2

Contents

Usage for the intended purpose ..............................................................................................................4

Safety note .............................................................................................................................................4

Danger ...................................................................................................................................................4

Attention................................................................................................................................................. 4

Important Notes

Page

Explanatory Notes

Scope of supply ...................................................................................................................................... 5

Description NRG 16-11S.........................................................................................................................5

Function .................................................................................................................................................5

System components ...............................................................................................................................5

Design.................................................................................................................................................... 5

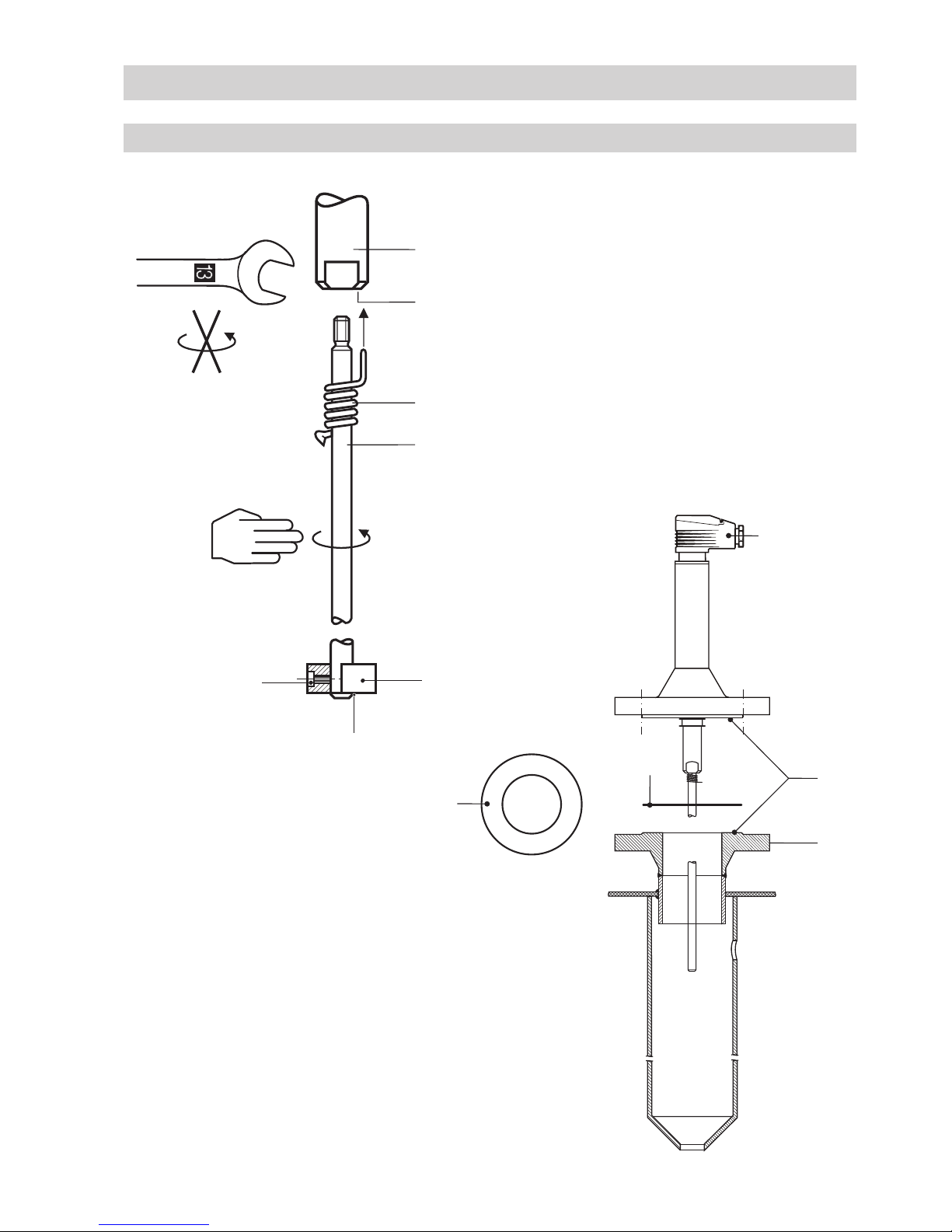

NRG 16-11S, step 1..............................................................................................................................12

