GGM gastro NKJ4 User manual

Noodle Cooker

User manual

Safety precautions:

The following safety precautions must be observed when using this

machine:

1. Please read the manual carefully before using the machine.

2. Please don’t share the same socket with other high-power electrical

appliance so as to avoid over power load or other hazards.

3. The surface of this machine is very hot when the machine is at work or

shortly after its being used, so please keep away from the hot part to

avoid any burn.

4. Be more careful when using this machine with any children beside!

Small children are prohibited from using this machine alone. It must be

placed at a location inaccessible to children.

5. This machine must not be used without being taken care of.

6. The power line must not contact any sharp articles or any surface of

high temperature so as to prevent it from being damaged.

7. The power line and plug shall be often examined to see if they are

damaged. In case of any damage to them, they shall be stopped from

being used, and must be repaired or replaced by a professional technician.

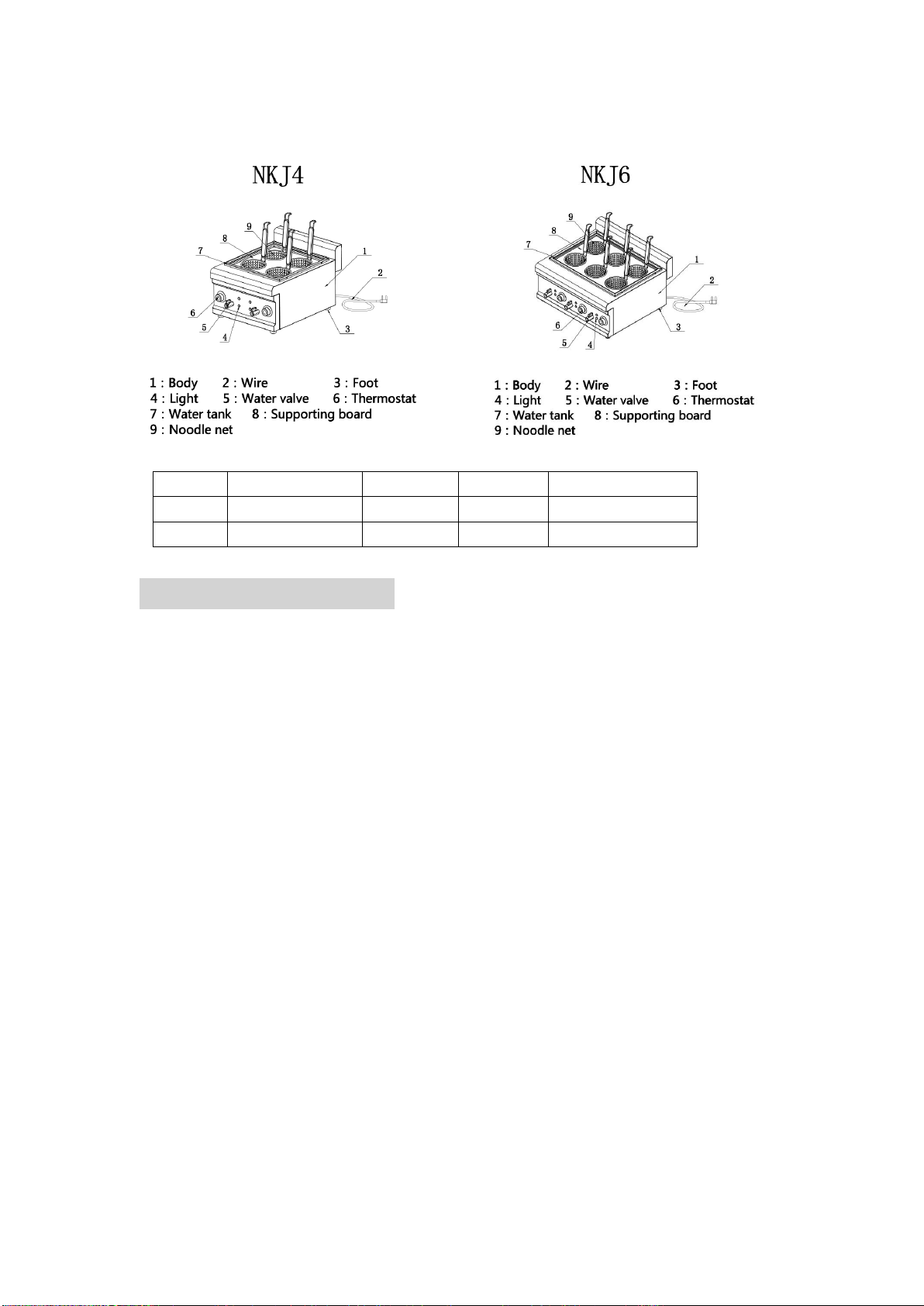

Model

Size(mm)

Voltage(V)

Power(w)

N.W.(KG)

NKJ4

565*420*345

230

3000

12.5KG

NKJ6

565*600*345

230

3000

15.5KG

8. Don’t damage, overly bend, draw or twist the power line. No heavy

article shall be placed on it and it must not be clamped.

