Mode 5

Mode 6

OPTIONAL FEATURES

-A RANGE OF MULTIPLEX OR ELECTRO-MECHANICAL CONTROL

PANELS

-REMOTE, ELECTRICAL BLADE STATUS INDICATION PANELS

-HEVAC INSTALLATION FRAME/DRY WALL FIXING FRAME

-ACCESS PANEL

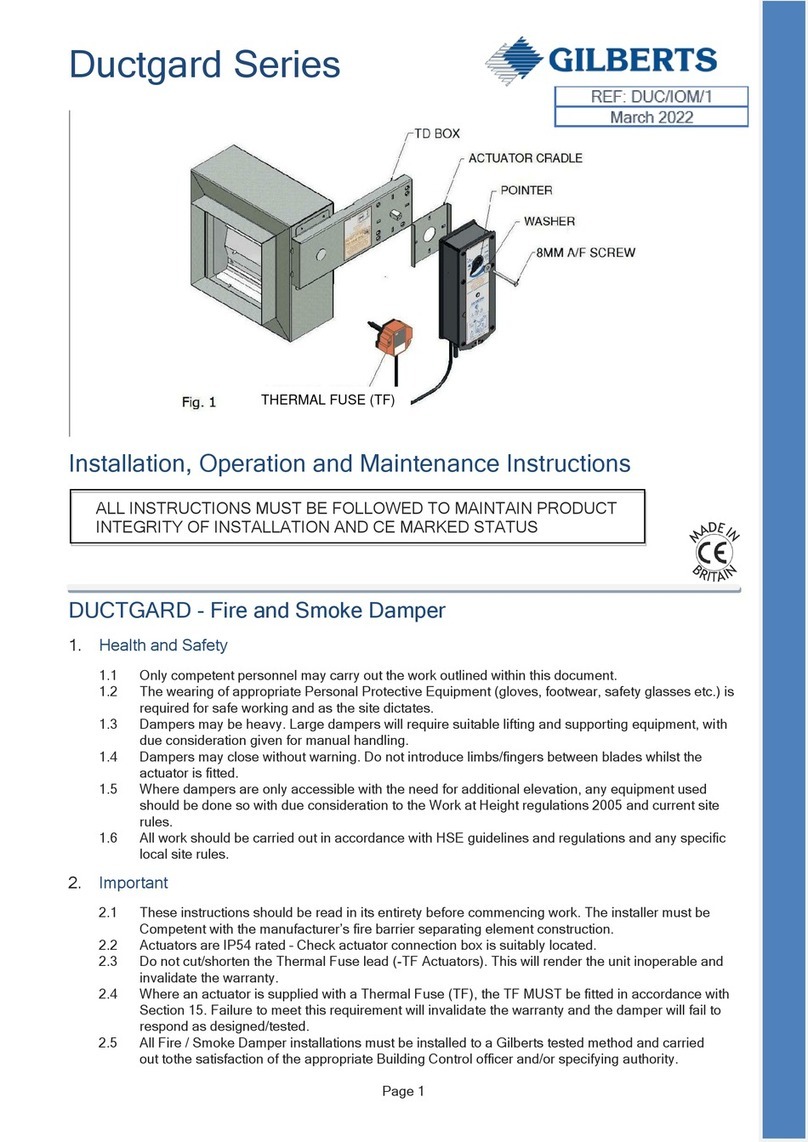

Description

Mode 5 is a fully automatic type of smoke and

fire damper and operates on the basis of fail

safe closure with automatic reset. It has been

designed to close in smoke and fire conditions

upon signal from a fire detection system or in

the event of an electro thermal fusible link

separating at a pre-determined temperature

(72°C standard).

Operation

Mode 5 is fitted with a square drive spring return

motor which will hold the damper open for as

long as the supply voltage is available.

Interruption of this supply will cause controlled

damper closure by way of the motors spring

return operation. In addition however, the

damper is also fitted with an electro thermal

fusible link which will separate at a pre-

determined temperature (72°C standard) and

close the damper irrespective of motor position.

All Mode 5 units are also fitted with a control

box which is situated on the dampers ductwork

extension and houses the integral PCB, status

indication L.E.D. and test facility. The test key

facility allows local checks to be made on the

damper operation.

