ORTEC 4002D Service manual

740300 ORTEC Model 4002D Operating and Service Manual

ORTEC

Model 4002D

NIM Bin Power Supply

Operating and Service Manual

Printed in U.S.A. ORTEC Part No. 740300 19-0429

Manual Revision K

740300 ORTEC Model 4002D Operating and Service Manual

Advanced Measurement Technology, Inc.

a/k/a/ ORTEC®, a subsidiary of AMETEK®, Inc.

WARRANTY

ORTEC* warrants that the items will be delivered free from defects in material or workmanship. ORTEC

makes no other warranties, express or implied, and specifically NO WARRANTY OF MERCHANTABILITY OR

FITNESS FOR A PARTICULAR PURPOSE.

ORTEC’s exclusive liability is limited to repairing or replacing at ORTEC’s option, items found by ORTEC to

be defective in workmanship or materials within one year from the date of delivery. ORTEC’s liability on

any claim of any kind, including negligence, loss, or damages arising out of, connected with, or from the

performance or breach thereof, or from the manufacture, sale, delivery, resale, repair, or use of any item

or services covered by this agreement or purchase order, shall in no case exceed the price allocable to the

item or service furnished or any part thereof that gives rise to the claim. In the event ORTEC fails to

manufacture or deliver items called for in this agreement or purchase order, ORTEC’s exclusive liability

and buyer’s exclusive remedy shall be release of the buyer from the obligation to pay the purchase price.

In no event shall ORTEC be liable for special or consequential damages.

Quality Control

Before being approved for shipment, each ORTEC instrument must pass a stringent set of quality control

tests designed to expose any flaws in materials or workmanship. Permanent records of these tests are

maintained for use in warranty repair and as a source of statistical information for design improvements.

Repair Service

If it becomes necessary to return this instrument for repair, it is essential that Customer Services be

contacted in advance of its return so that a Return Authorization Number can be assigned to the unit.

Also, ORTEC must be informed, either in writing, by telephone [(865) 482-4411] or by facsimile

transmission [(865) 483-2133], of the nature of the fault of the instrument being returned and of the

model, serial, and revision (“Rev” on rear panel) numbers. Failure to do so may cause unnecessary delays

in getting the unit repaired. The ORTEC standard procedure requires that instruments returned for repair

pass the same quality control tests that are used for new-production instruments. Instruments that are

returned should be packed so that they will withstand normal transit handling and must be shipped

PREPAID via Air Parcel Post or United Parcel Service to the designated ORTEC repair center. The address

label and the package should include the Return Authorization Number assigned. Instruments being

returned that are damaged in transit due to inadequate packing will be repaired at the sender's expense,

and it will be the sender's responsibility to make claim with the shipper. Instruments not in warranty

should follow the same procedure and ORTEC will provide a quotation.

Damage in Transit

Shipments should be examined immediately upon receipt for evidence of external or concealed damage.

The carrier making delivery should be notified immediately of any such damage, since the carrier is

normally liable for damage in shipment.Packing materials, waybills, and other such documentation should

be preserved in order to establish claims. After such notification to the carrier, please notify ORTEC of the

circumstances so that assistance can be provided in making damage claims and in providing replacement

equipment, if necessary.

740300 ORTEC Model 4002D Operating and Service Manual

3

Copyright © 2009, Advanced Measurement Technology, Inc. All rights reserved.

*ORTEC®is a registered trademark of Advanced Measurement Technology, Inc. All other trademarks

used herein are the property of their respective owners.

SAFETY INSTRUCTIONS AND SYMBOLS

This manual contains up to three levels of safety instructions that must be observed in order to

avoid personal injury and/or damage to equipment or other property. These are:

DANGER Indicates a hazard that could result in death or serious bodily harm if the safety

instruction is not observed.

WARNING Indicates a hazard that could result in bodily harm if the safety instruction is not

observed.

CAUTION Indicates a hazard that could result in property damage if the safety instruction is

not observed.

Please read all safety instructions carefully and make sure you understand them fully before

attempting to use this product.

