S01.0.0X.6C-19 Installation and Operating Manual GEWAS 191 AN / N page 4 of 6

5 Installation and commissioning

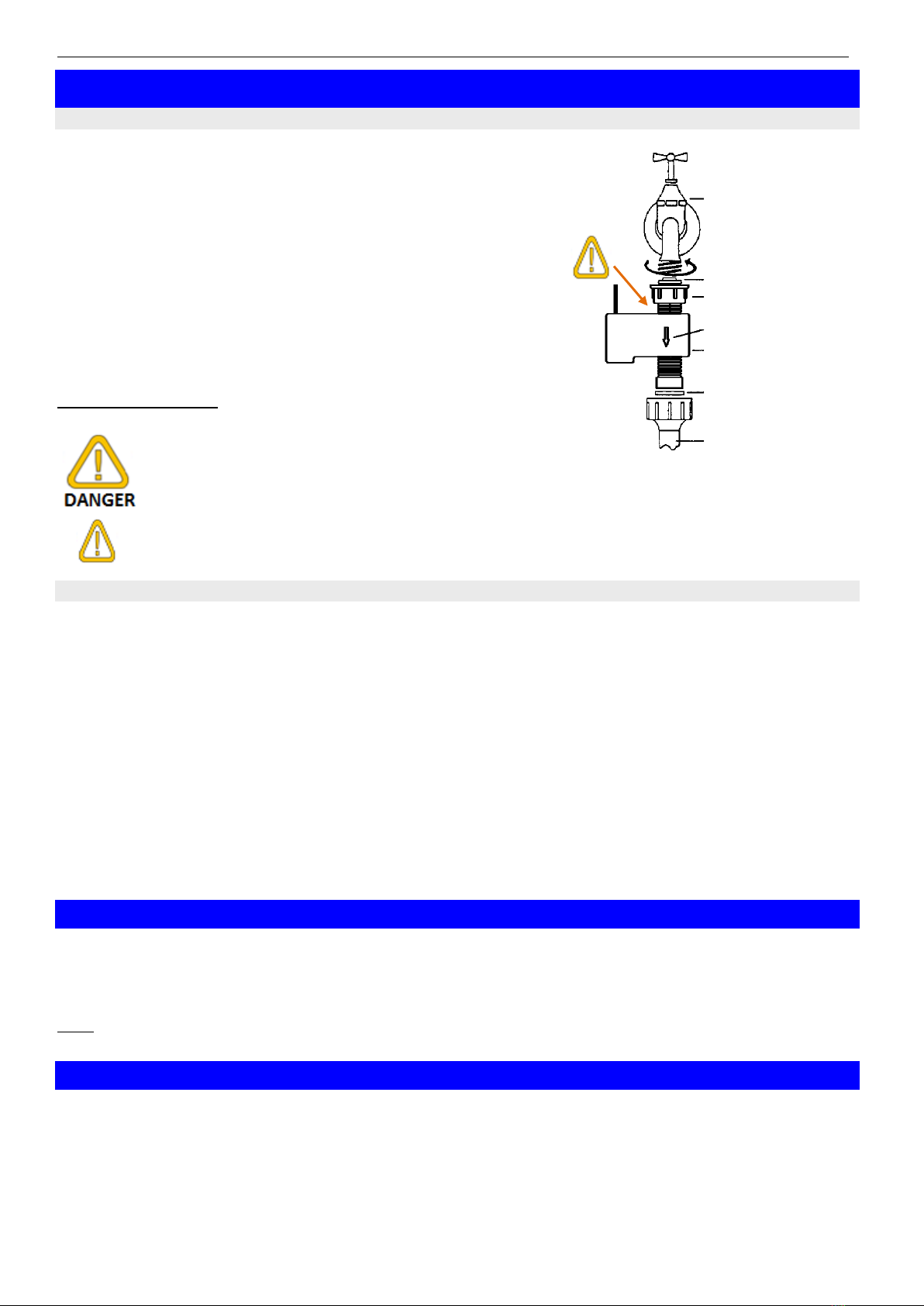

5.1 Installation of the solenoid valve

- Lock water feed lines.

- Insert sieve sealing ring.

Please take care having clean sealing surfaces.

- Connect solenoid with sleeve nut to the water feed by means of a

right-hand turn.

- Check leak tightness by turning on the water supply.

In case of leakage repeat the process above.

- Screw water connection tube onto the outlet of the solenoid valve

(use sealing ring or make sure that the tube itself is properly

sealed! ).

If the installation has been carried out correctly the sleeve nut can be

tightened by hand. In case of leakage check if sealing has been inserted

and if all sealing surfaces are clean; also check if the installation has been

carried out correctly. If necessary repeat installation process.

Hint for commissioning: The solenoid will not be opened unless it has

been connected to the activated control device.

Please ensure that the connection to the water feed are

completely tight !!

A water leakage on this position can´t be stoped by the

solenoid!

Do not apply turning force at housing, while mounted at tap - upper valve connection could be

unscrewed and therefore getting untight !

5.2 Installation of the control unit and the water sensor

- Make a rule to read the operating and maintenance advices before starting up the device.

- Place water sensor at desired position and fix it, if necessary.

Note: Choose best position for the water sensor, that both metal electrodes come into contact with water

as early and reliable as possible! (Keep an eye on floor unevenness).Protect against unintended shifting, e.g.

by using a screw or mounting tape.

- Please take care that the sensor electrodes do not touch any metallic surfaces, this may cause errors.

- Connect water sensor to the control unit.

- Open water feed line unless you have already done so.

- Plug in control device into a socket outlet with earthing contact.

=> Device is now active, the solenoid is open.

- Check water connection tubes for leakage.

- Connect device which is to be switched off in case of alarm to the socket outlet with earthing contact of the

control device.

! Well done, your GEWAS device is now ready for use !

6 Function

If the water film at the water sensor exceeds 0.5 mm the control device automatically triggers an audible alarm and

switches off the solenoid.

The GEWAS 191 AN also switches off the device connected to the control device.

To remove the alarm disconnect control device for a short time.

Note: The alarm will also be activated if the water sensor has been disconnected.

7 Alarm und operating signals

audible alarm at 1s interval: alarm condition

audible alarm, short signal every 10s: solenoid is not connected or defective

solenoid continuously switches on and of insufficient power supply

audible alarm at 2.5s interval insufficient power supply.