3

Contents

1.0 General safety precautions ..................3

1.1 Danger..................................3

1.2 Field of application. . . . . . . . . . . . . . . . . . . . . . . . . 3

1.3 Handling ................................3

1.4 Technical data ............................3

1.5 Construction – table of dimensions ............5

2.0 Installation ...............................5

2.1 Optional equipment ........................7

2.2 Connection ..............................7

2.3 Trial run – exact adjustment .................7

3.0 User instruction – application ................7

4.0 Maintenance .............................8

5.0 Liability. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 8

6.0 Declaration of conformity...................10

1.0 General safety precautions

IMPORTANT – Please study all the instructions before

mounting and commissioning.

Please keep these instructions in a safe place and in-

struct all users in the function and operation of the pro-

duct.

Exchange of filter/maintenance should only be imple-

mented after studying section 4 thoroughly.

Avoid the dismantling of any factory-mounted parts, sin-

ce it impedes the commissioning of the equipment.

All electrical installations must be carried out by an

authorised electrician.

1.1 Danger

Explosive media – The Extraction Arm is not suitable for

the extraction of aluminium dust, flour, textile dust nor for

sawdust or other media, which are connected with danger

of explosion, without specific approval from Geovent A/S.

Placing the hand between the gas spring and the carry-

ing arm could involve a risk of mutilation.

Boring in the gas spring or other ways of puncturing it is

deadly dangerous.

1.2 Field of application

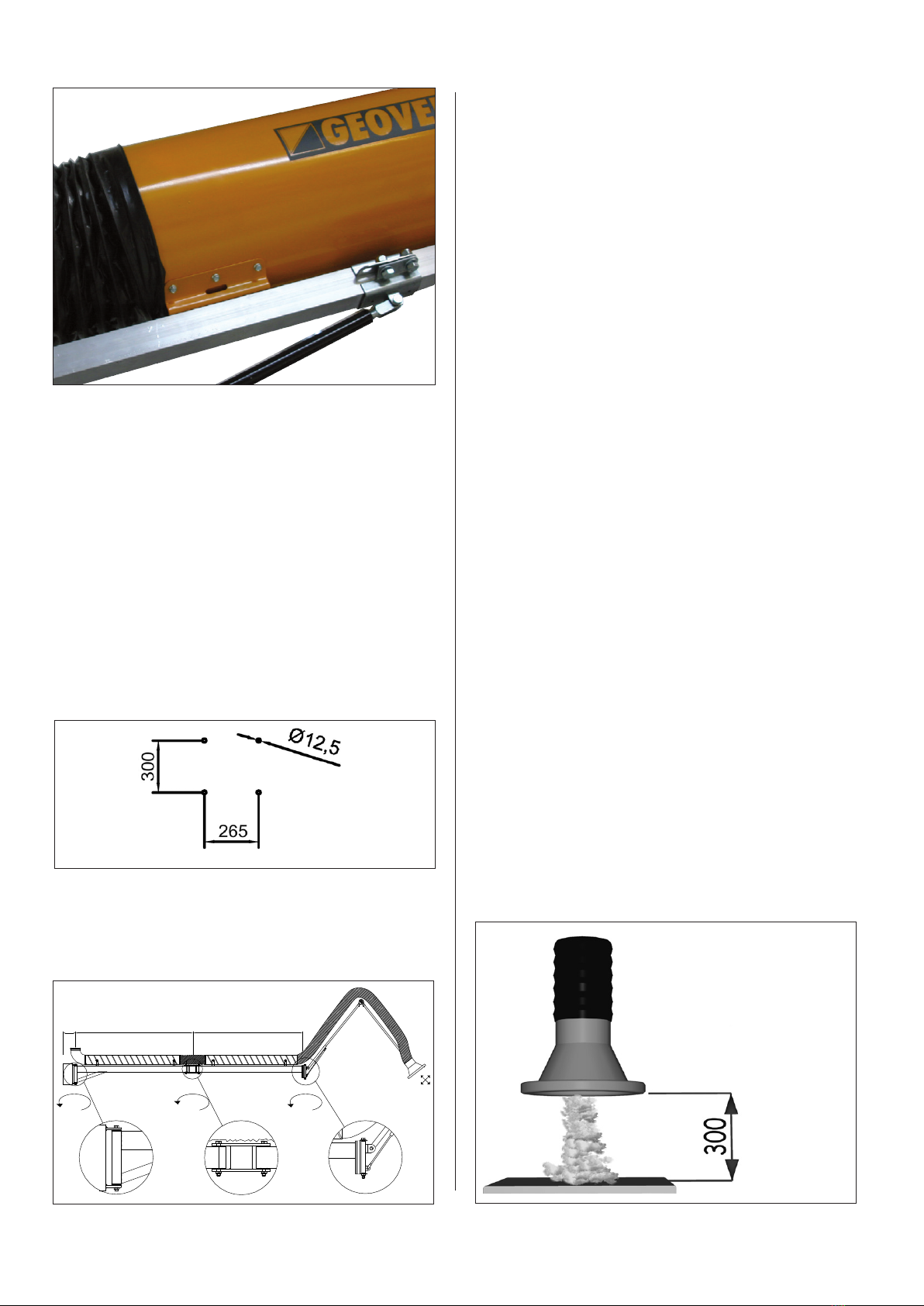

The GEOVENT ASA-3 Arm is the ideal Extraction Arm

for the extraction of welding smoke, grinding dust, fu-

mes, etc., where the well-being of the operator is in

focus with regard to lightness, ergonomics and efficien-

cy of the Arm.

The Extraction Arm is not suitable for the extraction of

aluminium dust, flour, textile dust nor sawdust or other

media, which are connected with danger of explosion,

without specific approval from Geovent A/S.

The hose may be damaged and leaky via outer loads,

e.g. by a screw driver. Avoid such load in order to safe-

guard a long life.

1.3 Handling

Always use gloves when handling. During transportati-

on all lifting must be in the arm. Note that it is possible

to pinch your fingers between the gas spring and arm.

When the arm is monuntet, it may only be handled by

the hood

1.4 Technical data

ASA-3

Art no. Description Weight

ASA-01 2,0 m - ø 80 mm 9 kg

ASA-05 2,0 m - ø 80 mm - w. damper 9 kg

ASA-11 3,0 m - ø 80 mm 10 kg

ASA-15 3,0 m - ø 80 mm - w. damper 10 kg

ASA-02 2,0 m - ø 100 mm 9 kg

ASA-06 2,0 m - ø 100 mm - w. damper 9 kg

ASA-12 3,0 m - ø 100 mm 10 kg

ASA-16 3,0 m - ø 100 mm - w. damper 10 kg

ASA-22 4,0m - ø100 mm 12 kg

ASA-26 4,0m - ø100 mm - w. damper 12 kg

ASA-03 2,0 m - ø 125 mm 9 kg

ASA-07 2,0 m - ø 125 mm - w. damper 9 kg

ASA-4

med alu-rør

ASA-3

med slange