In addition, the following symbol might appear on the product:

ATTENTION –Consult the manual in all cases where this symbol is marked in

order to determine the nature of the potential hazards and any actions that

must be taken to avoid them

DANGER –Hazardous voltage

Protective earth (ground) terminal

Warning –Hot Surface

740300 ORTEC Model 4002D Operating and Service Manual

4

WARRANTY ......................................................................................................................................2

SAFETY INSTRUCTIONS AND SYMBOLS............................................................................................3

1. DESCRIPTION....................................................................................................................................7

2. SPECIFICATIONS ...............................................................................................................................8

3. INSTALLATION……………………………………………………………………………………………………………………..……10

3.1 UNPACKING……………………………………………………………………………………………………………………..11

3.2 SELECTING THE MAINS VOLTAGE……………………………………………………………………………………..11

3.3 CONNECTION OF THE 4002D TO A NIM BIN………………………………………………………………………11

3.3.1 Requirements for Attached Bin………………………………………………………………………..……11

3.3.2 Instructions for Attaching Bin……………………………….……………………………….………………11

4. OPERATING INSTRUCTIONS………………………………………………………………………………………………………13

5. CIRCUIT DESCRIPTION…………………………………………………………………………………………………………….…14

6. MAINTENANCE…………………………………………………………………………………………………………….…………..14

740300 ORTEC Model 4002D Operating and Service Manual

5

SAFETY WARNING AND CLEANING INSTRUCTIONS

CLEANING INSTRUCTIONS

To clean the instrument exterior:

•Unplug the instrument from the AC power source.

•Remove loose dust on the oputside of the instrument with a lint-free cloth.

•Remove remaining dirt with a lint-free cloth dampened in a general-purpose detergent and

water solution. Do NOT use abrasive cleaners.

•Allow the instrument to dry completely before reconnection it to the power source.

WARNING: If this equipment is used in a manner not specified by the manufacturer the protection

provided by the instrument may be impaired.

CAUTION: To prevent moisture inside of the instrument during external cleaning, use only enough

liquid to dampen the cloth or applicator.

740300 ORTEC Model 4002D Operating and Service Manual

6

740300 ORTEC Model 4002D Operating and Service Manual

7

1. DESCRIPTION

The ORTEC Model 4002D Power Supply is designed to supply dc power to a NIM Bin when the application

requires ±6 V, ±12 V and ±24 V power. The 4002D Power Supply can be purchased separately for use with

existing NIM Bins, or it can be ordered attached to either a 4001A NIM Bin or a 4001C NIM Bin. Mounting

hardware is supplied to make the Model 4002D compatible with all ORTEC NIM Bins. With minor mounting

modifications the 4002D can be used with most standard NIM Bins. The ORTEC 4001C NIM Bin is

recommended for use with the 4002D because the 4001C distributes the power with copper bus bars to

minimize the voltage drop at each module's power plug. The 4002D Power Supply is designed to exceed

recommended power supply specifications for Type V-H supplies as defined in DOE/ER-0457T.

Regulated dc power supplied to the attached bin by the 4002D is conservatively rated at +6 V @ 10 A, -

6V@10A,+12V@3A,-12V@3A,+24V@ 1.5A, and -24 V @ 1.5 A. These maximum output currents can be

delivered in any combination provided the total output dc power does not exceed 160 W at ambient

temperatures up to 50 C. In addition, 115 V ac is available up to 0.5 A.

Protection against overload is provided in several ways. When the heat sink temperature exceeds 95 C,

the red warning indicator is illuminated on the attached bin control panel. When the heat sink temperature

exceeds 110 C, the power supply is automatically shut down, causing both the power and temperature

indicator lights to turn off. Recovery from thermal overload is automatic when the thermal load is reduced.

Output currents from the dc supplies are internally limited to 120% of their rated values by foldback circuits.

This provides overload and short-circuit protection. On the +6 V and -6 V dc supplies, crowbar circuits limit

the output voltage to 7.5 V to protect integrated circuits. Fuses protect the ac inputs to the power supply.

An external slide switch allows selection of either 115 or 220 V ac as the power input. An international

standard IEC power connector permits power cords and plugs that meet local electrical standards to be

used for the input power. Control of the primary power is provided by the On/Off switch on the NIM Bin

control panel.

Connection of power and control lines to the NIM Bin is provided by the standard interface connector

specified in DOE ER-0457T. Mechanical mounting of the power supply to the bin is with brackets utilizing

the standard bolt pattern specified in DOE/ER-0457T.

740300 ORTEC Model 4002D Operating and Service Manual

8

2. SPECIFICATIONS

INPUT 115V-120V or 220V-240V, 50/60 HZ, 490 VA (plus any load on 115 V ac OUTPUT). An external

slide switch selects nominal input voltages of 115 or 220 V ac.

