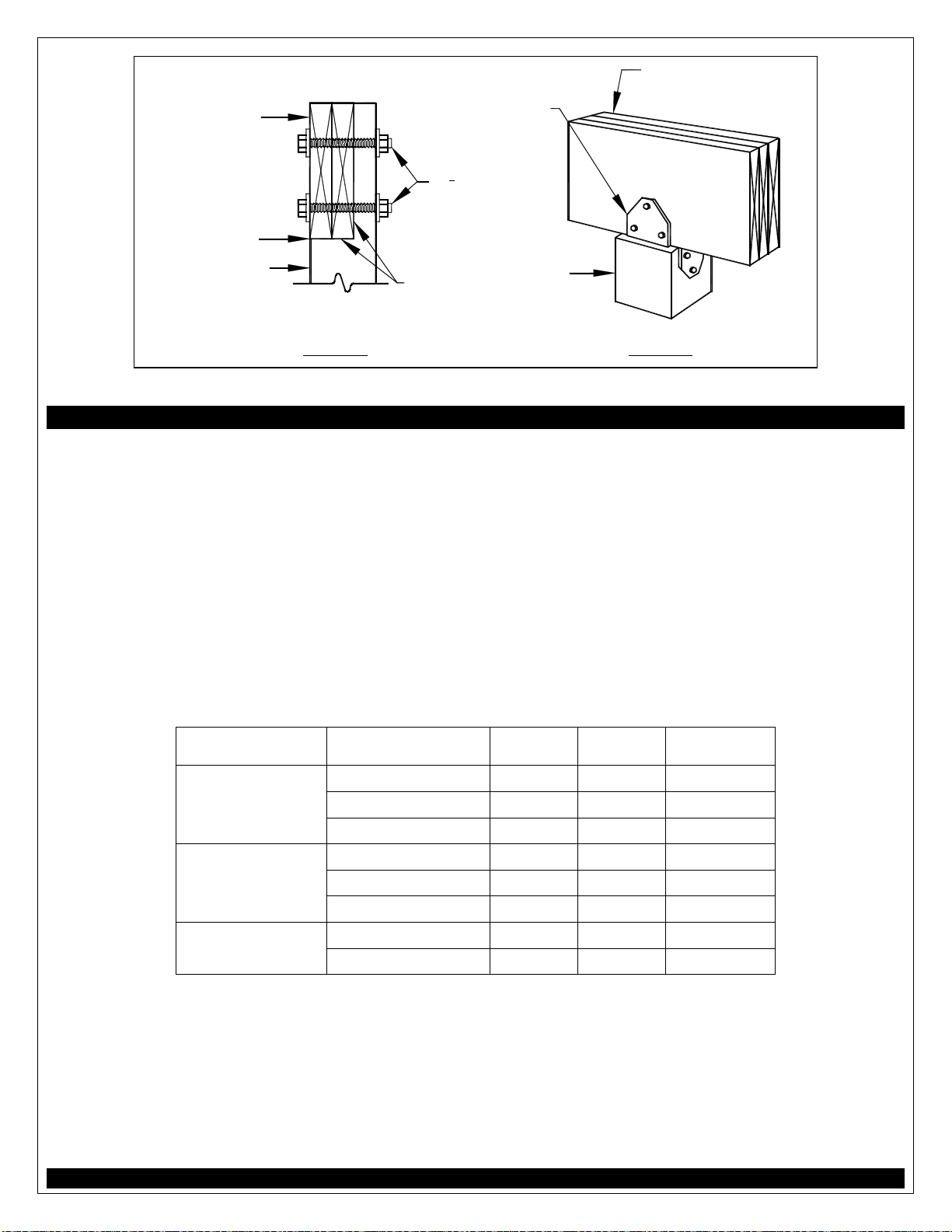

DECKING

Approved Material

Wood and wood-plastic composite decking shall be

installed in accordance with the requirements below.

•Dimensions shall be 2x6 or 5/4("five-

quarter") for wood and per manufacturer for

wood-plastic composites.

•Wood decking may be placed at an angle of

45 to 90 degrees to the joists.

•Attach wood decking in accordance with

FIGURE 1.

•Placement and attachment of wood-plastic

composites shall be per manufacturer's

instructions.

(2)8d nails or (2)#8

screws at each joist

1

8

" typical gap

wood 2x6 or 5/4

("five quarter")

board

FIGURE 1: TYPICAL DECKING

•Wood-plastic composite label and manufacturer's instructions must be left on the jobsite for

inspector verification.

Plastic Decking

Plastic or PVC decking, not considered a wood-plastic composite, may be substituted only when the

product has a valid evaluation report from an accredited listing agency and is capable of resisting a live

load of 40 PSF. Installation shall be in conformance to the evaluation report and the manufacturer's

installation instructions which must be available to the inspector.