NRG 16-11S, step 2..............................................................................................................................12

Attention............................................................................................................................................... 12

Important notes ....................................................................................................................................12

Tools.....................................................................................................................................................12

Installation

NRG 16-11S ...........................................................................................................................................6

Corrosion resistance ...............................................................................................................................7

Sizing .....................................................................................................................................................7

Name plate / marking .............................................................................................................................7

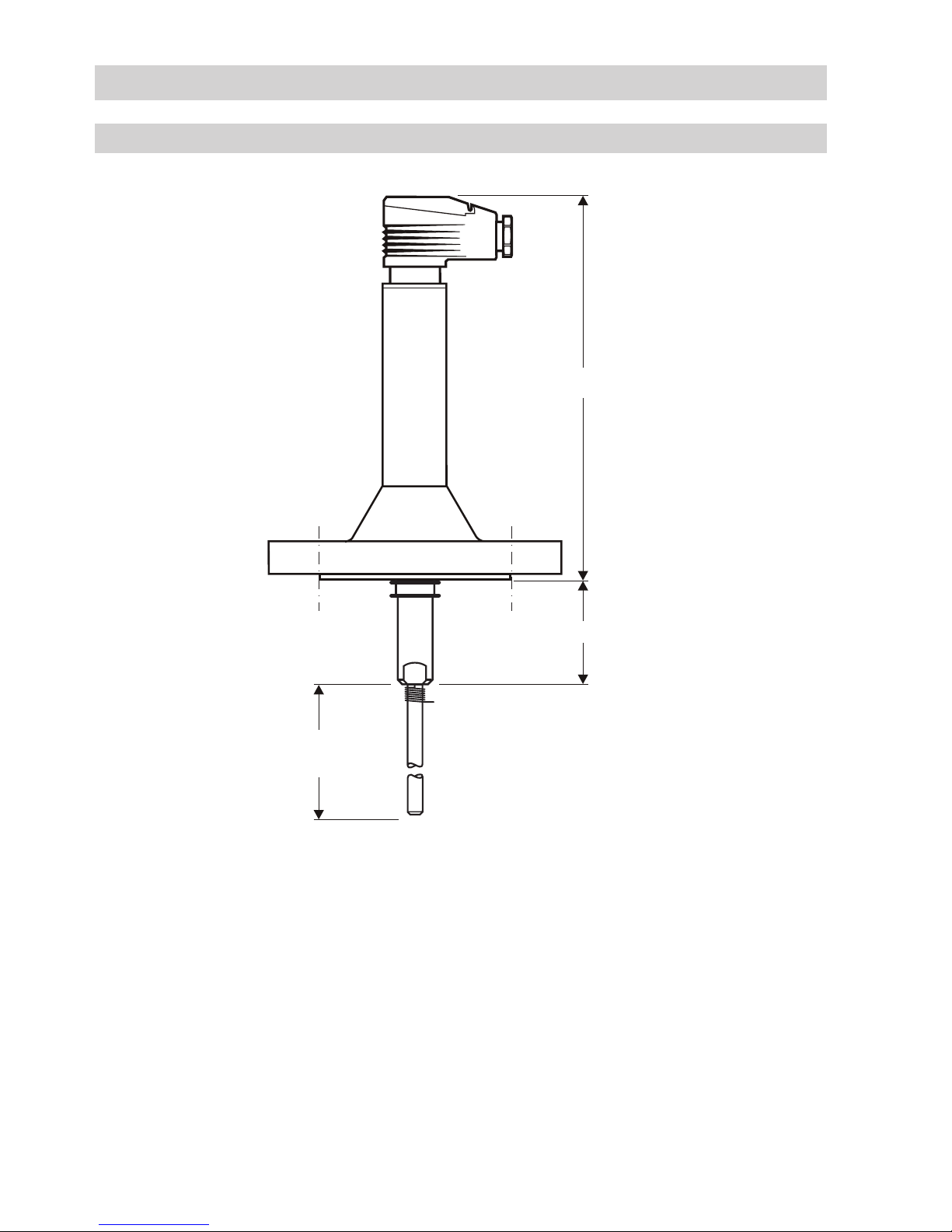

Dimensions NRG 16-11S ........................................................................................................................8

