1

Contents

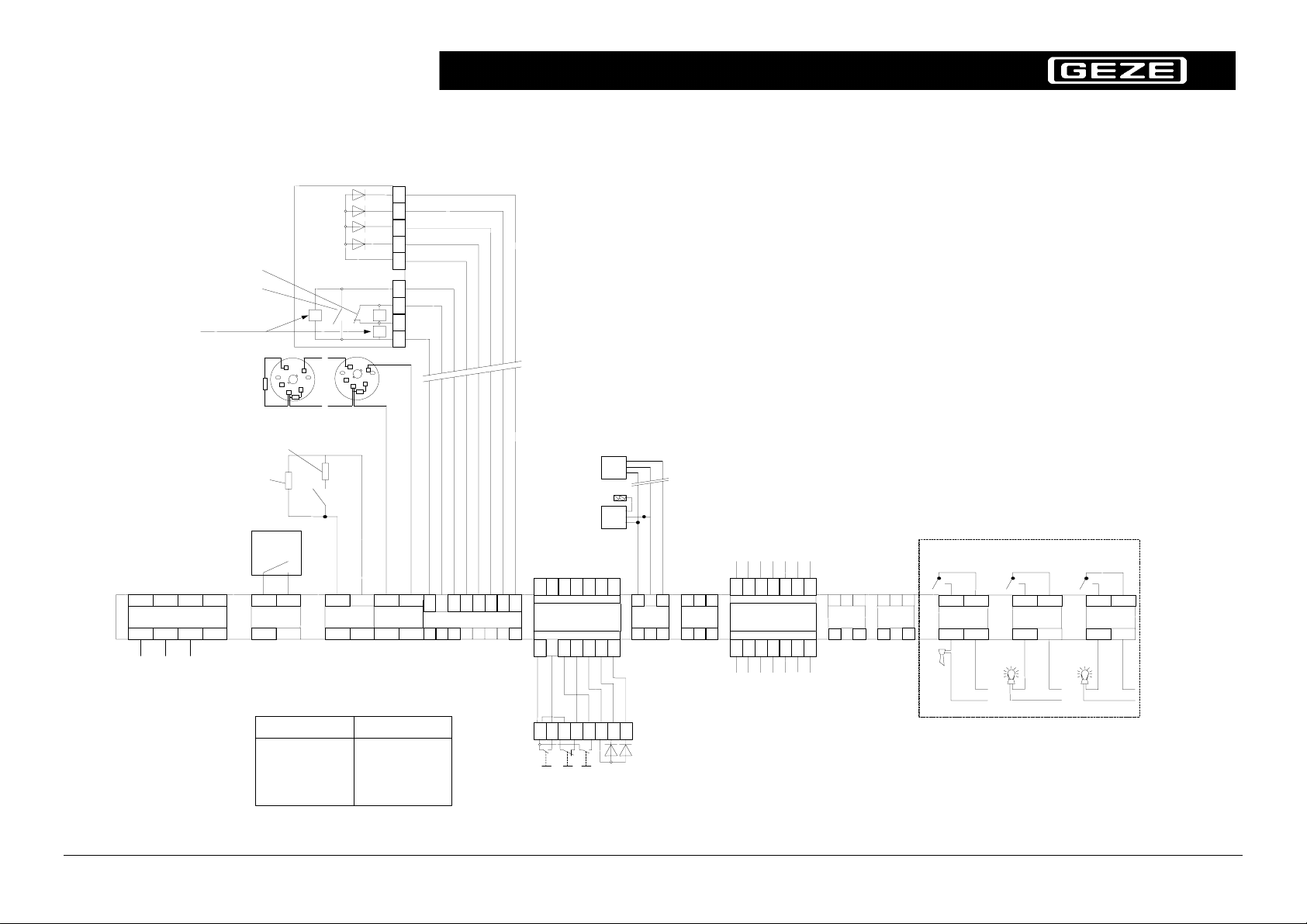

1. Short description...............................................................................................................................................................2

2. Layout plan..........................................................................................................................................................................3

