:.

~

·

················~~:·:~:·::·~·;···1

'

_ :

co

:-=

.~

~

~

\J

o

dllll~==

'level

\ \ \ \ I

COLOR

I

A

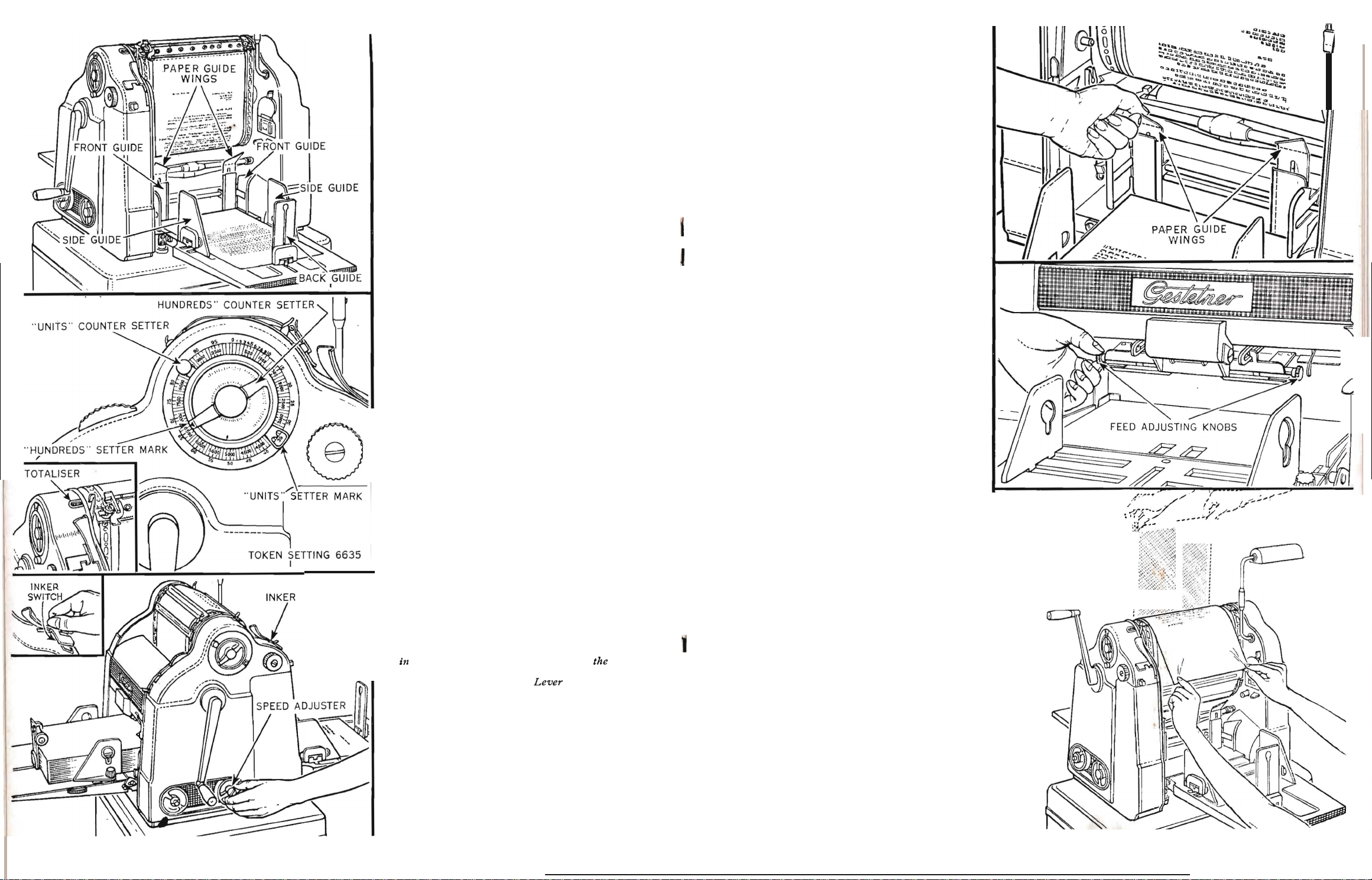

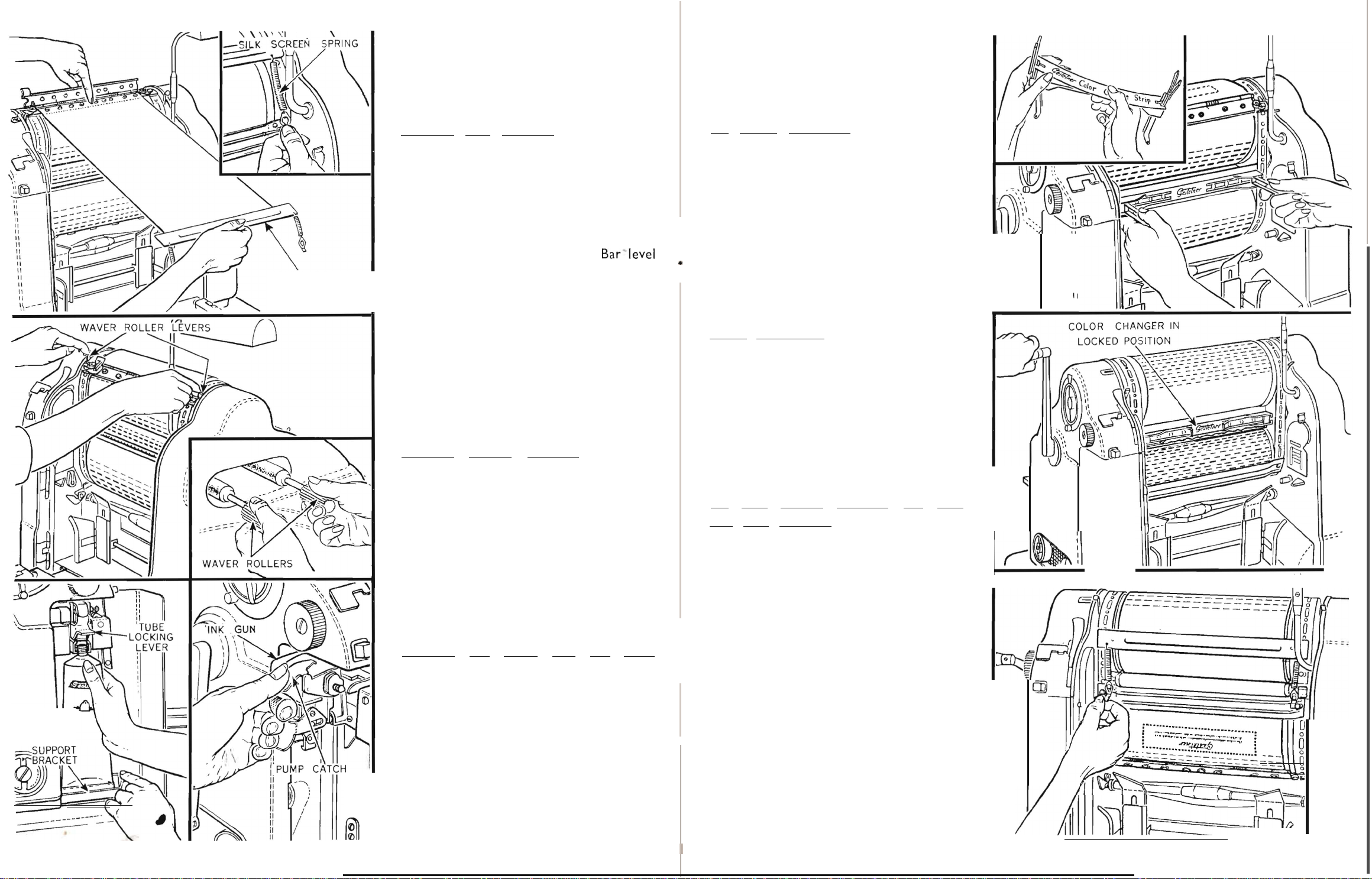

Remove

Silk

Screen.

Turn Handle

clockwise until Spring Bar

is

opposite

Waver

Roller Levers. Disengage the

two

Silk Screen Springs, lift

up

Spring Bar with

the

right hand and

turn

Handle anti-clock-

wise until Stencil Fixing Bar

is

above Top

Cylinder.

