1. General information ............................................................................................................................3

2. Safety guidelines ................................................................................................................................3

3. Maintenance ....................................................................................................................................... 3

4. Declaration of conformity ....................................................................................................................3

5. Boiler connection dimensions .............................................................................................................4

6. Key for code designation ....................................................................................................................4

7. Technical specifications......................................................................................................................4

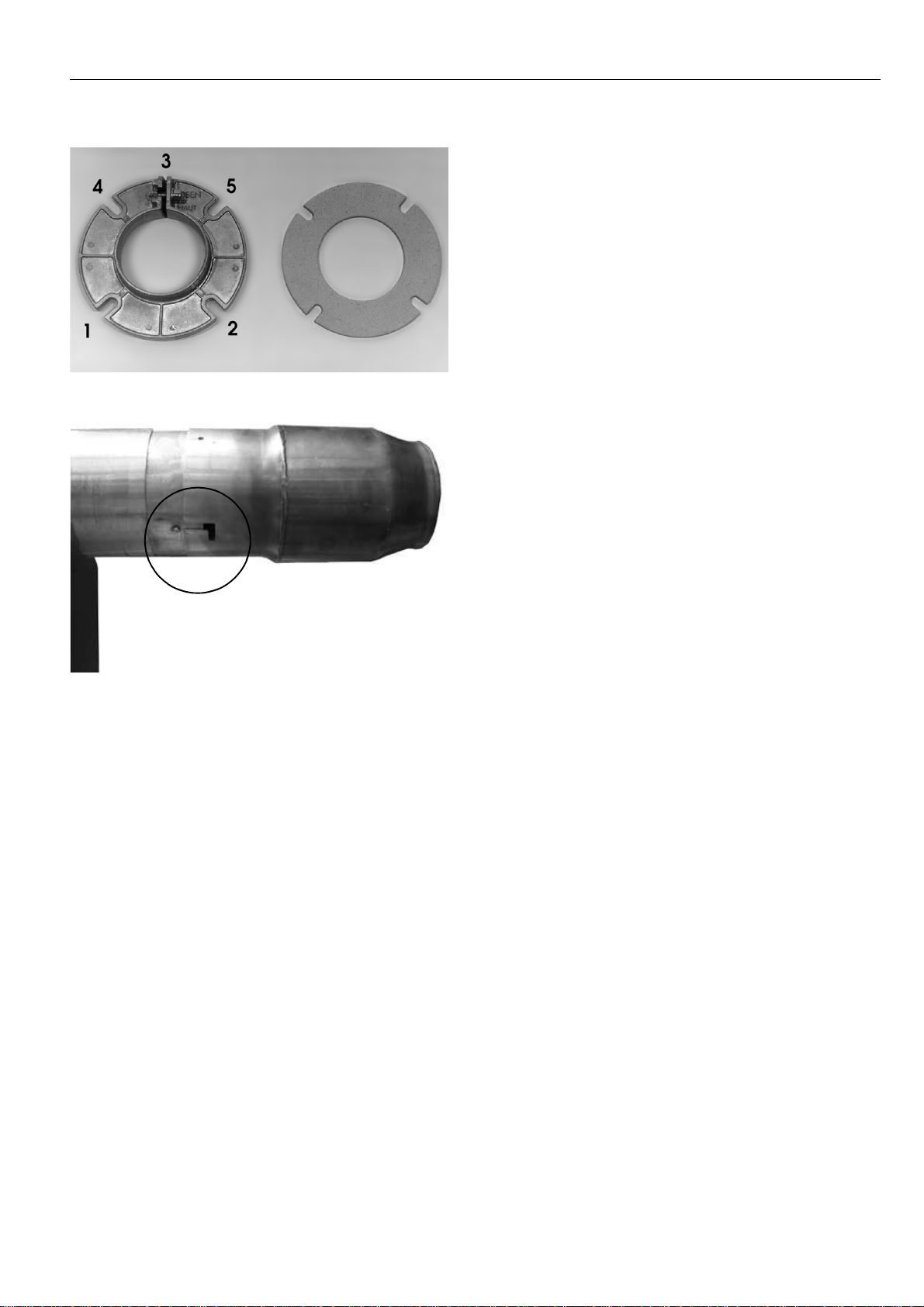

8. Installing flange and burner ................................................................................................................5

9. Connecting to power supply ...............................................................................................................6

10. Installing the oil line ............................................................................................................................7

11. Oil pump .............................................................................................................................................8

12. Checking the operation of the flame monitor control unit ...................................................................9

13. Setting the air flow rate.....................................................................................................................11

14. Actuator drive.................................................................................................................................... 12

15. Setting the ignition electrodes........................................................................................................... 12

16. Service position ................................................................................................................................13

17. Adjusting the inlet nozzle..................................................................................................................13

18. Notes about the mixing unit .............................................................................................................. 14

19. Nozzle replacement..........................................................................................................................14

20. Nozzle replacement..........................................................................................................................14

21. Start-up .............................................................................................................................................15

22. Calibration of the boiler-burner ......................................................................................................... 15

23. Flue connection ................................................................................................................................15

24. Exhaust gas thermometer................................................................................................................. 15

25. Circuit diagram ................................................................................................................................. 16

26. Troubleshooting ................................................................................................................................ 17

27. Adjustment table ...............................................................................................................................18

28. Explosion drawings / spare parts lists............................................................................................... 20

29. Dimensions.......................................................................................................................................26

30. Working ranges................................................................................................................................. 26