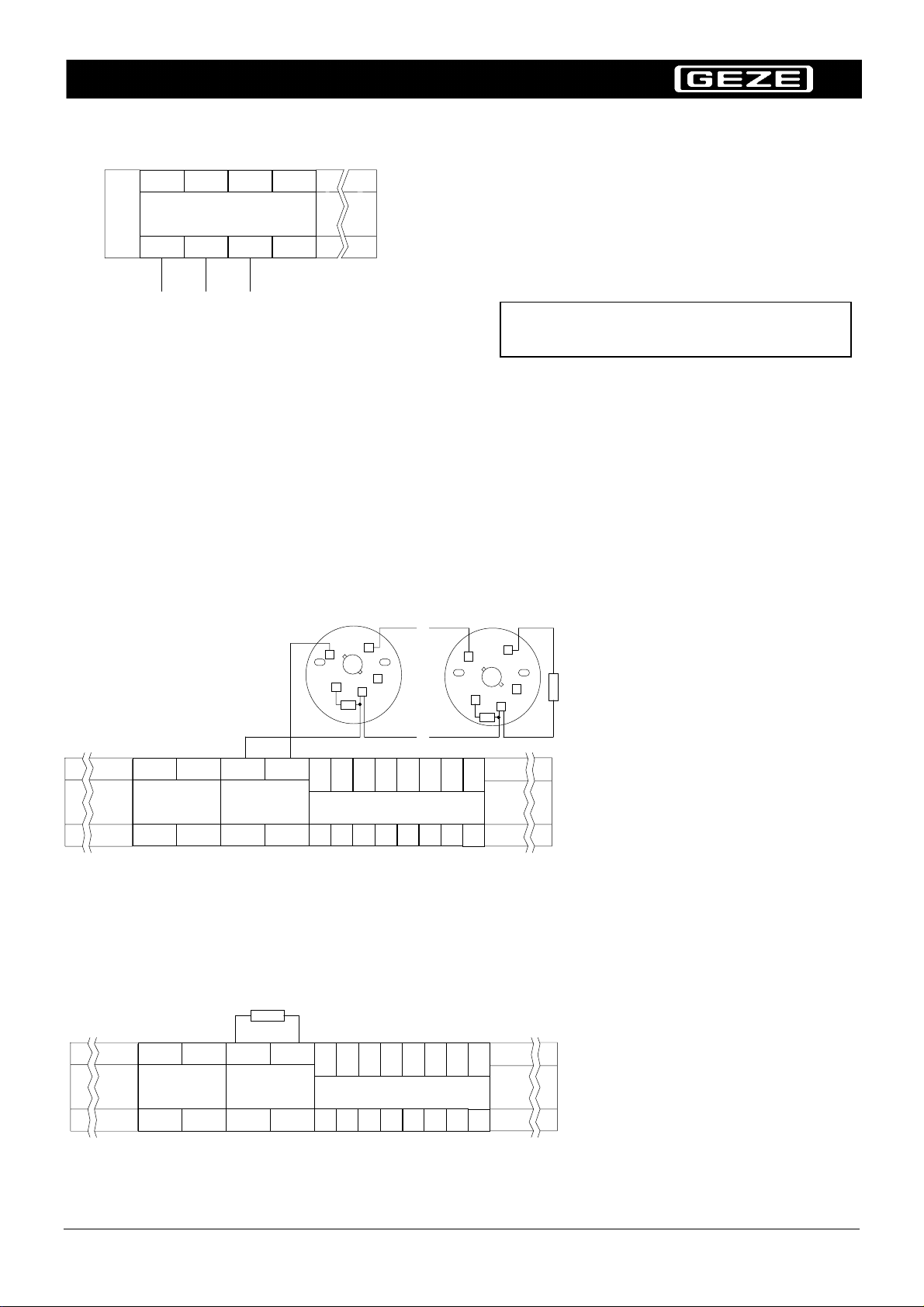

3.1 Mains connection ...........................................................................................................................................................4

3.2 Connection of the battery ...........................................................................................................................................4

3.3 Connection of smoke and heat difference sensor...........................................................................................4

3.4 Operation without smoke or heat difference senosr.......................................................................................4

3.5 Connection of SHE switch FT4/24V DC - VdS....................................................................................................5

3.6 Connection of fire alarm system (BMS) / remote trip release .....................................................................5

3.7 Operation without central fire alarm system (BMS) / remote trip release.............................................5