DC OUTPUTS Maximum rated output currents are:

DC Maximum DC Maximum

Voltage Current Voltage Current

+6 V 10 A -6 V 10 A

-12 V 3 A -12 V 3 A

+24 V 1.5 A -24 V 1.5 A

ENVIRONMENTAL Maximum dc output power from 0 to 50°C is 160 W. Derate 3%/°C for 50 to 60°C.

Relative Humidity 0% to 80% noncondensing. Altitude to 3000m.

115 V ac OUTPUT Unregulated voltage. Maximum current limited only by the input fuses when operated

in the 115-V ac setting. Limited to 0.5 A on the 220-V ac setting when the dc load is 160 W. Output voltage

is nominally 115 V ac in the 115-V and 220-V input modes.

REGULATION <± 0.1%(typically±0.05%) for ±12V and ±24 V, and <±0.2% (typically ±0.1%) for ±6 V over

the combined range of zero to full load with the specified input voltage range for measurements made within

a 1-minute period. Regulation <±0.3% for ±12 V and ±24 V, and <±0.6% for ±6 V over any 24-hour period

at constant ambient temperature for the same load and input ranges after a 60-minute warmup.

LONG TERM STABILITY DC output voltages change <±0.5% (after a 60-minute warmup) over a 6-month

period at constant load, line voltage, and ambient temperature.

OUTPUT IMPEDANCE <0.3 Ω at any frequency up to 100 kHz for the dc outputs.

TEMPERATURE COEFFICIENT <0.02%/°C, 0 to 60°C.

NOISE AND RIPPLE <3 mV peak-to-peak for any output as observed on a 50-MHZ bandwidth oscilloscope.

VOLTAGE ADJUSTMENT ±2% minimum range. Resettability <±0.05% of the supply voltage.

RECOVERY TIME <100μs to return to within ±0.1% of the rated voltage for all dc outputs for any input

voltage change within the rated range or for a change of load current from 10% to 100% of full load.

CIRCUIT PROTECTION Both input power lines include fuses. The power supply is automatically turned

off by an internal switch if the temperature decreases to a safe value. Provision is made for activating a

temperature warning light on the NIM Bin control panel to advise that the temperature limit is being

740300 ORTEC Model 4002D Operating and Service Manual

9

approached. This warning occurs at and above a heat sink temperature of 95˚C. All dc outputs include a

current foldback circuit to limit the output current to nominally 120% of the rated value. This feature provides

short-circuit and overload protection. Recovery is automatic after removal of the overload condition. Over-

voltage protection for the ±6-V outputs prevents these outputs from exceeding ±7.5 V, respectively, to

protect the integrated circuits that are commonly powered by these supply voltages.

WEIGHT 11.3 kg (25 lb) net weight, 15.9 kg (35 lb) shipping weight.

DIMENSIONS 43.2 cm (17.0 in.) wide, 26.9 cm (10.6 in.) deep, and 8.9 cm (3.5 in.) high.

740300 ORTEC Model 4002D Operating and Service Manual

10

3. INSTALLATION

3.1 UNPACKING

Unpack the unit, being careful to retain all packing materials until the unit has been checked for possible

concealed damage. The power cord is packed with the unit and attaches to a three-pin connector that is

mounted on the rear of the 4002D Power Supply.

3.2 SELECTING THE MAINS VOLTAGE

The 4002D Power Supply is designed so that the transformer primary can be connected in a

configuration that is compatible with the available mains voltage. Check the voltage level to be used and

select the appropriate range on the 4002D Power Supply. The normal selection is either 115 V ac or 220

V ac, and the selection is made using the slide switch on the side of the power supply near the power

cord.

3.3 CONNECTION OF THE 4002D TO A NIM BIN

The 4002D Power Supply is normally attached to an ORTEC 4001C Modular System Bin. However, the

4002D is designed to DOE/ER-0457T specifications and may be attached, in the space provided, to any

bin manufactured to those specifications.

3.3.1 Requirements for Attached Bin

The 4002D Power Supply is designed to provide very high currents to NIM modules that contain heavy

loads. The NIM Bin used with this power supply must be capable of handling the large currents

demanded by those loads. The power On/Off switch mounted on the bin and its associated primary

circuit wiring must be rated to handle 5 A.

The bin wiring distributing the dc voltages must also have an impedance low enough to yield negligible

voltage drops at the rated currents for the supply. Although the ORTEC Model 4001A NIM Bin will

function acceptably with the 4002D power supply, the Model 4001C Bin is strongly recommended as the

more desirable choice. The ORTEC Model 4001C Bin employs copper bus bars for power distribution.

