Guidelines/ Manual

BTS256-LEDTester/ Page6

AboutLEDMeasurement

Version 01.2009-01

Picture6.1:

WhiteLEDAssembled toDUTPCBofGigahertz-Optik’s

LEDA2LEDMeasurementAdaptersimulating Application

ConditionsDuring Qualification Measurement

TheBTS256-LEDtesterisalightmeasurementdevicees-

peciallydesignedtoanalyzethelightoutputofprintedcir-

cuitboard(PCB)mountedand operatedLightEmitting Di-

odes(LED).

Basics ofLEDMeasurements:

LEDs aresemiconductorlight sourceswithahigh efficiency

electricalpowertolightpowerconversion.Aswithany

semiconductordevice,operating temperatureeffects

changesinperformancereferredtoasadevice’stempera-

turecoefficient. Inconnection withLEDsthetemperature

coefficientwilleffectareduction inlightoutputand adriftin

color.Operation underhigh junction temperatureconditions

mayeffectlifetime.Certainambientoperating environ-

ments,e.g.high humidity,canimpactlifetimeand device

specificationsaswell.Thermalmanagementisofprimary

importancetothesuccessfulimplementation of LEDs.

Sorting orgrading ofindividualLEDsbycolordifferences

caused bytolerancesinthe semiconductorprocessisa

common practiceoffered bymostsemiconductormanufac-

turers. But duetodiffering LEDmanufacturer’ssorting proc-

essesandoperating conditions,the LEDprocessing indus-

tryacceptstheneedforin-housemeasurements.These

measurementsshouldbe made withthe LEDdeviceinits

actualoperating stateintheapplication.

The mostcommon lightmeasurementquantity usedin

LEDtesting isluminousfluxmeasuredinlumen.Thisquan-

titycorrespondstoLEDefficiency bycorrelation ofthetotal

light outputtotheelectricalpower.Measurementofthe total

lightoutputinlminstead ofluminousintensityincdpro-

ducesmuchbetterreproducibilitybecauseitisindependent

ofspatiallightdistribution (picture6.2)whichmaybe influ-

encedbytemperature,humidity,distance,differentviewing

angles, misalignment and otherexperimentalerror.

Measurementofluminousfluxwitha goniometricpho-

tometer isthe mostprecisemethodofmeasurement. Here

asummation ofthe spatialluminousintensitydistribution

withinthehemisphereinfrontoftheLEDisperformed.

Howeverthisisatimeand costintensivemethodtypically

applied inhigh levelR&Dand Qualitylaboratories.