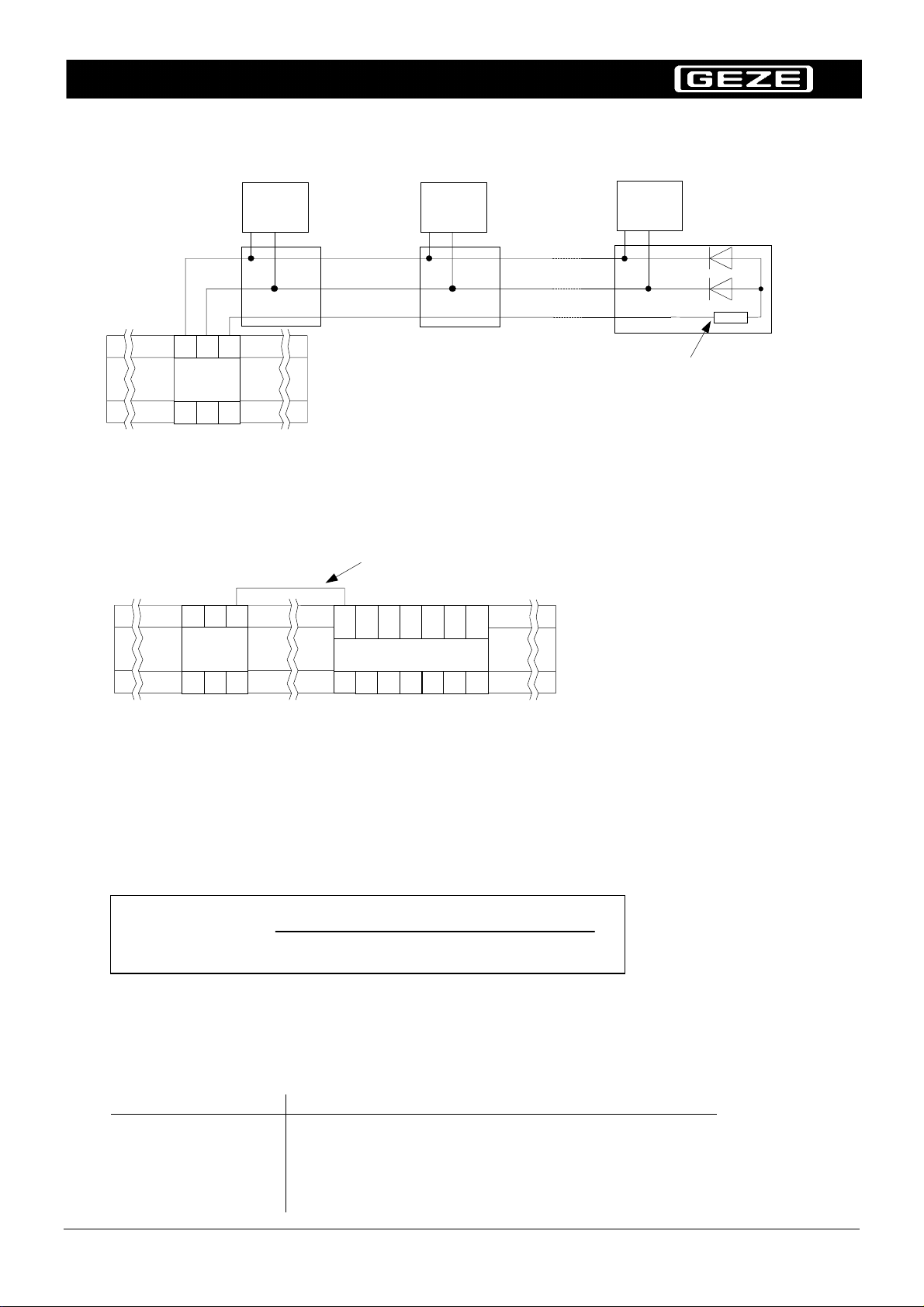

4.1 Connection of motors...................................................................................................................................................6

4.1.1 Linear, 1 cable section..............................................................................................................................................6