This typically results in more than a factor of 10 lower voltage drop at maximum current.

CAUTION: If the input voltage selection slide switch is changed to the “230V” setting, the input fuses

must be changed to the 5x20mm 5A slow-blow fuses included in a bag screwdriver to pry open the

cover on the power input module and remove the fuse drawer containing the fuses; replace the ¼” x

1¼” fuses with the 5x20mm fuses.

If the input voltage selection slide switch is subsequently changed to the “115V” setting, the input fuses

must be changed back to the ¼” x 1¼” 8A slow-blow fuses.

Failure to use the proper fuses could result in internal damage to the power supply.

740300 ORTEC Model 4002D Operating and Service Manual

11

3.3.2 Instructions for Attaching Bin

For attachment to a bin other than an ORTEC bin, please refer to the appropriate instruction manual.

The On/Off switch and other controls necessary to operate the Power Supply are part of the bin and not

furnished with the Power Supply.

For attachment to the ORTEC bin, the following steps are advised:

Always disconnect the power cord at the power supply chassis before connecting or disconnecting the

bin-power supply connector (PG13-PG14). Failure to do so will result in a shock hazard at PG14 and can

also damage the power supply or the contents of the bin.

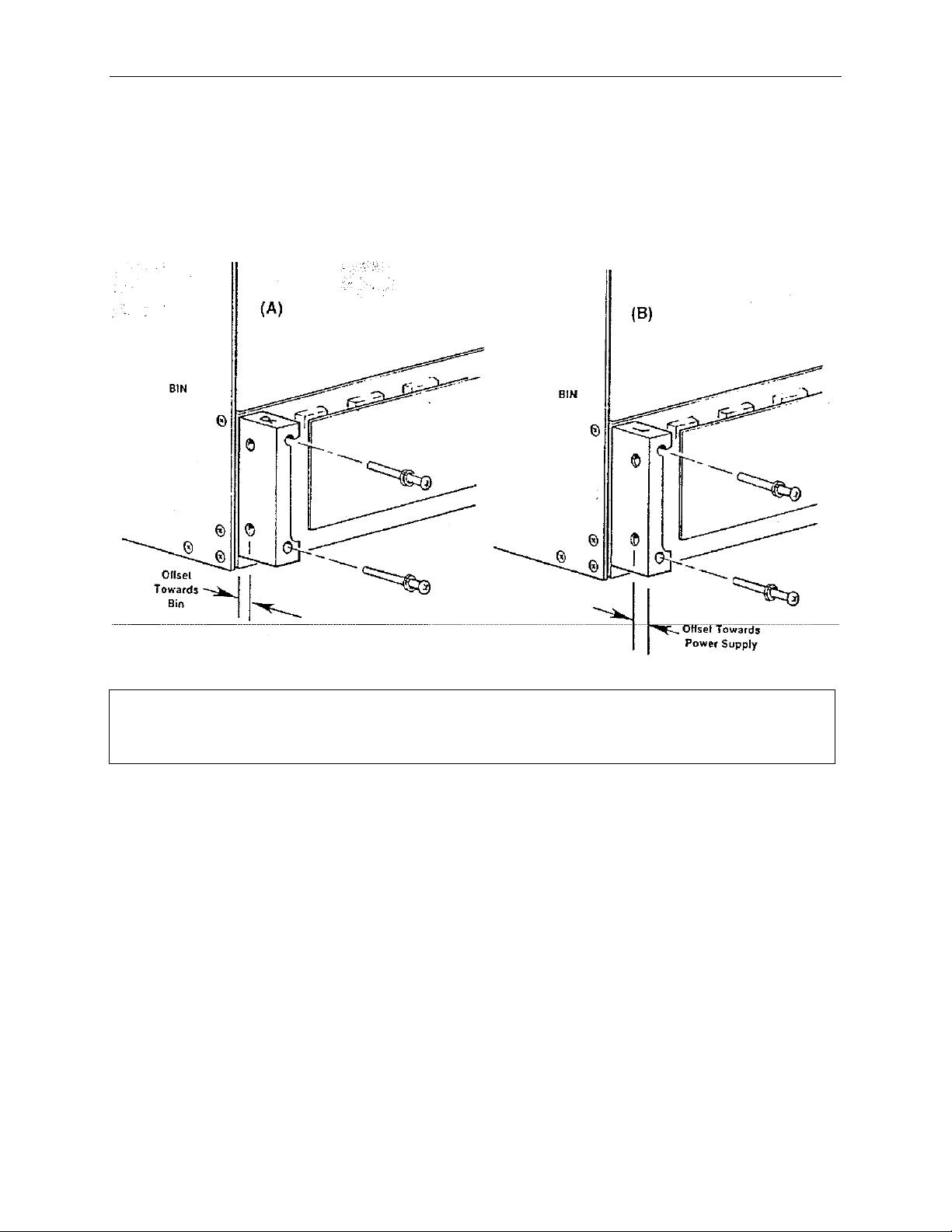

1. The adapter blocks used to mount the Power Supply to the bin are shipped attached to the Power

Supply. These adapter blocks are polarized and mount in one orientation for ORTEC 4001A and 4001 C

Bins, and in another orientation for older ORTEC and other manufacturers' bins. One adapter block is

marked on top with an "L", and the other adapter block is marked on top with an "R".

2. First remove the adapter blocks from the Power Supply. They will be mounted to the bin and then

the Power Supply will be mounted to the adapter blocks.

3. Using the ORTEC 4001A/C Bins, mount the adapter block with an "R" on top to the side of thebin that

has the On/Off switch, using two 10-32 screws and lockwashers. Next, mount the adapter block with an

"L" on top to the other side of the bin, using two 10-32 screws and lockwashers. Note that the mounting

WARNING: Always disconnect the power cord at the power supply chassis before connecting or

disconnecting the bin-power supply connector (PG13-PG14). Failure to do so will result in a shock

hazard at PG14 and can also damage the power supply or the contents of the bin.

740300 ORTEC Model 4002D Operating and Service Manual

12

holes in the adapter blocks that are used to mount the Power Supply are closer to the bin than to the

Power Supply as shown in Figure 1(A).

4. Place the bin on a table with the back part facing you. Place the power supply in the proper mounting

position, leaving enough space between the two pieces to attach the interface connector.

