2

Contents

Usage for the intended purpose ..............................................................................................................5

Safety note .............................................................................................................................................5

Danger ...................................................................................................................................................5

Attention.................................................................................................................................................5

LV (Low Voltage) Directive and EMC (Electromagnetic Compatibility) .......................................................5

ATEX (Atmosphère Explosible).................................................................................................................5

Important Notes

Page

Explanatory Notes

Scope of supply......................................................................................................................................6

Description .............................................................................................................................................6

Function .................................................................................................................................................6

System components ...............................................................................................................................6

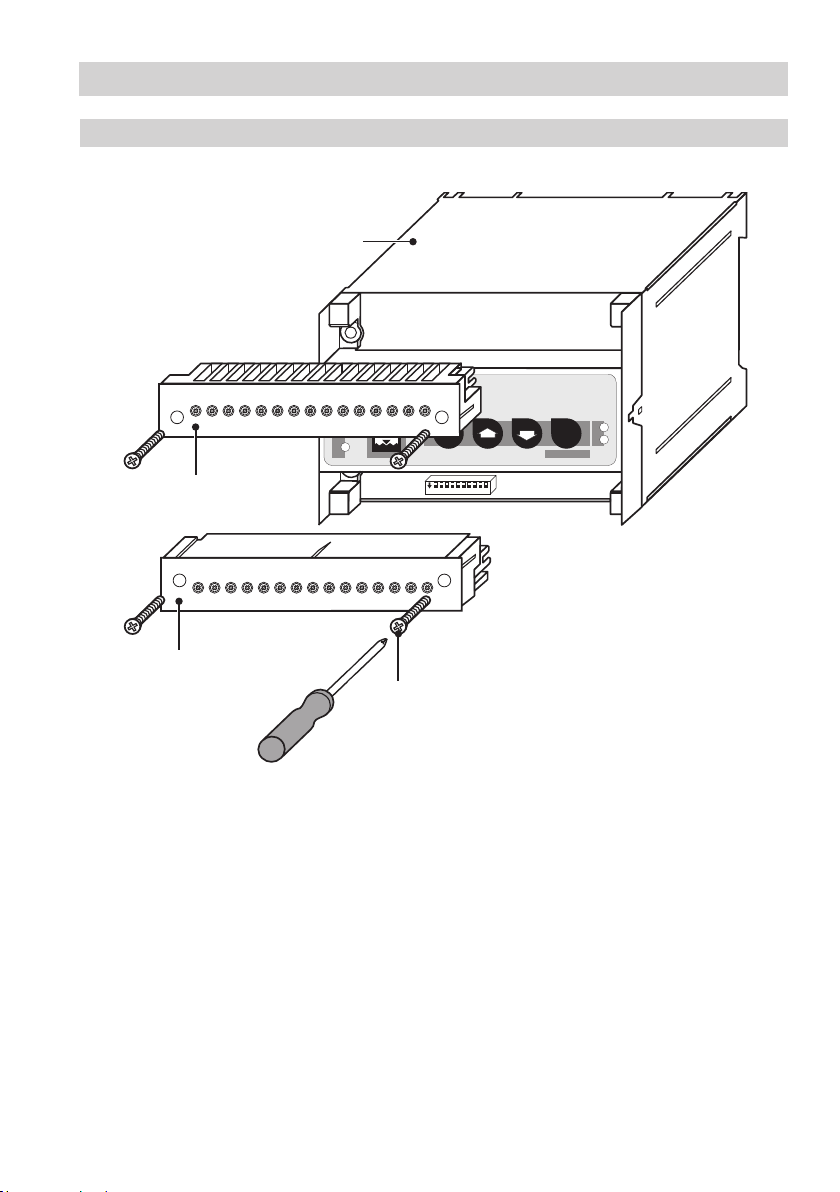

Design....................................................................................................................................................6

NRS 240..............................................................................................................................................11

Tools.....................................................................................................................................................11

Example of installation..........................................................................................................................12

Key.......................................................................................................................................................11

Installation

NRS 240................................................................................................................................................7

Corrosion resistance...............................................................................................................................8

Name plate / marking .............................................................................................................................8

Dimensions.............................................................................................................................................8

Technical Data

NRS 240................................................................................................................................................9

Key.......................................................................................................................................................11

Design

NRS 240..............................................................................................................................................10

Key.......................................................................................................................................................11

Functional Elements