9. Please turn the temperature controller to “0” and pull out the plug after

the machine is used so as to prevent any electric leakage or shock due to

the insulation aging.

10. This machine shall be placed at a dry, clean and well-ventilated place.

It must be placed horizontally and steadily.

11. The machine must be grounded reliably and the leakage switch shall

be properly installed to protect personal safety; otherwise, it must not be

used.

12. Please pull out the plug and wait until the machine cools down before

moving, inspecting or cleaning it.

13. Don’t insert or pull out the switch with a wet hand so as to avoid

electric shock hazard.

2

Notes for the first use

1. Please read the manual carefully.

2. Check if all switches are at the OFF position.

3. Check if the accessories are complete.

4. Please tear off the protective films on the surfaces of the machine and

brush away the anti-rust oil with a dry towel.

Notes

1. Transportation and storage

During the transportation, this machine must be handled with care, and

must not be placed upside down to prevent any damage to the cover or

internal part of the product. The packed hamburger machine shall not be

stored in the open air for a long time; instead, it shall be placed in a

warehouse with good ventilation but without corrosive gas. In case of

temporary storage, proper measures shall be adopted to protect it from

rains.

2. Notes for installation

1). The supply voltage must coincide with the service voltage of this

equipment.

2). Upon installation, we shall examine whether there is any looseness of

all connecting lines, whether the voltage is normal, and whether the

safety grounding is reliable.

3). This equipment shall be placed in a steady place, with 10cm away

from any incombustible matters on both sides, while its back shall be

20cm or farther from any incombustible matters, such as wall bricks or

windows.

4). The fixed wiring connecting with this equipment must be equipped

with an all-pole disconnection switch as per the rule of wiring, and each

pole on the switch shall have a contact separation of at least 3mm. It is

suggested that an earth leakage circuit breaker should be grounded. No

sundries shall be piled in front of the switch to ensure the convenient

operation of the switch.

5). No flammable and explosive articles are allowed to be stored near the

location of installation. The environmental temperature shall be lower

than 45℃, while the relative humidity below 85%.

6). The electrical connection, installation and reparation of this equipment

shall be operated by a professional technician.

Cleaning and maintenance

1. Before and after the hamburger machine is used, you must clean the

surfaces of the working table so as to prevent any oil stain or charred

chips left thereon.

2. Before such cleaning, you must shut off the power supply and stop

heating. You may do it after it cools down.

3. Upon completion of work every day, you can scrub the surfaces of the

machine and the power line with a wet towel which contains no corrosive

cleaner before cleaning it with a piece of dry cloth. No jet water course is

used for directly washing the machine so as to prevent any water from

permeating it and damaging its electrical performance, as well as any

accident in association with electricity. It is prohibited to scratch or

shovel the heating plate with a hard object.

4. The power switch must be turned off whenever the machine is not in

operation.

5. In case of not being in operation for a long period, the plate for

pancake must be cleaned and then placed in a warehouse with good

ventilation and without corrosive gas.

Breakdowns analysis and fixing

Fault phenomenon

Causes

Elimination methods

The heating indicator

light is on, but the

temperature does not

rise after the power is

switched on.

1. The temperature

controller has been

damaged;

2. The heat generating

line has been burnt out.

1. Replace the

temperature controller;

2. Replace the

damaged heat

generating line.

The heating indicator

light is on, but the

temperature rise

cannot be controlled

after switching on and

rotating the

temperature controller.

1. The temperature

controller fails.

1. Replace the

temperature controller.

The heating is normal,

but the indicator light

is not on after the

power is switched on.

1. The indicator light

has been damaged.

1. Replace the

indicator light.

The indicator light is

not on, nor does it

produce any heat.

1. The power supply is

abnormal, or the power

has not switched on.

2. The fuse has been

burned out.

1. Check the power

supply and the

connecting lines to see

if the power supply is

normal.

2. Replace the fuse.

The breakdowns listed above are for reference only. In case of any

breakdown, the machine shall be stopped from being used, and a prompt

notice shall be dispatched to the professional technician for inspecting

and repairing the machine!!!

