Installation instructions

• Place the table at least 120 mm from other objects, eg,

adjoining tables, equipment, wall mounted shelves, etc to

avoid trap hazard.

• Make the top of the table level, ie, with the aid of the

adjustable feet on the frame.

• Test run the table and ensure that the drive axle works on

both sides.

Additional safety devices must be mounted in accordance with

instructions from Gigant if the table is to be placed in series.

When moving the table, never lift it by the top of the table

because the frame is too heavy.

Description

T e table is made for indoor use in an industrial or of ce

environment.

Conf guration

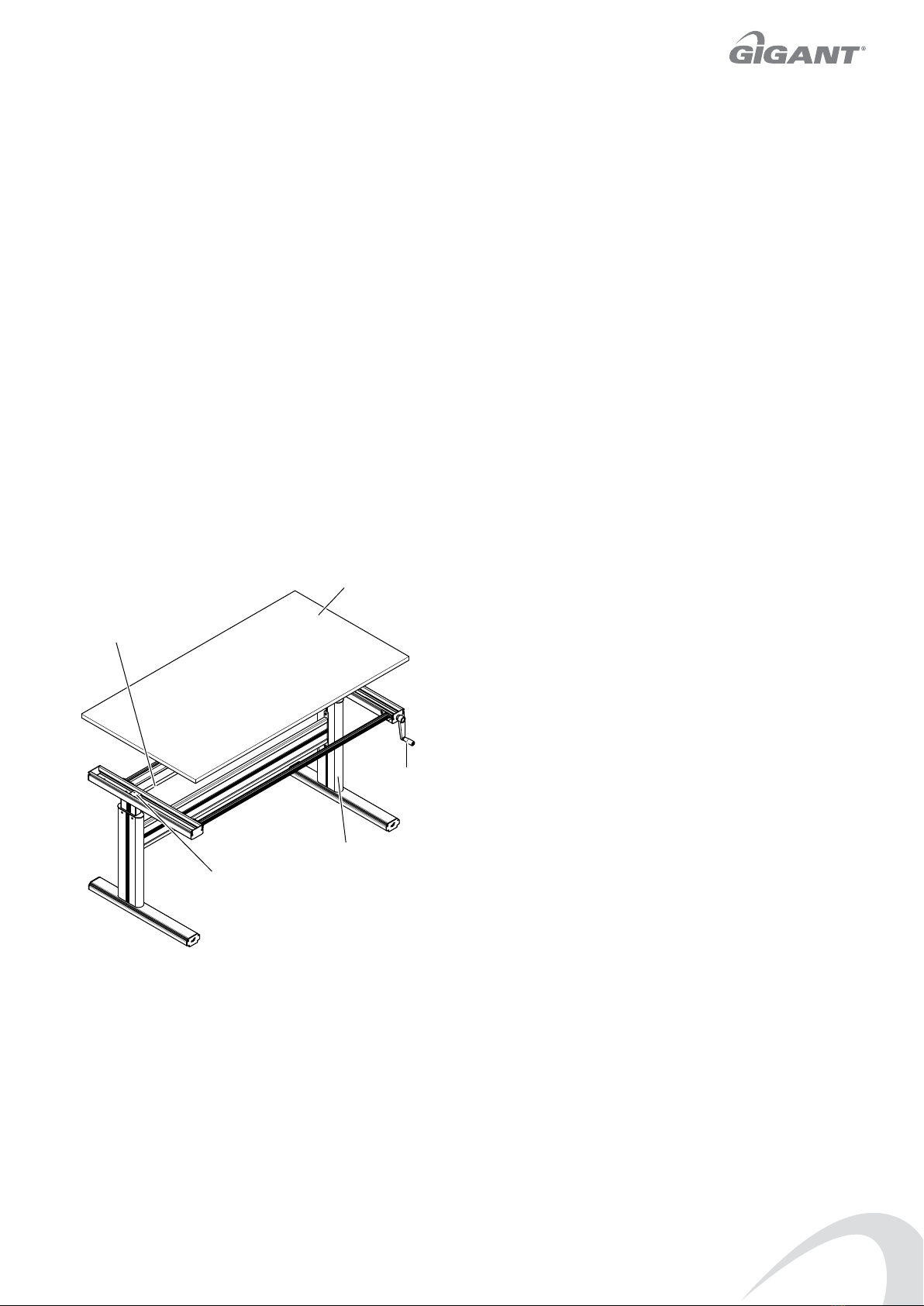

T e f gure shows the main parts of the table. T e table should be

completed with a suitable tapletop from Gigant:s product range.

Accessories

Accessories that are approved by Gigant for tables Flex 150 and

Flex 300 include the following:

• Set of wheels.

• Drawer and drawer suspension.

• Extensionframe for extensions.

• Tiltable tabletop.

• Undershelf.

Operating instruction

Raising and lowering the table

• Ensure that the table top, and anything placed on the table,

has clearance in relation to surrounding objects.

• Pull the crank forward so that it is clear of the table top.

• Crank to the desired height and then push the crank back

under the table top.

NB! When the table height is adjusted in right position, the table

has to be locked by pushing the crank under the table top.

WAr n In g !

Observe the danger of crushing between the table top or frame

and adjoining equipment when raising and lowering.

T e danger of tipping must be considered if load protrudes

beyond the extent of the frame.

For tables with a top that can be sloped:

WAr n In g !

Observe the danger of crushing if the table is f tted with an

adjustable sloping top.

Caution. T e top may not be sloped when loose objects are on

the table since this could otherwise result in personal injury.

Maintenance

All moving parts are lubricated at the factory and are therefore

free from maintenance.

Function

T e lifting function of the table is achieved by a crank that

transfers force via a gear wheel to the drive axle. T e drive axle in

turn is connected via gear wheels to a buttress threaded screw in

each of the telescopic legs.

Glide plates f tted in each telescopic leg ensure smooth and even

lifting action.

T e crank can be pushed in under the table top when not in use.

llstående

risk

.

rna.

eras enligt

v stativets

orsmiljö.

etteras med

erför kraften

apetsgängad

lyftrörelse.

AB följande

ustning.

bordskivan.

åsas genom

skiva eller

risken beak-

beaktas.

då detta kan

Vev

Kuggväxel mellan drivaxel

och trapetsgängad skruv

Teleskopben

Drivaxel

Crank

Gear wheel between drive axle

and buttress threaded screw

Table top

Telescopic leg

Drive axle