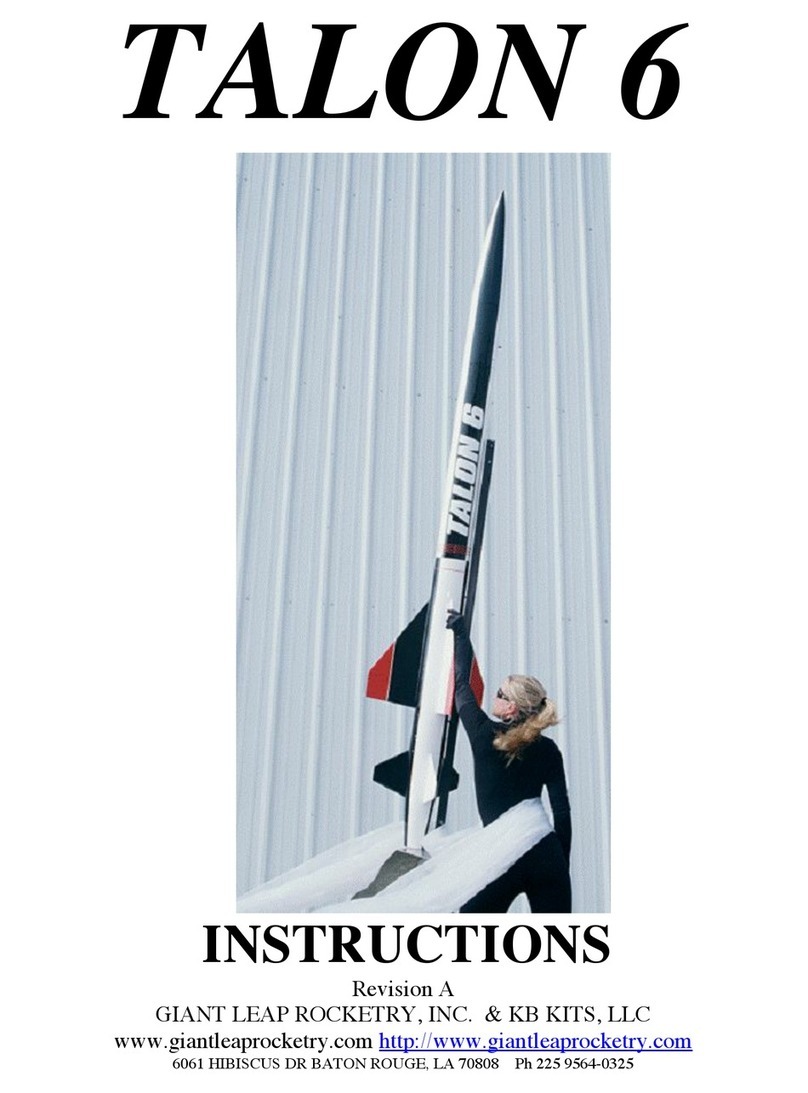

Specifications:

Dry Wt. Mass (no motor load) 198 oz. (Please

allow for slight variation in weight due to differ-

ence in epoxies and paint thickness).

Length: 92”

Outside Diameter O.D. 4.02”

Inside Diameter I.D. 3.9 ”

CP= 65” aft from nosecone tip

CG should be less than 57” aft of nosecone tip

Motor Mount: 54mm (29&38 mm with optional

54/38 mm adapter)

Recommended 38mm motors: Requires the

optional SLIMLINE 54/38mm adapter

Aerotech: H123, H148, H242, I161, I357,

I300, I211, I285, I284, 1366, I435, J420, J350,

J570

Pro38: H153 I205, I285, J285, J330

Recommended 54mm motors:

J90, J180, J275, J315, J415, J135, J800, J540,

J800, K1100, K695, K550, K695, K700

Pro54: J295, K445, K570, K660

WARNING!!

Flying rockets is potentially dangerous, and

you or others can be injured and/or killed by

the usage of this product. Property damage can

also occur by the usage of this product. In us-

ing this product, you agree to comply strictly

with all safety codes of the Tripoli Rocketry As-

sociation and the National Association of Rock-

etry, as well as all local, State and Federal laws.

By using the product, you agree that Giant

Leap Rocketry, LLC, (also in this document

noted as GLR) it’s owners or employees will

not be held legally or financially responsible

for the correct or incorrect usage of this prod-

uct. If you do not agree with these statements,

return the kit in resalable condition to Giant

Leap Rocketry for a refund. By using this kit,

you agree that you have read, understand and

accept these conditions.

PLEASE READ THE SAFETY CODE AND

LIABILITY STATEMENTS AT THE END

OF THESE INSTRUCTIONS.

NOTE: THIS ROCKET IS NOT A TOY

BECAUSE OF THE ROCKETS SIZE AND

WEIGHT IT IS A SERIOUS VIOLATION

OF FEDERAL LAW TO FLY THIS

ROCKET ANYWHERE EXCEPT AT

LAUNCHES SANCTIONED BY THE TRIP-

OLI ROCKETRY ASSOCIATION OR THE

NATIONAL ASSOCIATION OF ROCK-

ETRY WHOSE ORGANIZERS HAVE SE-

CURED AN APPROPRIATE WAIVER

FROM THE FEDERAL AVIATION ADMIN-

ISTRATION. FAILURE TO DO SO CAN

RESULT IN SUBSTANTIAL FINES AND/

OR IMPRISONMENT. DO NOT EVEN

THINK OF FLYING THIS ROCKET ANY-

W H E R E E X C E P T AT C E RT I F I E D

LAUNCHES.

3