NKJ4

NKJ6

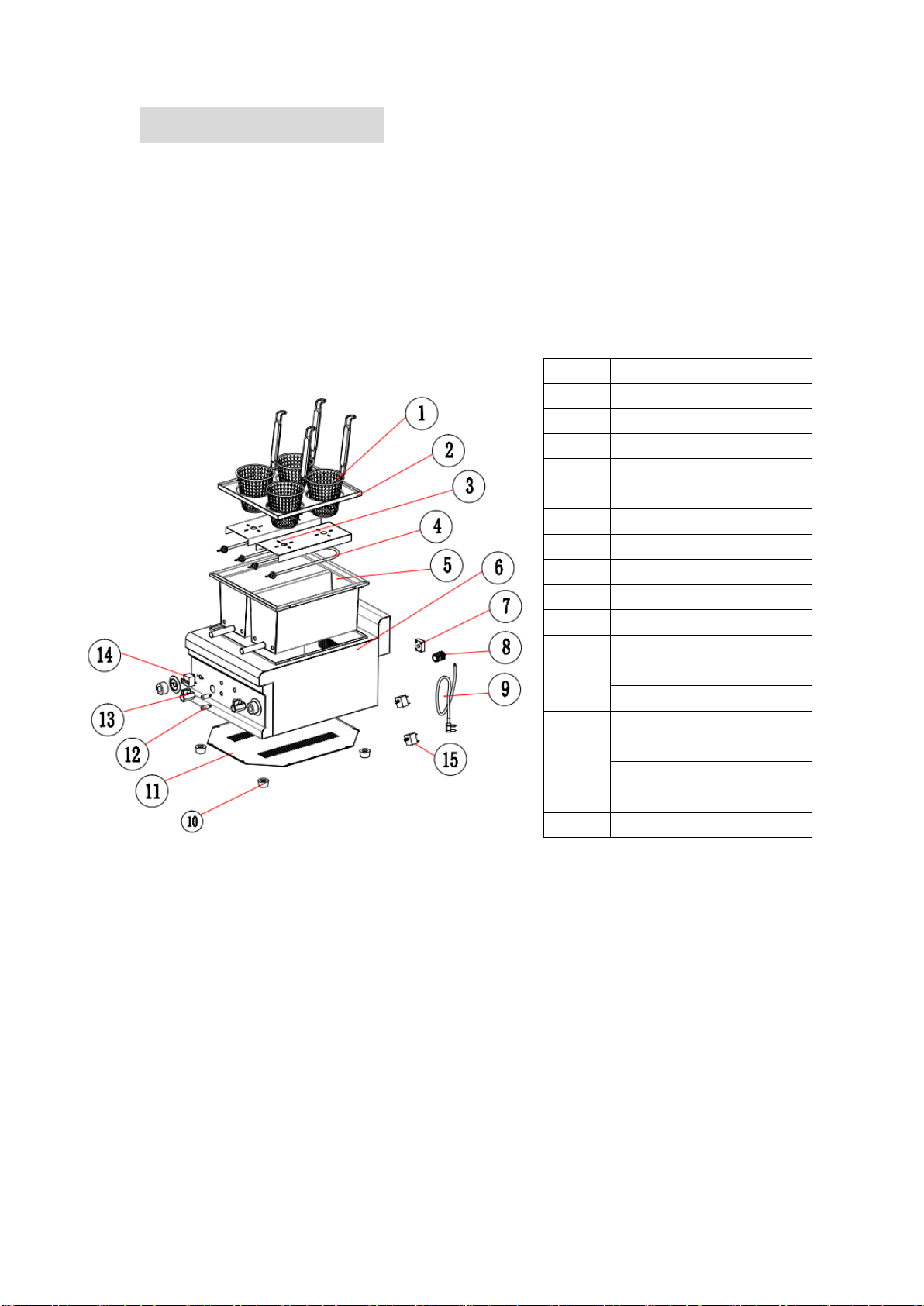

Exploded drawing

NKJ4

No.

Spare parts name

1

Noodle net

2

Net stand board

3

Element cover

4

Element

5

Water tank

6

Body

7

Connection terminal

8

Line clamp

9

Wire

10

Foot

11

Bottom sealing board

12

Light(Orange)

Light (Green)

13

Water valve

14

knob

negative

Thermostat

15

Temperature limiter

NKJ6

No.

Spare parts name

1

Noodle net

2

Net stand board

3

Element cover

4

Element

5

Water tank

6

Body

7

Connection terminal

8

Line clamp

9

Wire

10

Foot

11

Bottom sealing board

12

knob

negative

Thermostat

13

Light(Orange)

Light (Green)

14

Water valve

15

Temperature limiter

This manual suits for next models

1

Table of contents

Other GGM gastro Cooker manuals