6

Precautions

A. Before operating your handpiece, be sure that the Collet Release Ring is

in the “S” or secure position. Failure to do so (referred to as “locked rotor

condition”) will cause the motor to stall and could possibly cause motor

damage.

B. Do not attempt to change tools or rotate the Collet Release Ring while the

handpiece is running. This action will stop the motor abruptly, cause parts

damage, and could also possibly cause motor damage.

C. During use, avoid stalling the motor by pushing too hard on the work tool

or by exceeding the torque capacity of the handpiece motor.

D. The Gesswein Power Hand 3 Rotary Handpiece is designed not to

overheat with normal use. It can be used continuously and will provide

efficient, longlife performance if you apply just enough machining and

polishing pressure to maintain full motor speed.

E. The 3⁄32" (2.35mm), 1⁄8" (3.2mm) and 3.0mm collets are manufactured to

accept 3⁄32", 1⁄8" and 3.0mm ± 0.0008" shank tools respectively. Use only

tools that correspond to the collet size being used.

F. Do not use your handpiece in water or oil, and never allow any oil, water

or other fluids, dirt, or wood dust to enter the inner casing. Failure to

keep foreign matter out of the inner casing will cause damage to the ball

bearing assemblies.

G. Do not subject the power cord on the handpiece to sharp bending or

rough treatment. Such treatment could break the cord wires or damage

the male connecting pins and female cord connectors.

H. Be careful not to point the handpiece at any part of the body while it is

running, particularly during startups.

I. Be careful when using Wire Burnishing Tools. DO NOT USE THESE TOOLS

AT SPEEDS FASTER THAN 14,000 -15,000RPM. Each tool is made of

individual piano wire. Operating a Wire Burnishing Tool at higher than

recommended speed could cause the wire to come free from the hub.

7

Replacement of carbon brushes

Gesswein Power Hand 3 motors use a spring tension-type carbon brush

assembly. The approximate life of these brushes is 800-1,000 hours. Use the

set of two replacement carbon Brushes supplied with your handpiece when

it becomes necessary to replace worn brushes. (Brushes should be changed

when handpiece is not running at maximum speed, or if it sounds as though

it’s running out of gas.) Please note that in the event you must change the

brushes, it is important that both be replaced at the same time. Replacement

of only one carbon brush will cause motor damage.

Instructions for replacing Carbon Brushes

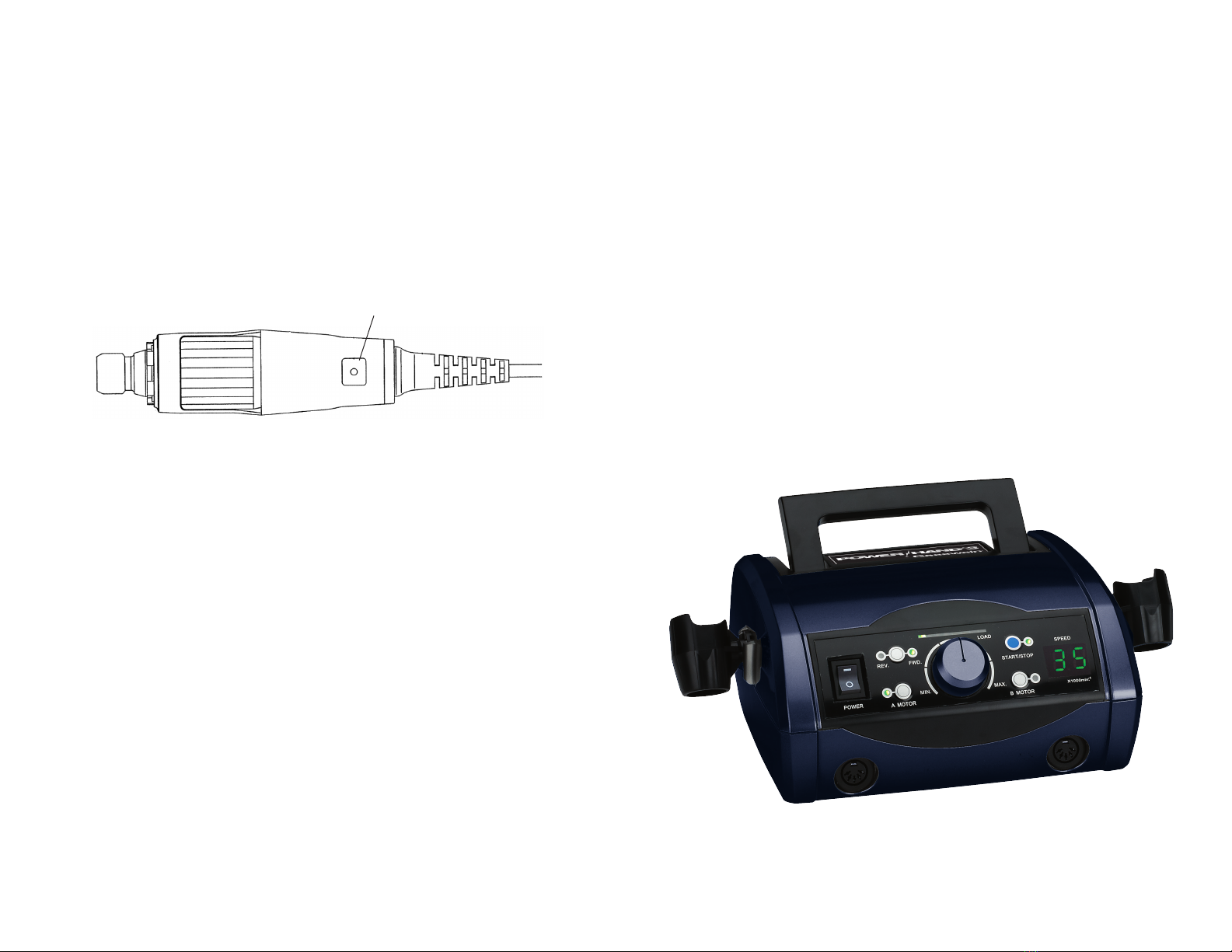

1. Disconnect the handpiece from the controller.

2. Remove the screw on the back of the motor cover.

3. Detach the motor cord from the motor by grasping the motor cord and

pulling backwards. Do not hold the motor cap when pulling backwards

to avoid damaging the On/Off switch (Fig. 3).

Fig. 3