2

20 minutes an hour, with the pump running with-out

pressure or turned o in between. For example, this

can be full load operation for 5 minutes four times an

hour with 10 minute breaks in between or continuous

full load operation for 20 minutes followed by a 40

minute break.

IMPORTANT! If higher medium temperatures or

liquids other than water are involved or aggressive

media such as seawater, demineralised water etc., the

pump must be tted with a separate cooling circuit.

The separate cooler must have a cooling eciency of

1700 watt. If there is a danger of frost, an appropriate

amount of antifreeze must be mixed into the cooling

circuit.

When starting up for work, the pump must run rst at

zero pressure for approximately 1 minute.

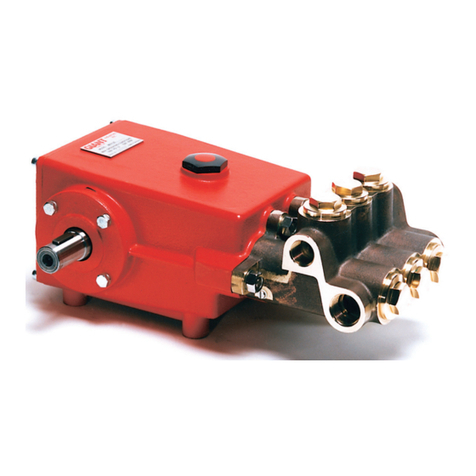

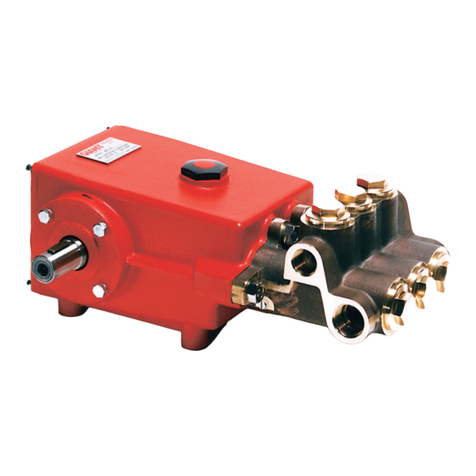

IMPORTANT! The GP8100 series has a black arrow

on the reduction gear which shows the preferred

direction of rotation. The pumps can be de-livered

either with the gear on the left side or right side which

eases the planning of assembling units with regard to

rotational direction.

Gear on right side from behind pump = optimal

rotation: to the left

Gear on left side from behind pump = optimal rotation:

to the right

The preferred/optimal direction of rotation ensures the

motion of the connecting rods correctly shovels the

oil on to the crosshead guides – which is a particular

advantage where continuous operation is involved.

The pump can also be run against the recommended

direction of rotation if operated periodically or at

reduced pressure. If so, the pump has to be run in

in this direction to smoothen the bearing areas. This

is done by a one-time operation at zero pressure for

at least 30 minutes; thereafter the pressure must be

slowly increased over the next hour to the desired

maximum operating pressure; the pump is then run in.

Check the oil temperature during this process.

IMPORTANT! The pump and cooling system must be

emptied if there is a danger of frost. Travel wind can

cause water in pumps tted on open vehicles to freeze

even if the outside temperature is above freezing

point.

To empty the cooling circuit, remove the L-joints (K11)

on the pump head (50). Blow out the circuit liquid at

the joint connection (K11/K7) using compressed air.

The torque tenson on the valve casing nuts (49A) is to

be checked after approximately 200 operating hours.

Please see the section ‘Maintenance’ concerning the

torque values.

The pump must be at zero pressure when checking

the torque tension.

IMPORTANT! The service life of the seals is

maximized if a minimal amount of leckage is present.

A few drops of water can drip from each plunger every

minute. Leakage has to be examined every day;

the plunger seals must be changed should leckage

become excessive (=constant dripping).

INSTALLATION INSTRUCTIONS

The stated gures are for maximum pressure

and maximum speed (rpm) and apply for interval

operation with cold water.

Required NPSH refers to water (specic weight 1kg/

dm3, viscosity 1°E) at maximum permissible pump

revolutions.

Fluid medium: Clean water ltered with 200μm.

*higher temperatures possible with separate

crankcase cooling system; the manufacturer is to be

contacted in this case.

Operation and Maintenance

Check oil level prior to starting and ensure trouble-

free water supply.

IMPORTANT! If there is a danger of frost,

the water in the pump and in the pump ttings

(particularly the unloader valve) must be emptied.

The second discharge port can also be used and the

pump run “dry” for 1-2 minutes for this purpose.

Oil amount: 4.2 gallons (16.0 litres). Only use ISO

VG 220 industrial gear oil (e.g. Aral Degol BG220)

or automobile gear oil SAE 90 GL4. Initial change

after 50 operating hours and then every 1000

operating hours after one year latest.

IMPORTANT! When operating in damp places

or with high temperature uctuations. Oil must be

changed immediately should condensate (frothy oil)

occur in the gear box.

NPSH values must be observed.

Cooling the Gear Oil

IMPORTANT! The water input pressure must not

exceed 29 PSI (2 bar) when using the integrated

system for cooling the gear oil (standard version).

If a separate cooling circuit (maximum 29 PSI [2

bar]) is installed, it is then possible to have an input

pressure of up to maximum 145 PSI (10 bar) on the

suction side of the pump.

Make sure that suction pulsation is suciently

dampened – water column resonance must be

avoided.

IMPORTANT! The pumps can be run without gear

oil cooling in continuous operation up to a power

rating of 93.9 HP (70 kW) or with major intermit-tent

operation at full performance.

If operational power exceeds 93.9 HP (70 kW) or if

continuous operation is the case, the pump must be

run with the integrated oil cooling system. The max.

temperature of the water being pumped and which is

also fed through the cooling system must not exceed

86 °F (30 °C). The water amount which is fed into

the cooling system depends on the pump speed and

is approximately 1.9 GPM (7.0 L/min) at 580 pump

rpm. The cooling water is sucked in by one of the

pumping chambers and pumped away.

Denition of intermittent operation: operation

at full performance for not more than altogether