H84.0.14.6C-03 Operating manual GMH 5690 Page 2 of 18

_____________________________________________________ _____________________________________________________________________________

Contents

1SAFETY......................................................................................................................................................................3

1.1 GENERAL NOTE......................................................................................................................................................3

1.2 INTENDED USE.......................................................................................................................................................3

1.3 QUALIFIED STAFF ..................................................................................................................................................3

1.4 SAFETY SIGNS AND SYMBOLS................................................................................................................................3

1.5 REASONABLY FORESEEABLE MISUSE ....................................................................................................................4

1.6 SAFETY GUIDELINES..............................................................................................................................................4

2PRODUCT DESCRIPTION......................................................................................................................................4

2.1 SCOPE OF SUPPLY ..................................................................................................................................................4

2.2 OPERATION AND MAINTENANCE ADVICE..............................................................................................................5

3START OF OPERATION.........................................................................................................................................5

4OPERATION..............................................................................................................................................................5

4.1 DISPLAY ELEMENTS...............................................................................................................................................5

4.2 PUSHBUTTONS.......................................................................................................................................................6

4.3 CONNECTIONS .......................................................................................................................................................6

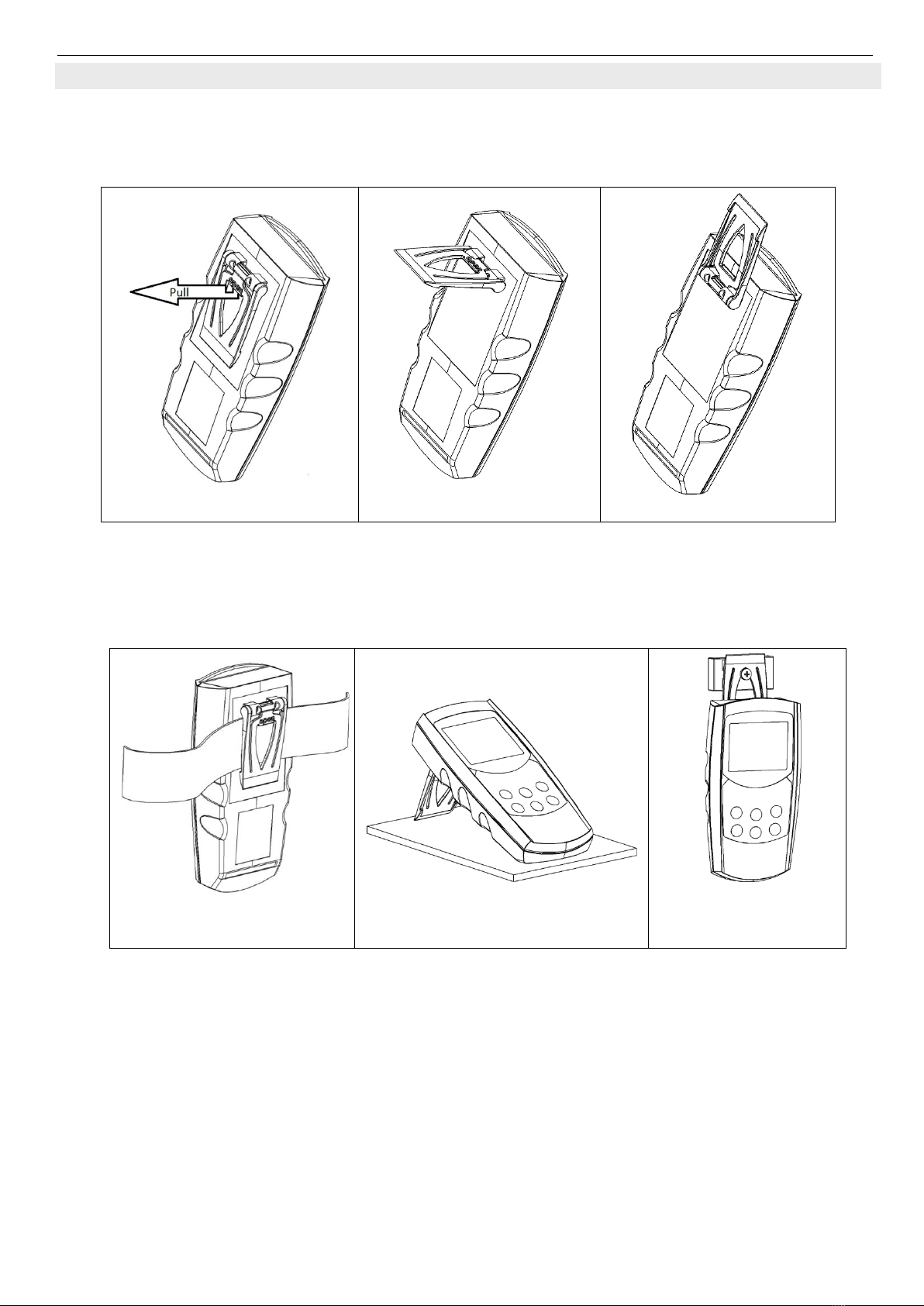

4.4 POP-UP CLIP...........................................................................................................................................................7