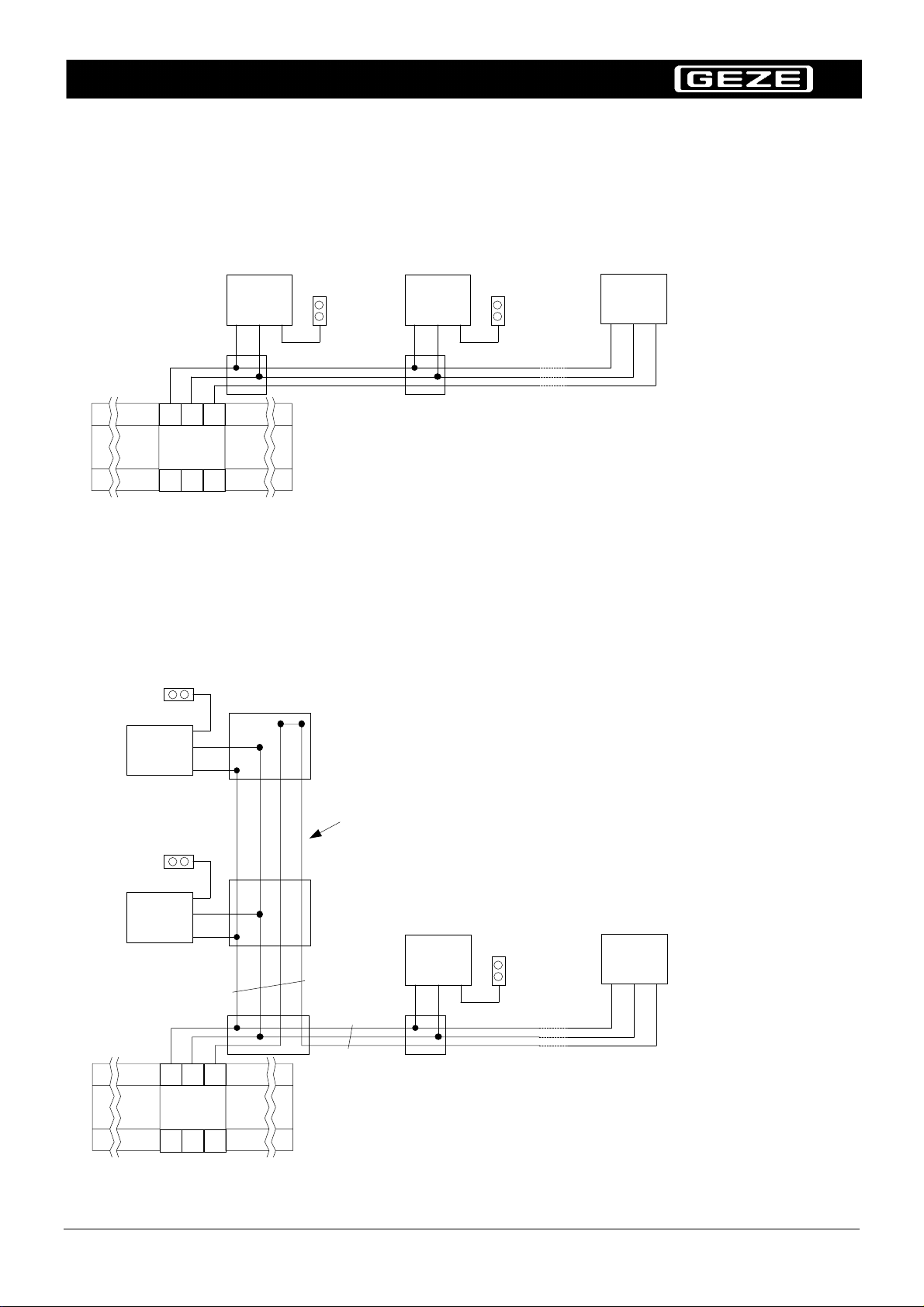

4.1.2 Branched, 2 or more cable sections...................................................................................................................6

4.1.3 Connections of motors without integrated line monitoring.....................................................................7

4.1.4 Unused motor group..................................................................................................................................................7

4.2 Motor lines.........................................................................................................................................................................7

4.2.1 Calculation of the cross-sections for motor lines........................................................................................7

4.2.2 Examples for max. line lengths in [m]................................................................................................................7