Lift

up

Stencil Fixing Bar Cover

then, while holding

the

Spring

..

.

"

I,

I ,

II

II

"

"

"

II

"

II

11

II

11

"

"

"

"

II

II

II

II

II

I I

II

.

with the Top Cylinder, disengage Silk

S

PR

I

NG

BAR

Screen Heading

by

pushing it backwards

using slot provided and

\Ift

Screen away

from Machine.

B

Remove Waver Rollers. Depress

Waver

Roller Levers and withdraw

Waver

Rollers from Machine.

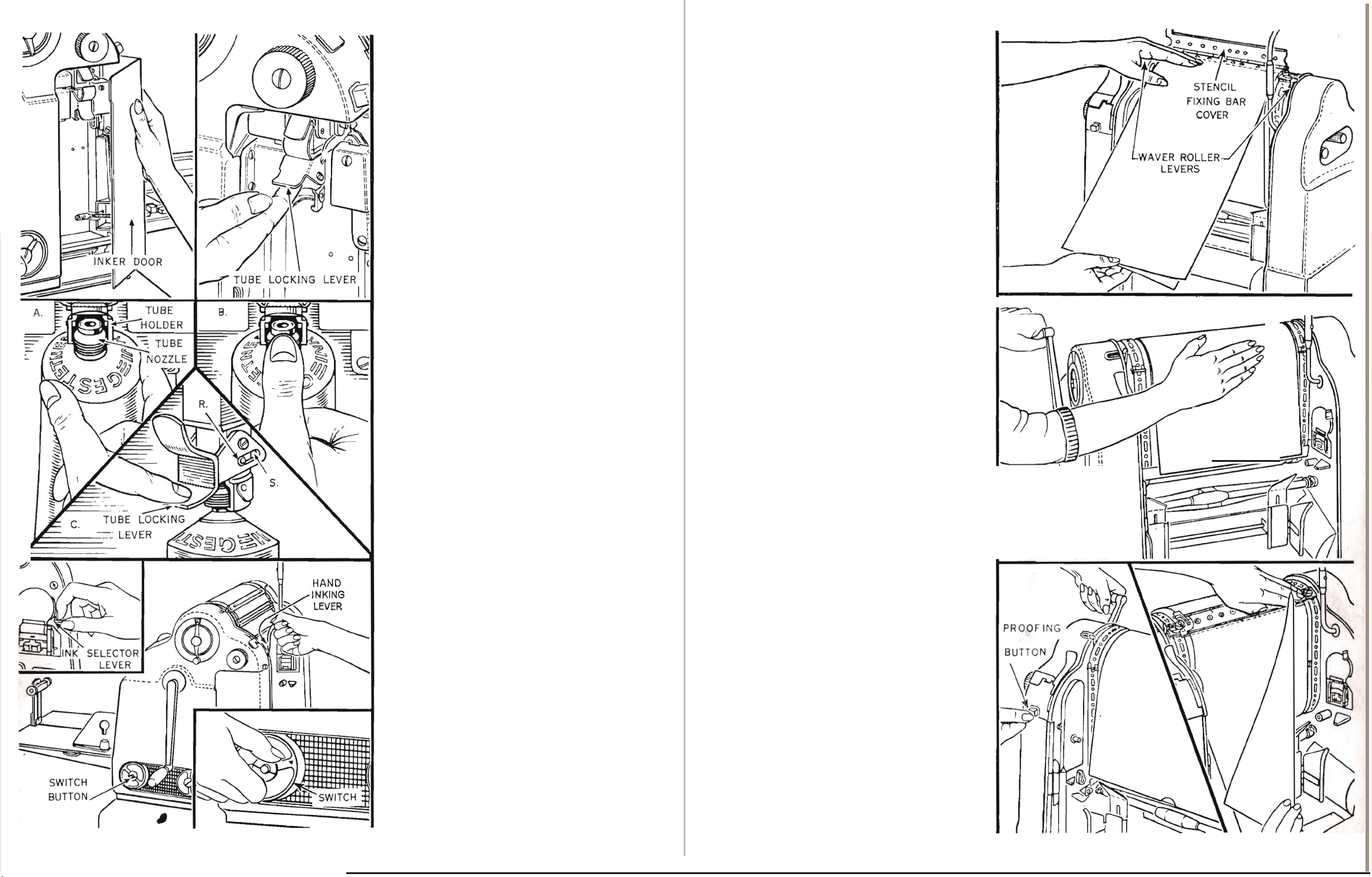

c

Remove Ink

Tube

and Ink Gun.