5. After ensuring that the power cord is disconnected, mate the interface connector, being careful to

align the polarizing pins. Fold and form all wiring close to the connector edges to prevent any wires from

being pinched and producing a short circuit in succeeding steps.

6. Mount the power supply to the adapter blocks by securely tightening the four 1/4-inch black 10-32

screws between the sides of the Power Supply and the adapter blocks, being careful not to pinch any

wires or to use undue force on any parts. With the adapter blocks in proper orientation, the side of the

Power Supply will closely butt to the back of the bin.

7. When using older ORTEC bins, or those manufactured by other vendors, the orientation of the

adapter blocks may need to be changed to ensure that the Power Supply will closely butt to the

back of the bin. In this case, mount the adapter block marked with an "L" on top to the side of the bin

that has the On/Off switch, using two 10-32 screws and lockwashers. Next, mount the adapter block

with an "R" on top to the other side of the bin using two 10-32 screws and lockwashers. Note that the

mounting holes in the adapter blocks that are used to mount the Power Supply are closer to the Power

Supply than to the bin as shown in Figure 1(B).

8. Perform steps 4, 5, and 6 listed above.

740300 ORTEC Model 4002D Operating and Service Manual

13

4. OPERATING INSTRUCTIONS

The available current from the power supply is specified in Section 2, "DC OUTPUTS." Care must be used

to ensure natural convection of heat dissipation by the heat sinks and power transformer. When used at

maximum power loading on a bench or tabletop, the bin and power supply should be in an open space,

placed upon blocks at least 1 in. off the table mounting surface to allow maximum ventilation. When

used in a rack, attention should be paid to placement of other heat-generating equipment Adequate

unobstructed space on all sides is necessary for convection ventilation and cooling. If the bin contains

other heat-generating equipment, a blower may be advisable to remove the dissipated heat.

When it is necessary to rack mount several bins and power supplies, especially when other heat-

generating equipment is located within the rack, the term 11 ambient temperature" becomes less

clearly defined. A better guide to maximum power loading capability is to monitor the heat sink

temperature. Never allow the heat sink temperature to run continuously above 95°C. Although this is

not the maximum operating temperature, any additional temperature rise due to other conditions of

the system may force the supply out of tolerance and may cause it to automatically shut down

operation. Should your operation produce a heat sink temperature of 85°C, a blower to remove the heat

is recommended.