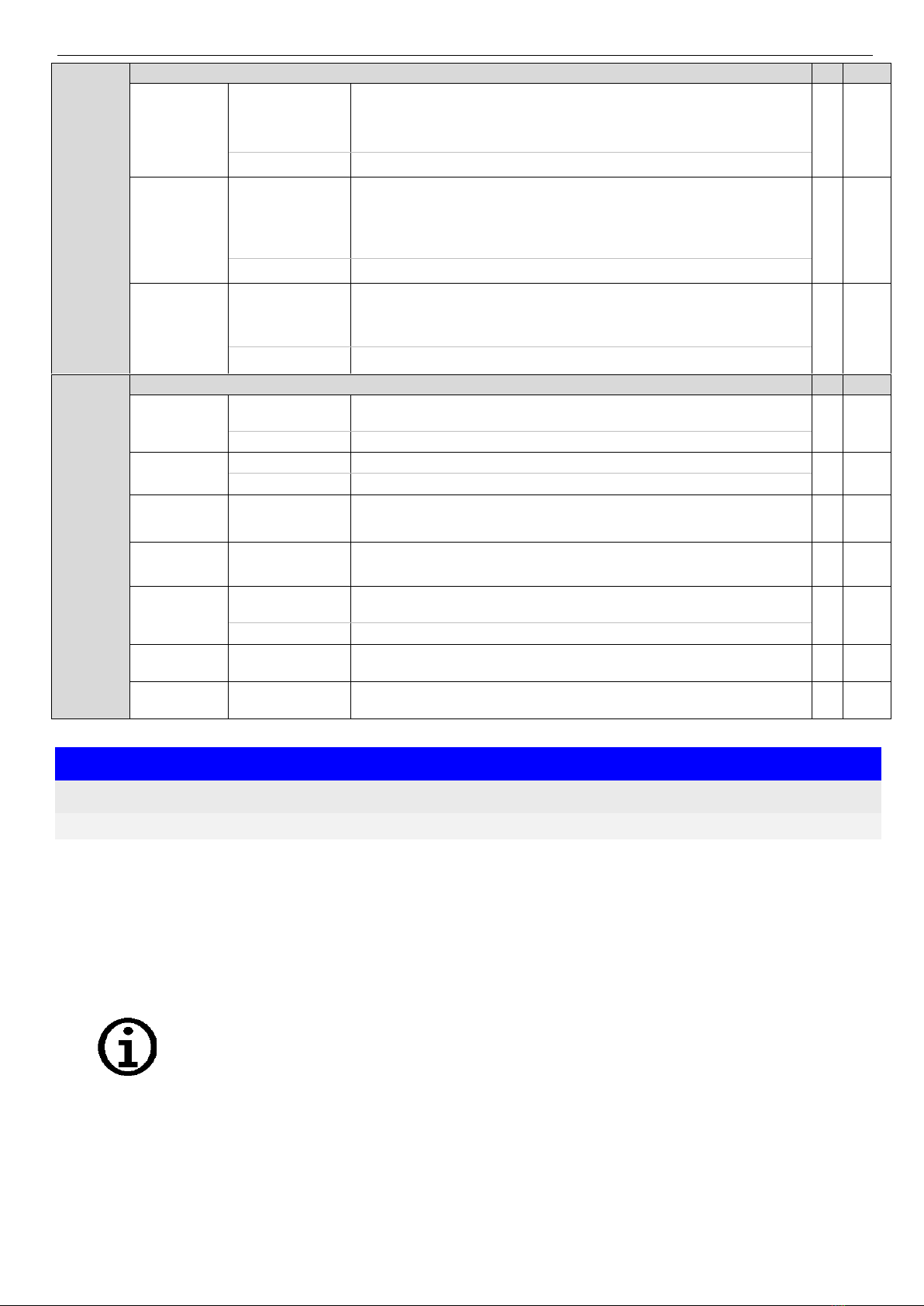

5CONFIGURATION...................................................................................................................................................8

6THE OXYGEN SENSOR..........................................................................................................................................9

6.1 GENERAL NOTES ABOUT THE OXYGEN SENSOR.....................................................................................................9

6.1.1 Life time .........................................................................................................................................................9

6.1.2 Mounting /operation position.......................................................................................................................10

6.1.3 Measuring precision ....................................................................................................................................10

6.2 SENSOR ELEMENTS..............................................................................................................................................10