Open Inker Door.

Raise

Tube Locking

Lever, hold down Tube Support Bracket,

remove Ink Tube and replace its cap.

Depress Pump Catch and withdraw

Ink

TUBE

Gun. Close Inker Door.

10

11

CHANGING

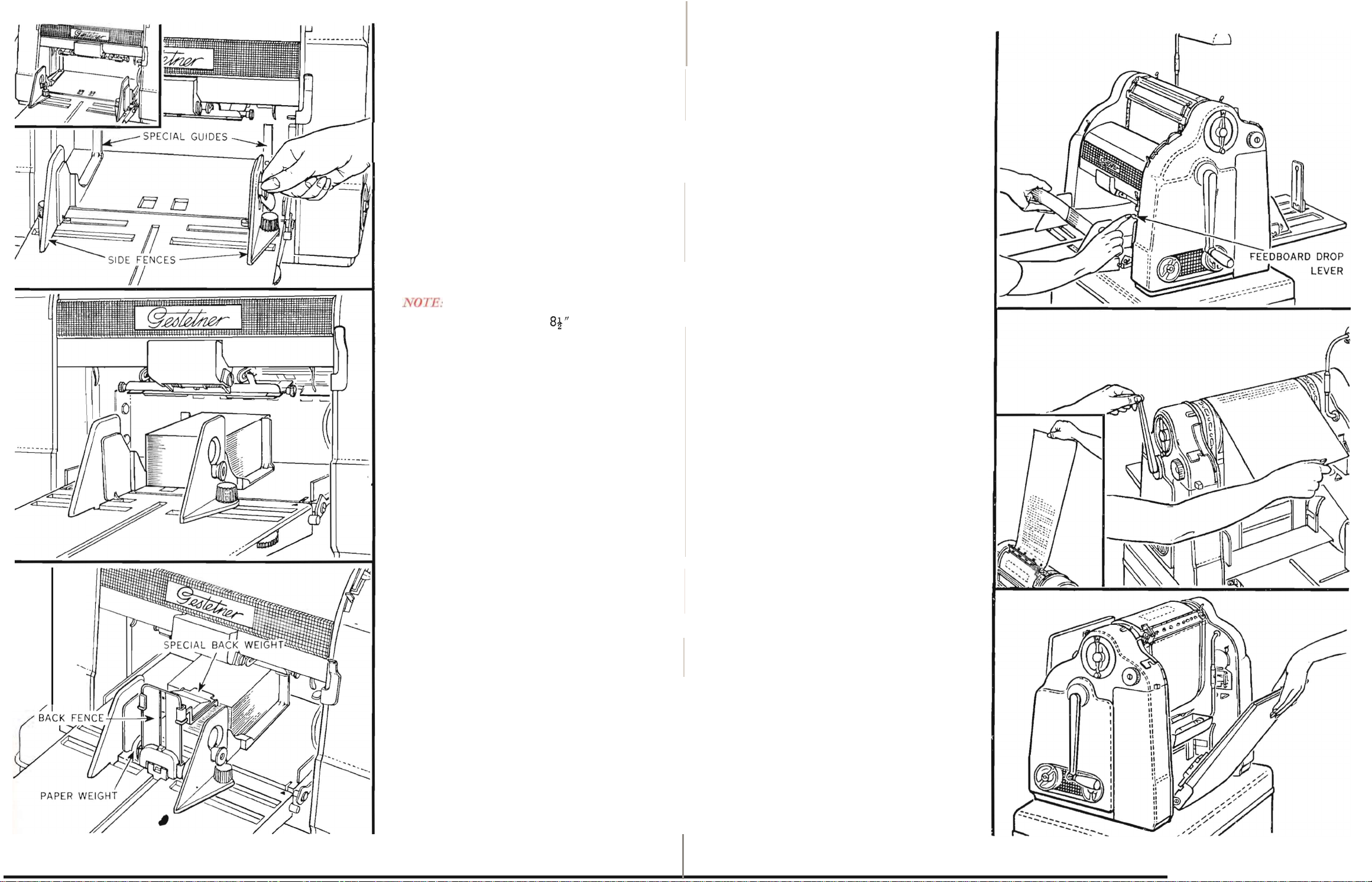

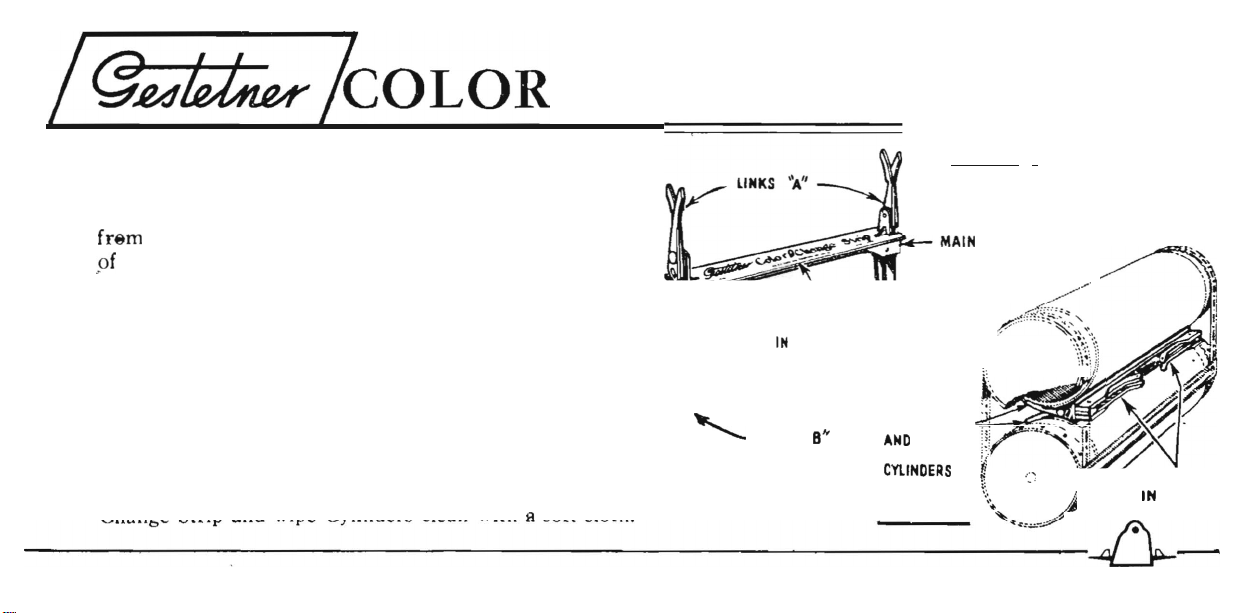

D

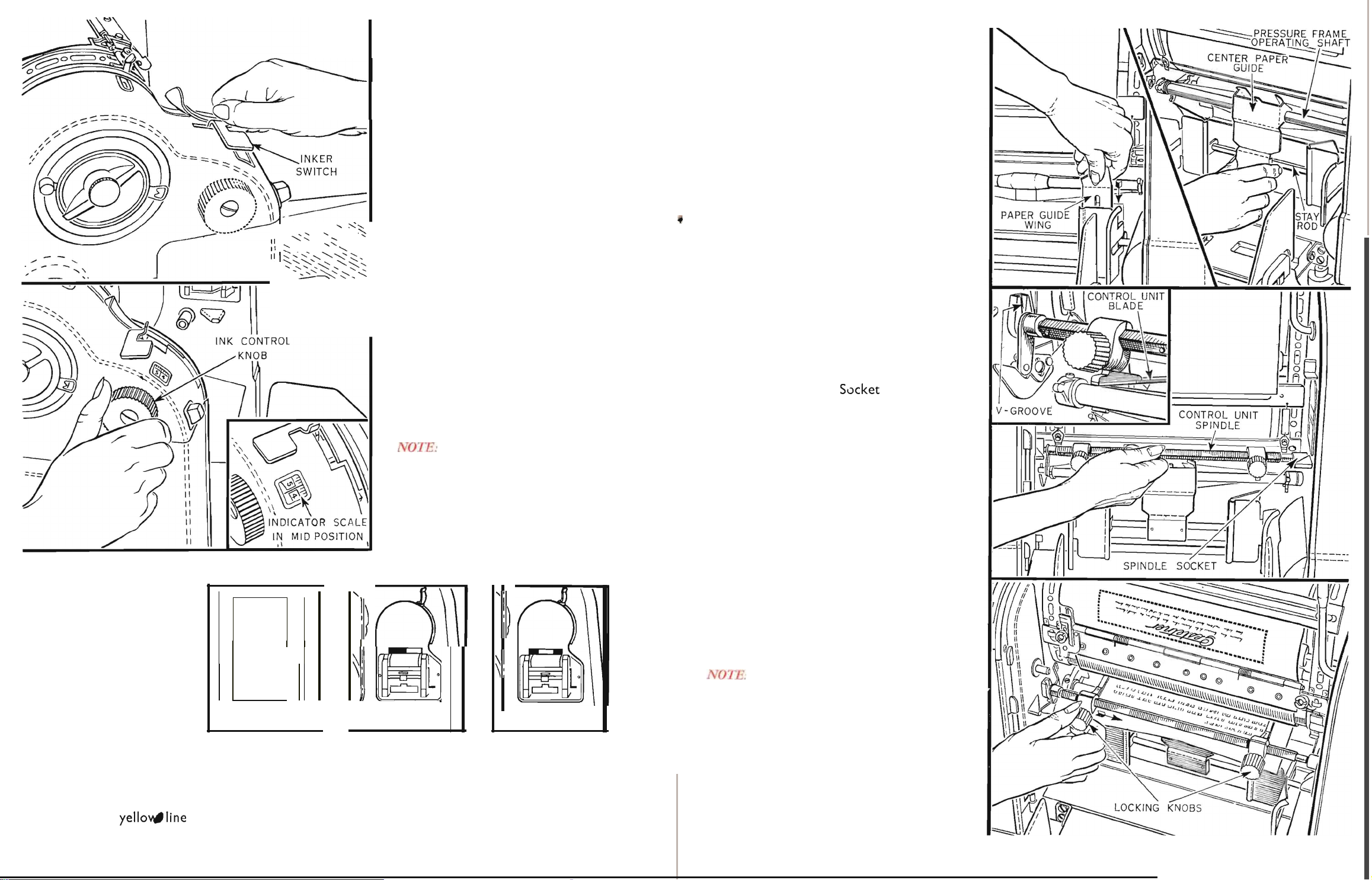

Fit

Color

Changer. Place a Color

Change Strip (printing upwards) firmly on

the

main

bar of the Color Changer. Hold

the

Color Changer

by

its Levers and insert

it between

the

Cylinders, at

the

back

ofthe

Machine, with the pronged links inwards.

Fold

Levers fully inwards

to

lock.

E

Clean Cylinders. Turn Handle slowly

for one complete revolution. Open

Levers outwards, wi

thdraw

Color Changer,

discard

Color

Change Strip and wipe

Cylinders clean with a soft cloth.

F

Fit

new

Waver

Rollers, Ink Gun

and

Silk

Screen.

Insert new

Waver

Rollers fully into Machine and raise

Waver

Roller Levers. Turn Handle

to

check

that

Waver

Rollers rotate and oscillate. Insert

new

Ink

Gun into Machine making sure

that

the

pointed end fits into its holder. Push

Ink Gun inwards until locked

in

position

by

the Pump Catch.

Turn Handle until Stencil Fixing Bar

is

at

top

of Machine.

Raise

Fixing

Bar

Cover

and engage Heading of new Silk Screen

with studs of Stencil Fixing Bar. Hold

Spring Bar

of

Silk Screen and

turn

Handle until Silk Screen Springs

can

be

fastened

to

their

studs. Continue

as

from

Step 4, page 2.

II