Z11.0.0X.6C-23 Operating manual GGO -, GGA -, GOO -, GOG - page 2 of 8

Contents

1. SAFETY ....................................................................................................................................................... 2

1.1. General note............................................................................................................................................ 2

1.2. Intended use............................................................................................................................................ 2

1.3. Skilled personnel..................................................................................................................................... 3

1.4. Safety signs and symbols........................................................................................................................ 3

1.5. Safety guidelines..................................................................................................................................... 3

2. PRODUCT DESCRIPTION....................................................................................................................... 4

2.1. Scope of supply....................................................................................................................................... 4

2.2. General information about application areas.......................................................................................... 4

2.3. General information about the oxygen sensors....................................................................................... 5

3. APPLICATION OF THE DIFFERENT SENSOR TYPES .................................................................... 6

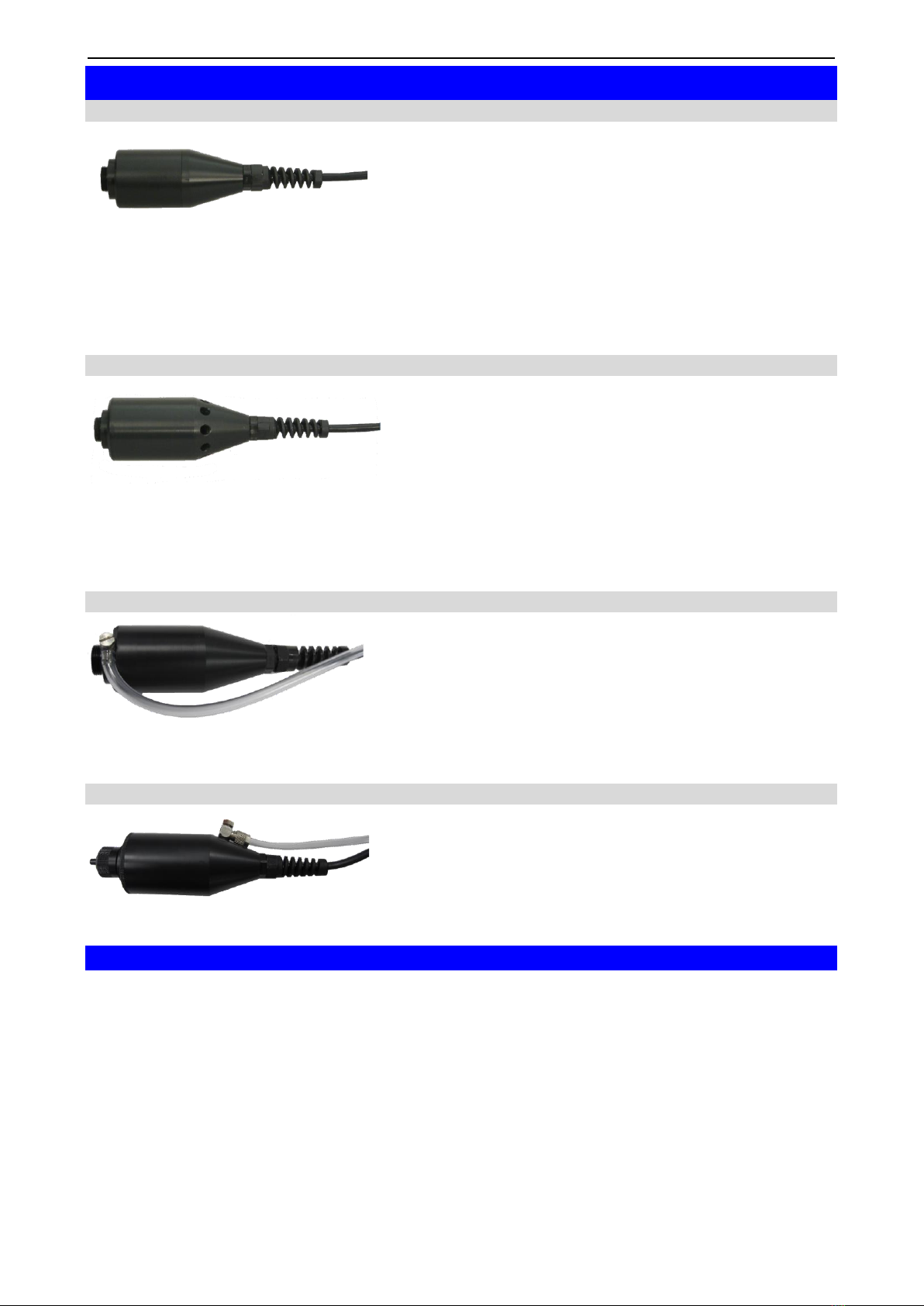

3.1. GGO housing (closed sensor)................................................................................................................. 6

3.2. GOO housing (open sensor).................................................................................................................... 6

3.3. GGA housing (closed sensor with pressure connection) ........................................................................ 6

3.4. GOG housing (ResOx Measuring).......................................................................................................... 6

4. MEASURING OXYGEN WITH THE GMH 369X AND GMH 569X................................................... 6

5. HOW TO OPERATE.................................................................................................................................. 7

6. EXCHANGING THE SENSOR ELEMENT............................................................................................ 7

7. DECOMMISSIONING, RESHIPMENT AND DISPOSAL.................................................................... 7

7.1. Decommissioning ................................................................................................................................... 7

7.2. Reshipment and disposal......................................................................................................................... 7

8. SPECIFICATION ....................................................................................................................................... 8

1. Safety

1.1. General note

Read this document carefully and get used to the operation of the product before you use it.

Keep this document within easy reach near the product for consulting in case of doubt.

Mounting, start-up, operating, maintenance and removing from operation must be done by quali-

fied, specially trained staff that have carefully read and understood this manual before starting any

work.

The manufacturer will assume no liability or warranty in case of usage for other purpose than the

intended one, ignoring advices of this manual, operating by unqualified staff as well as unauthor-

ized modifications to the product.

1.2. Intended use

The product is suitable for the measuring of gaseous oxygen, in conjunction with appropriate de-

vices.

Dependent on the application, a suitable sensor-element must be chosen.

See also the specification at the end of the document.

Personnel which starts up, operates and maintains the device has to have sufficient knowledge of

the measuring procedure and the meaning of the resulting measured values, this manual delivers a

valuable help for this. The instructions of the manual have to be understood, regarded and fol-

lowed.

To be sure that there´s no risk arising due to misinterpretation of measured values, the operator

must have further knowledge in case of doubt - the user is liable for any harm/damage resulting

from misinterpretation due to insufficient knowledge.