740300 ORTEC Model 4002D Operating and Service Manual

14

5. CIRCUIT DESCRIPTION

The 4002D Power Supply produces six dc output voltages. A power transformer changes the input ac

line voltage into six separate low-voltage sources. The sources or windings are full-wave-rectified,

capacitor-filtered, and regulated by electronic series regulator circuits. The regulator circuits provide

short-circuit and current limiting protection.

Each of the six series regulator circuits are nearly identical in operation; they are physically different

only in component values for each supply and in the pass element for the ±6 V supply. The regulator can

operate in two modes: first and normal is the voltage regulation mode; second is the current-foldback or

current-limiting protection mode.

The regulator will operate in the voltage regulation mode at any current output up to and including the

full rated output of a particular supply. When current output beyond ∼150% of the rated output is

required, which includes a direct short across the output terminals, the regulator automatically converts

to a current-foldback mode. This provides power limiting and protection of the regulator's circuitry and

components. When excessive current demands are removed, the regulator resumes the voltage

regulation mode.

6. MAINTENANCE

The 4002D Power Supply needs no routine maintenance or adjustment.

740300 ORTEC Model 4002D Operating and Service Manual

15

Table of contents

Other ORTEC Power Supply manuals

Popular Power Supply manuals by other brands

Harley Benton

Harley Benton Powerplant owner's manual

Agilent Technologies

Agilent Technologies E3631A user guide

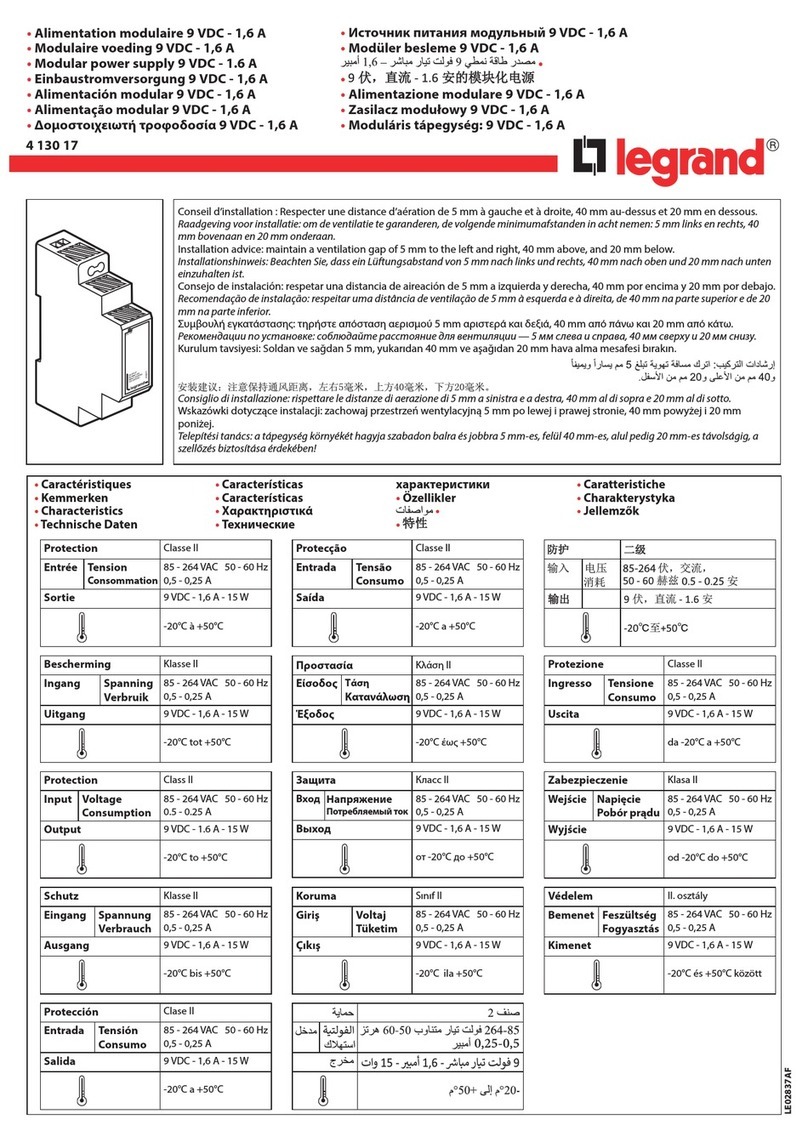

LEGRAND

LEGRAND 4 130 17 quick start guide

CommScope

CommScope RUCKUS SmartZone 300 Quick setup guide

AlzaPower

AlzaPower APW-PS200 user manual

Precision Power

Precision Power PP36PB-12 user manual