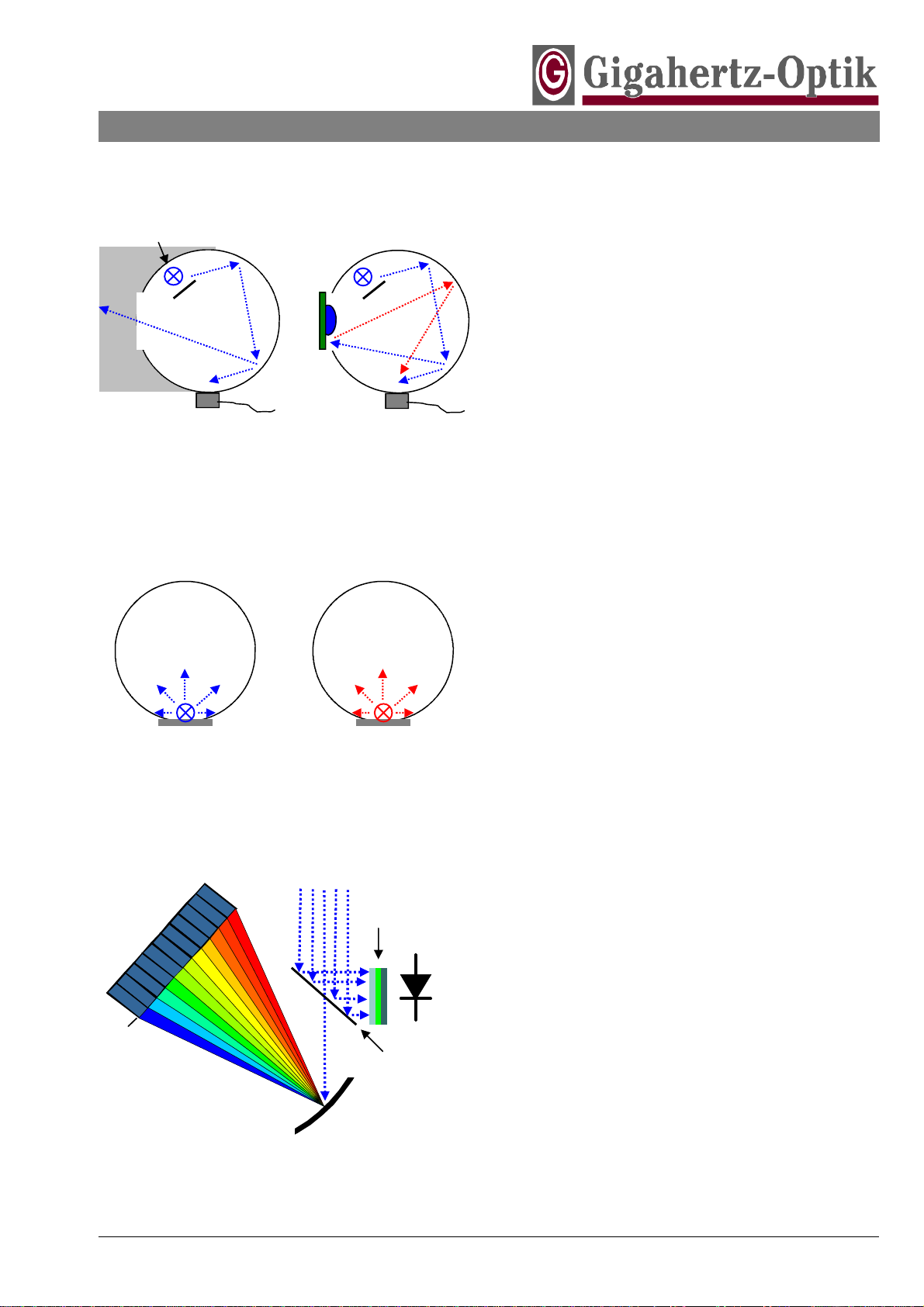

Inindustryalight meterwithan integratingsphere (picture

6.3)arethemostcommon measurementdevicesem-

ployed.Thisapproachofferseasyand fastoperation as

wellascosteffectiveness.Theintegrating sphereactsas

lightintegratorforspatiallyemitting lightsources.The inte-

gration effectistheresultofmultiplediffusereflectionsof

the lighton the diffusereflecting surfaceofthehollow

spherewhichresultsinauniformlightdistribution atthe

spheresurface.Theilluminancemeasuredatanyposition

on theintegrating spheresurfaceisthereforean indicatorof

the totalfluxgenerated byalight sourceinside oroutside of

the sphere. Aswithanyothermeasurement deviceintegrat-

ing spheresexhibitsome typicalcharacteristics which

must beconsidered inuse:

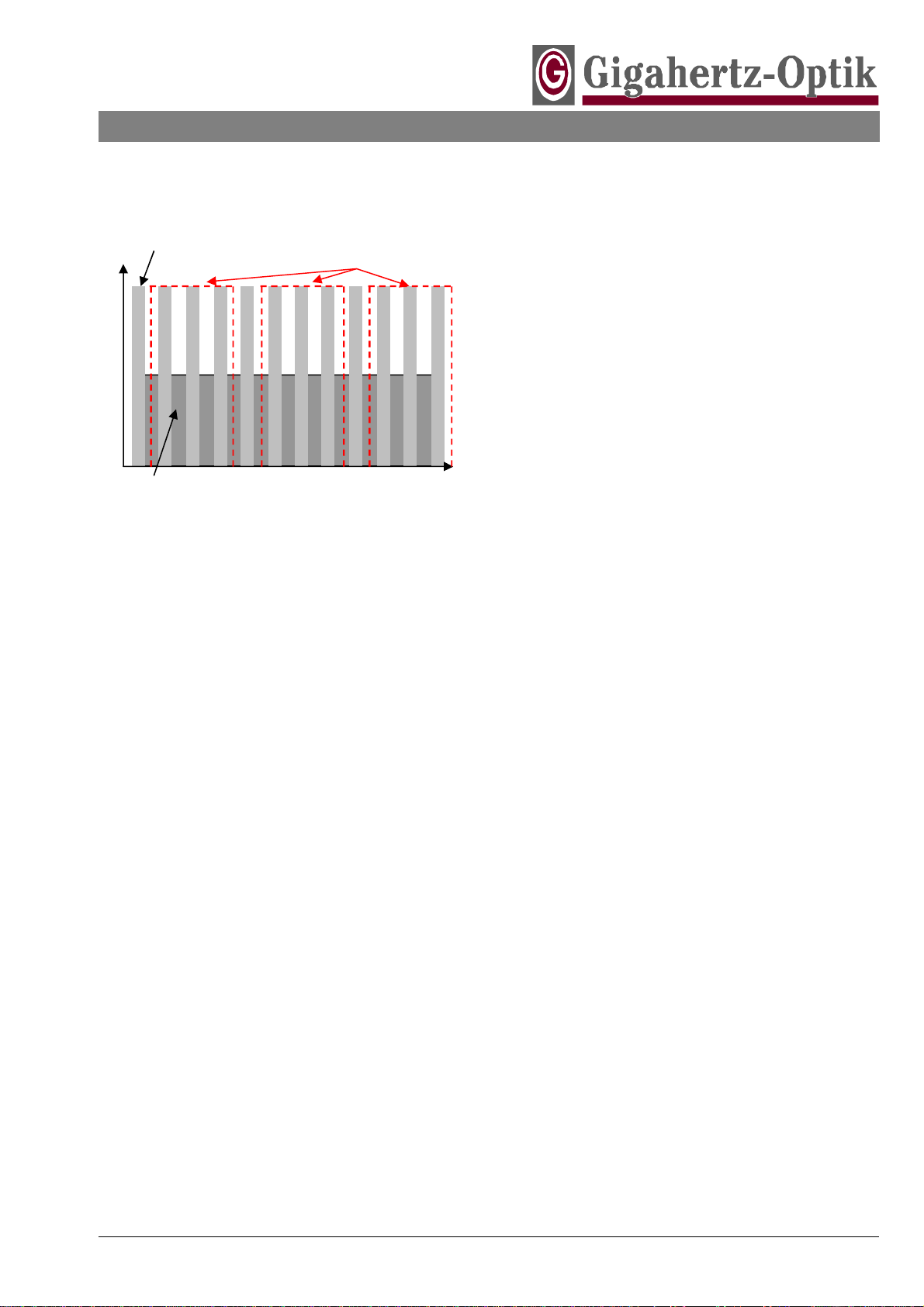

1.The substitutioneffect isone sourceofmeasurement

uncertainty.During calibration ofthespherephotometer

someofthe lightirradiated intothe spherewillexitthe

Picture6.3:Integrating SpherePhotometer

Picture6.4:Substitution Effect

Picture6.2:LightMeasurementQuantities

LuminousFlux LuminousIntensity

[ lm]

I[ cd]

Light Detector

Baffle

Calibration: DarkRoom

withoutRe-reflected Light Measurement: DUTReflec-

ted Light backintoSphere