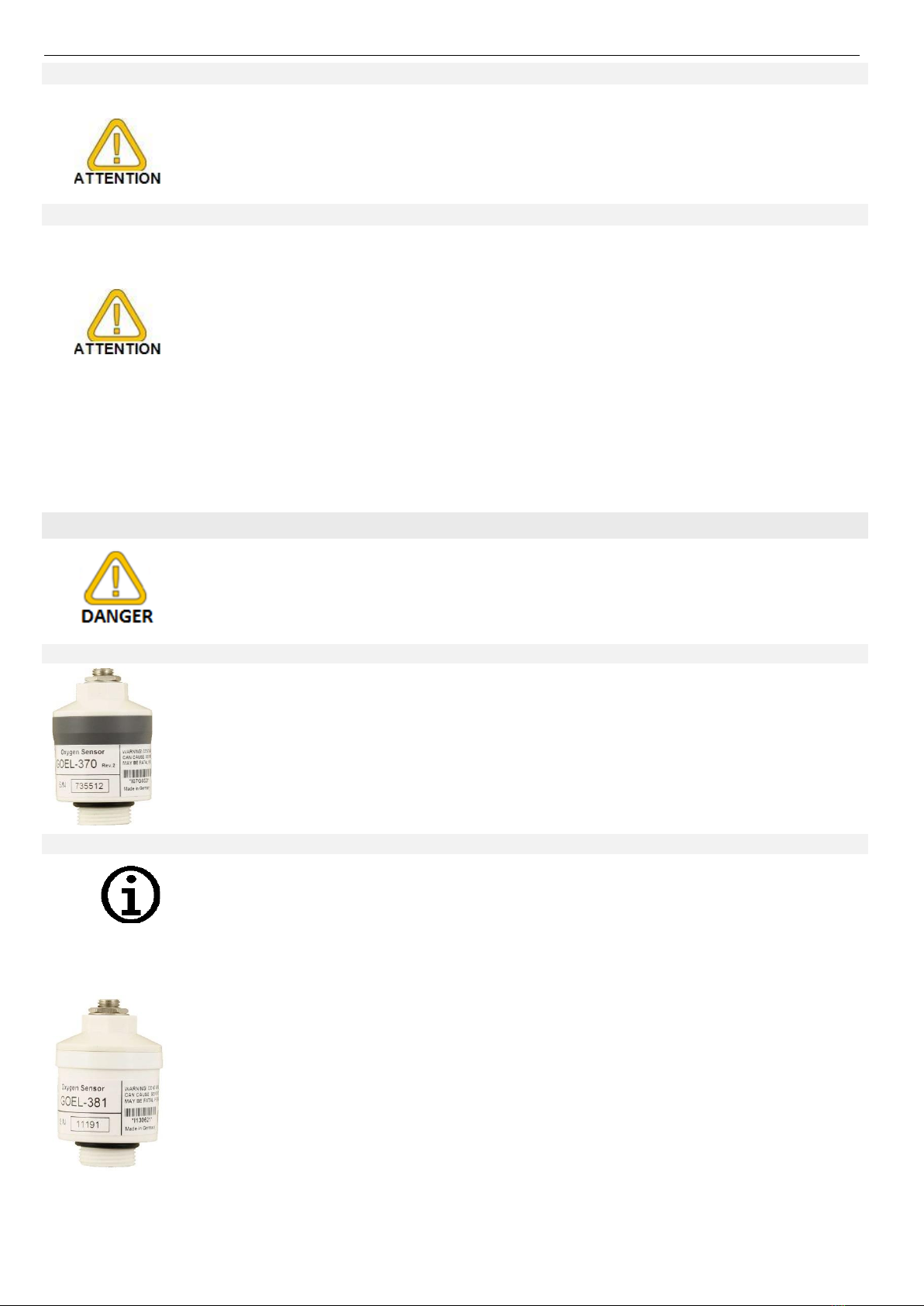

6.2.1 GOEL 370 acidic electrolyte........................................................................................................................10

6.2.2 GOEL 381 basic electrolyte.........................................................................................................................10

7OXYGEN MEASURING IN GASES- PLEASE NOTE.......................................................................................11

7.1 APPLICATION OF THE DIFFERENT SENSOR TYPES ................................................................................................11

7.1.1 GGO housing (closed sensor)......................................................................................................................11

7.1.2 GOO housing (open sensor) ........................................................................................................................11

8EXCHANGING THE SENSOR ELEMENT.........................................................................................................11

9CALIBRATION OF THE OXYGEN SENSOR....................................................................................................12

9.1 ONE POINT CALIBRATION “(AL. 1-PT“.................................................................................................................12

9.2 2/3- POINT CALIBRATION ”(AL 2-PT“,”(AL 3-PT“..........................................................................................12

9.3 EVALUATION OF SENSOR STATE “ELE[“..............................................................................................................13

9.4 CALIBRATION/ADJUSTMENT INTERVAL “[INT“...................................................................................................13

10 ADJUSTMENT OF TEMPERATURE INPUT.................................................................................................13

11 ALARM “AL.“........................................................................................................................................................13

12 UNIVERSAL OUTPUT .......................................................................................................................................14

12.1 INTERFACE.......................................................................................................................................................14

12.1.1 Supported interface-functions:.....................................................................................................................14

13 INSPECTION OF THE ACCURACY/ ADJUSTMENTS AERVICES ..........................................................15

14 BATTERY CHANGE...........................................................................................................................................15

15 ERROR AND SYSTEM MESSAGES................................................................................................................16

16 RESHIPMENT AND DISPOSAL.......................................................................................................................17

16.1 RESHIPMENT ....................................................................................................................................................17

16.2 DISPOSAL.........................................................................................................................................................17

17 SPECIFICATION.................................................................................................................................................17