6

8. Maintenance and Servicing

For the type of threadlocker used and the required

tightening torques, observe the table in the

exploded view.

8.1 Special tools required

The following special tools are required for

assembly:

- Fitting Sleeve (Tool-11)

- Pull-out tool size 2 (Ø20mm)

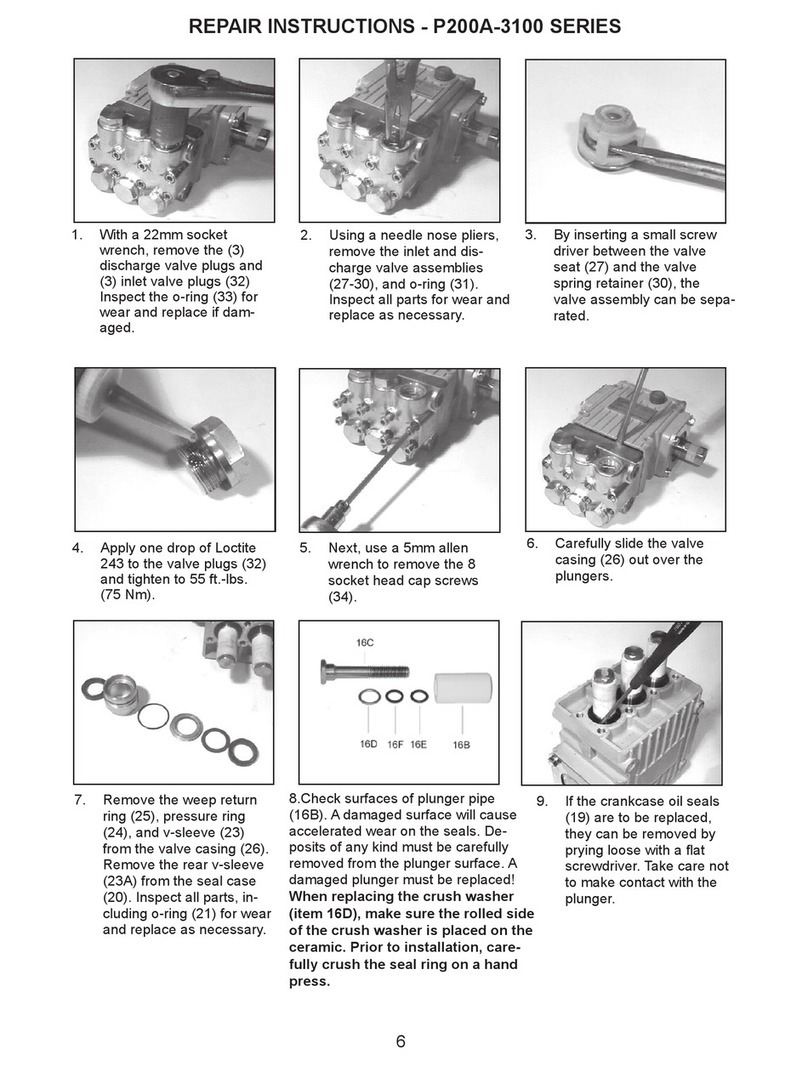

8.2 Suction and Discharge Valves

Screw out plugs (32) with a 12-point socket

wrench.

Check suction and discharge valves that are

under the plugs by taking out the valves with a

pair of at tongs and then taking them apart.

Examine valve plate (28) and valve seat (27).

Check O-rings (31/33) and replace if necessary.

Wet O-rings thinly with silicone grease or mineral

oil and insert carefully.

Tighten the plugs to the required torque.

Take care to reassemble in correct sequence.

8.3 Seals and Plunger pipe

Loosen screws (34) and remove valve casing (26)

by pulling it off over the plungers.

Remove seal adaptors (20) out of the valve casing

(26).

Remove drip-return ring (25), support ring (24),

grooved seal (23) and out of valve casing (26).

Remove grooved seal (23) out of seal adaptor

(20).

Wet new seals and O-rings thinly with silicone

grease or mineral oil and insert carefully.

Pay attention to the installation position of the

seals.

Check O-rings (21) and replace if necessary.

The grooved seal (23) or respectively

grooved seal pack (23) on the high-

pressure side is to be tted carefully into

the valve casing (26) using a tting

sleeve (Tool-11).

REPAIR INSTRUCTIONS - P435-5121 and P450-5121

Alternatively, the seal can also be carefully tted

into the valve casing using a screwdriver.

Under no circumstances must the seal surface in

the valve casing or the seal lip be damaged.

Check plunger surfaces (16).

Damaged surfaces cause hard wear on seals.

Lime deposits or similar on the plunger must be

removed.

Plunger surface must not be damaged in

the process.

In the case of lime deposits in the pump,

care must be taken that the drip-return

bores in parts (25) and (26) ensure trouble-free

drip-return.

If the plunger pipe (16B) is worn out, loosen

tension screw (16D) and remove together with

plunger pipe.

Check and clean contact surface on plunger (16A),

check oil scraper(16H), t new plunger pipe.

Cover thread of tension screw (16D) with a thin

coat of thread locker and tighten carefully to the

required torque.

Under no circumstances should thread-

locker get between the plunger pipe (16B)

and the centring neck on the plunger

(16A). Tensioning of the plunger pipe due

to eccentric tightening of the tensioning

screw or due to dirt or damage to the contact

surface can lead to breakage of the plunger pipe.

When assembling, tighten the screws (34) to the

required torque.

642 7

8135

If required, supplementary assembly

instructions can be requested from the

manufacturer Giant Industries, Inc.