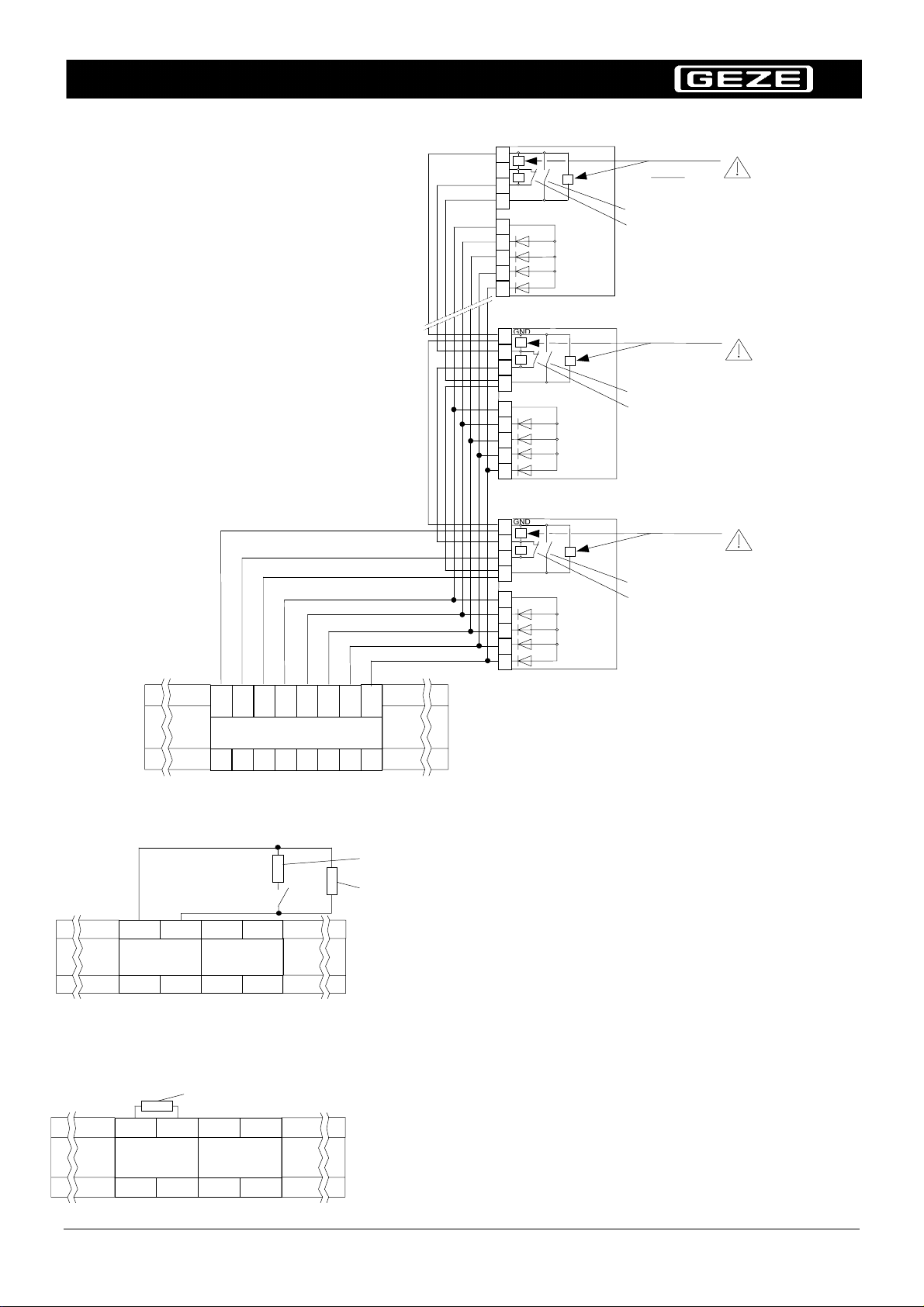

5.1 Connection of ventilator switch...............................................................................................................................8

5.2 Connection of several ventilator switches per ventilator group................................................................9

5.2.1 Ventilator switch LTA-230.......................................................................................................................................9

6 Connection of timer.........................................................................................................................................................10

6.1 Timer per ventilator group........................................................................................................................................10

6.2. Several ventilator groups with 1 timer...............................................................................................................10

7.1 Connection of rain/wind control unit ...................................................................................................................11

7.2 Connection of several emergency power control units E260N to 1 rain/wind control unit..........11

8.1 Potential-free signaling contacts (optional)......................................................................................................12

8.2 Connection with externals supply voltage........................................................................................................12

8.3 Connection of a sounder with internal supply voltage (max.30mA)......................................................12

Refer to cable layout 37101-9-0951

Observe the corresponding operating instructions!

118533-4 Connection Schema Emergency Power Supply System E260 N2/1 to N12/2-24V DC