MT82U 2D Scan Engine, Integration Guide, V0.1

TABLE OF CONTENTS

1

1.

.

I

IN

NT

TR

RO

OD

DU

UC

CT

TI

IO

ON

N .........................................................................................1

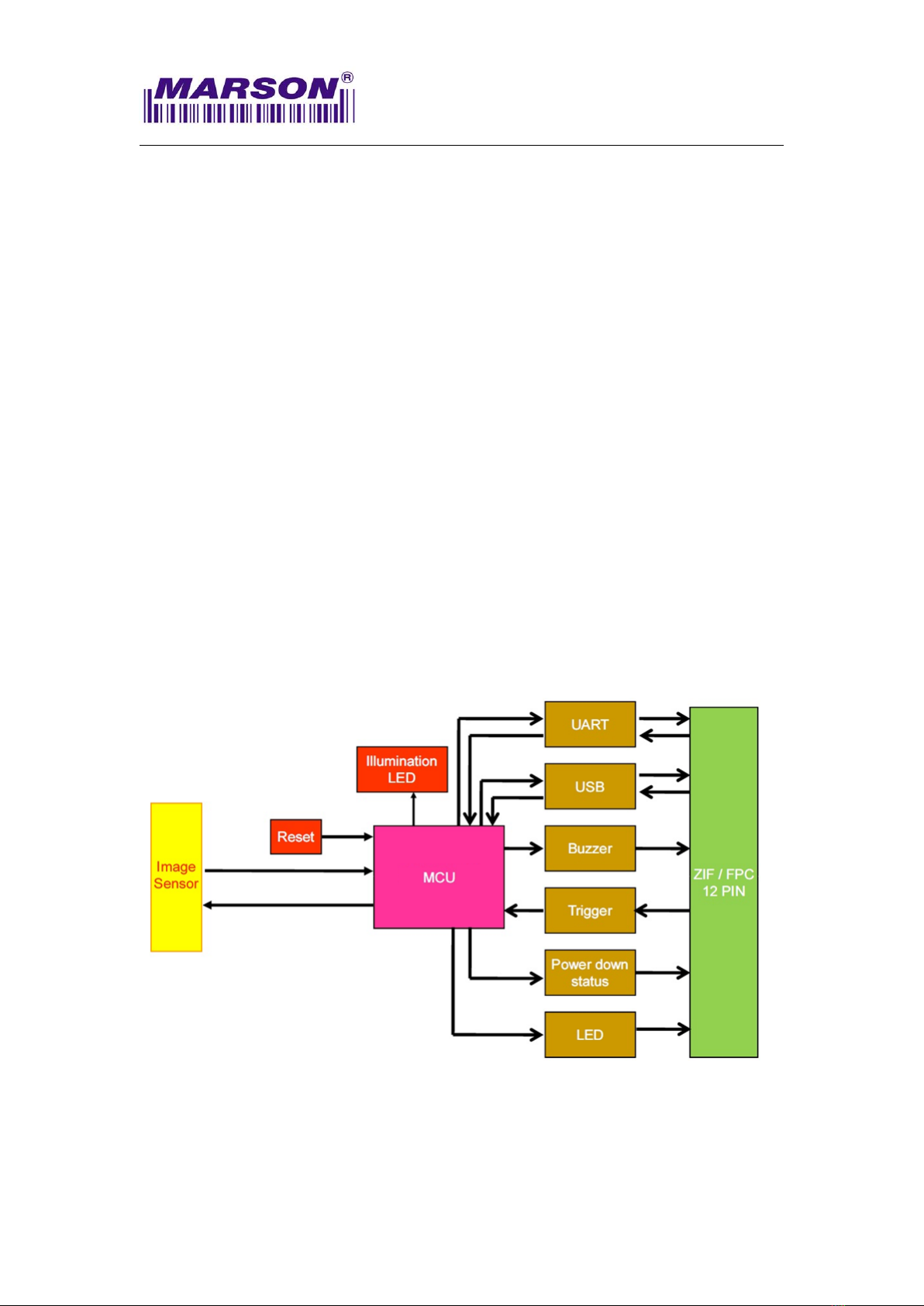

1-1. Block Diagram .................................................................................1

1

1-

-2

2.

.

E

El

le

ec

ct

tr

ri

ic

c

I

In

nt

te

er

rf

fa

ac

ce

e..............................................................................2

1

1-

-2

2-

-1

1.

.

P

Pi

in

n

A

As

ss

si

ig

gn

nm

me

en

nt

t .....................................................................2

1

1-

-2

2-

-2

2.

.

E

El

le

ec

ct

tr

ri

ic

c

C

Ch

ha

ar

ra

ac

ct

te

er

ri

is

st

ti

ic

cs

s ........................................................5

2

2.

.

S

SP

PE

EC

CI

IF

FI

IC

CA

AT

TI

IO

ON

NS

S .......................................................................................6

2

2-

-1

1.

.

I

In

nt

tr

ro

od

du

uc

ct

ti

io

on

n......................................................................................6

2

2-

-2

2.

.

T

Te

ec

ch

hn

ni

ic

ca

al

l

S

Sp

pe

ec

ci

if

fi

ic

ca

at

ti

io

on

ns

s .................................................................6

2

2-

-3

3.

.

I

In

nt

te

er

rf

fa

ac

ce

e............................................................................................8

2

2-

-3

3-

-1

1.

.

U

UA

AR

RT

T

I

In

nt

te

er

rf

fa

ac

ce

e ......................................................................8

2

2-

-3

3-

-2

2.

.

U

US

SB

B

H

HI

ID

D

I

In

nt

te

er

rf

fa

ac

ce

e..................................................................8

2

2-

-3

3-

-3

3.

.

U

US

SB

B

V

VC

CP

P

I

In

nt

te

er

rf

fa

ac

ce

e ................................................................8

2-4. Operation Method ............................................................................9

2

2-

-5

5.

.

M

Me

ec

ch

ha

an

ni

ic

ca

al

l

D

Di

im

me

en

ns

si

io

on

n ....................................................................9

2

2-

-6

6.

.

C

Co

on

nn

ne

ec

ct

to

or

r

S

Sp

pe

ec

ci

if

fi

ic

ca

at

ti

io

on

n .................................................................9

3

3.

.

I

IN

NS

ST

TA

AL

LL

LA

AT

TI

IO

ON

N ......................................................................................... 11

3

3-

-1

1.

.

E

El

le

ec

ct

tr

ro

os

st

ta

at

ti

ic

c

D

Di

is

sc

ch

ha

ar

rg

ge

e

C

Ca

au

ut

ti

io

on

ns

s................................................. 11

3

3-

-2

2.

.

M

Me

ec

ch

ha

an

ni

ic

ca

al

l

D

Di

im

me

en

ns

si

io

on

n .................................................................. 11

3-3. Window Materials ..........................................................................12

3

3-

-4

4.

.

W

Wi

in

nd

do

ow

w

S

Sp

pe

ec

ci

if

fi

ic

ca

at

ti

io

on

ns

s..................................................................13

3

3-

-5

5.

.

W

Wi

in

nd

do

ow

w

C

Ca

ar

re

e..................................................................................13

4

4.

.

R

RE

EG

GU

UL

LA

AT

TI

IO

ON

NS

S .........................................................................................14

5

5.

.

D

DE

EV

VE

EL

LO

OP

PM

ME

EN

NT

T

K

KI

IT

T.................................................................................15

6

6.

.

V

VE

ER

RS

SI

IO

ON

N

H

HI

IS

ST

TO

OR

RY

Y ..................................................................................16