Technical Data

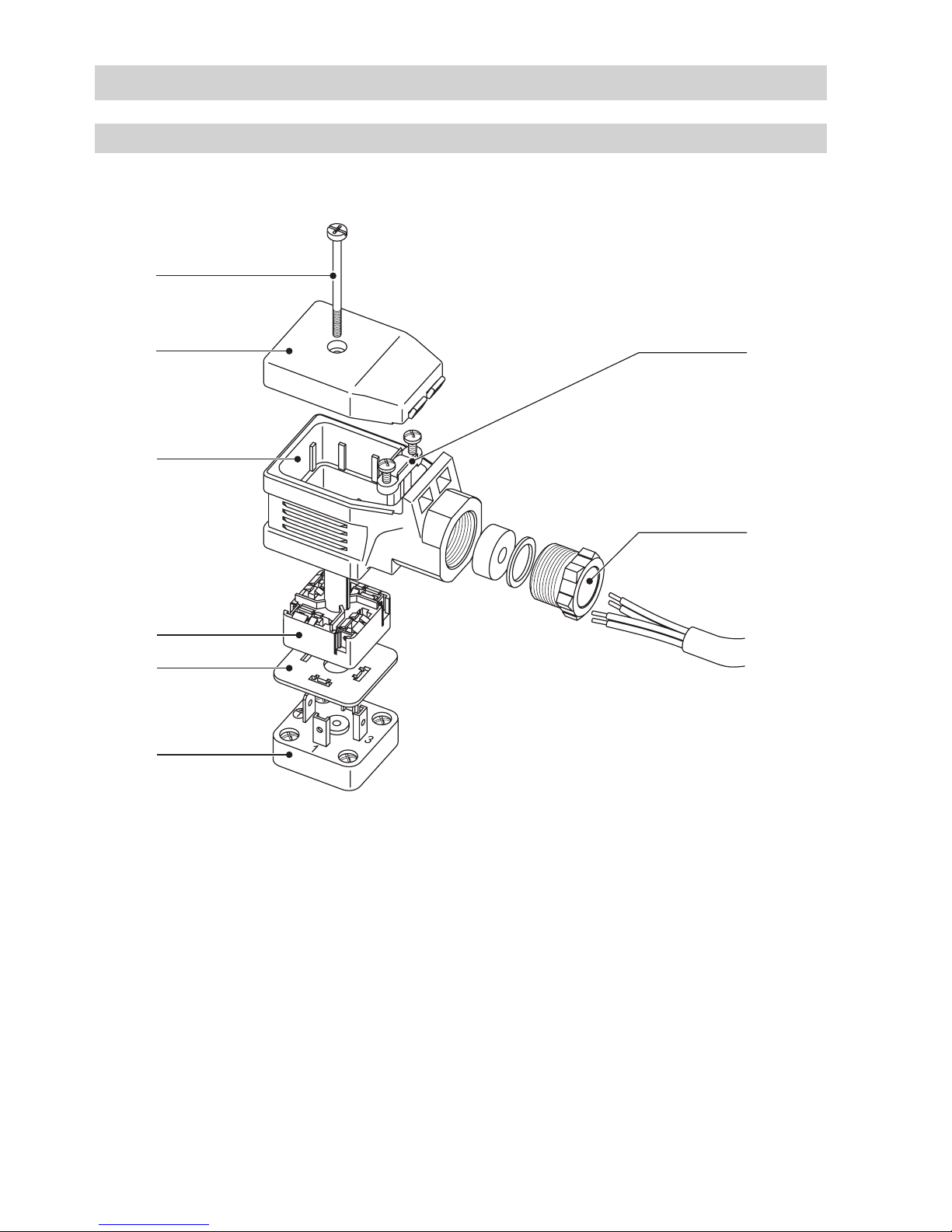

NRG 16-11S ...........................................................................................................................................9

Key.......................................................................................................................................................11

Design

NRG 16-11S .........................................................................................................................................10

Key.......................................................................................................................................................11

Functional Elements