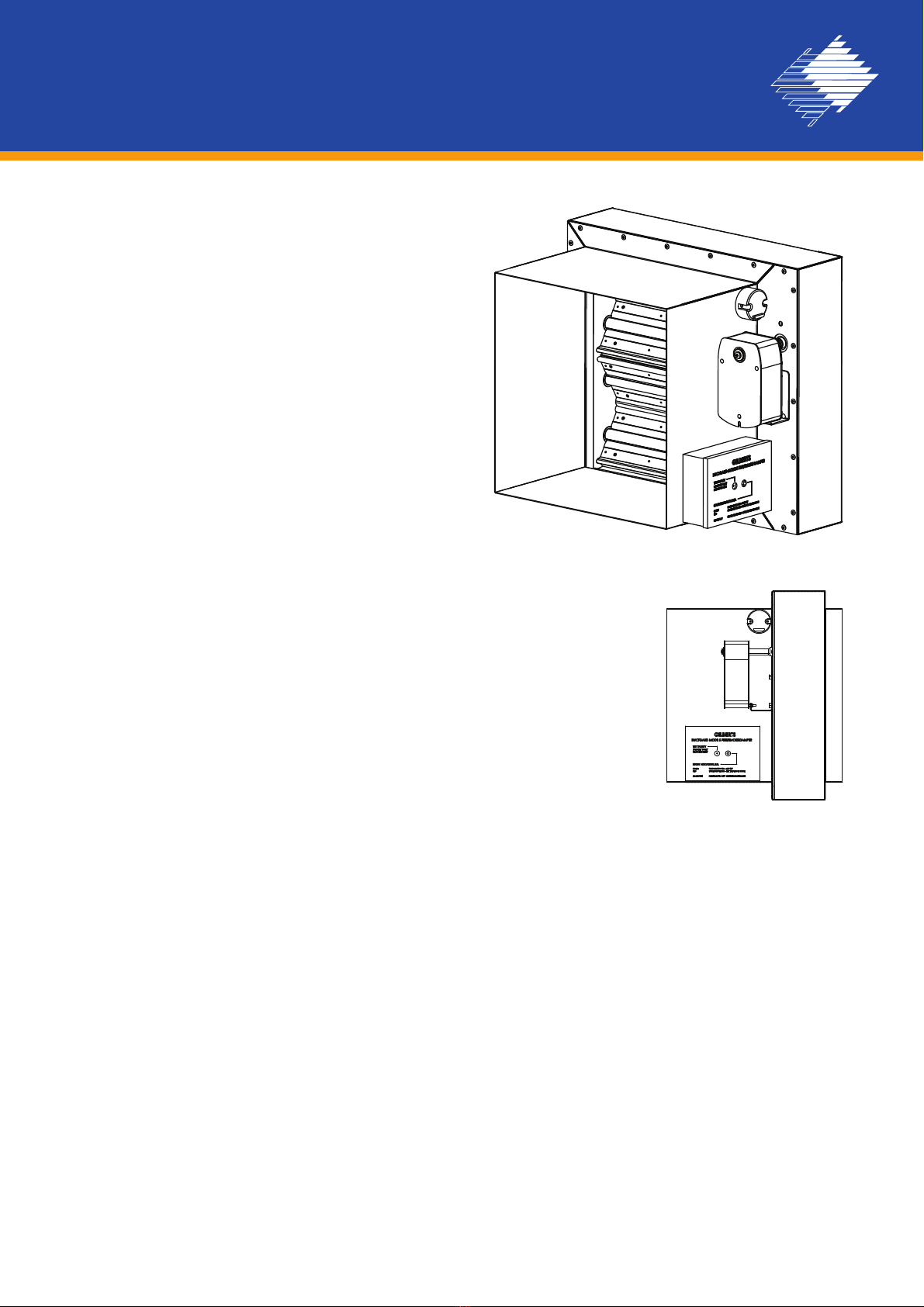

The L.E.D., provides the following diagnostic

checks:-

GREEN DISPLAY:- Power supply ON, unit set.

RED DISPLAY:- Power supply ON, but unit in

fail safe mode.

NO DISPLAY:- Power supply failure, unit in fail

safe mode.

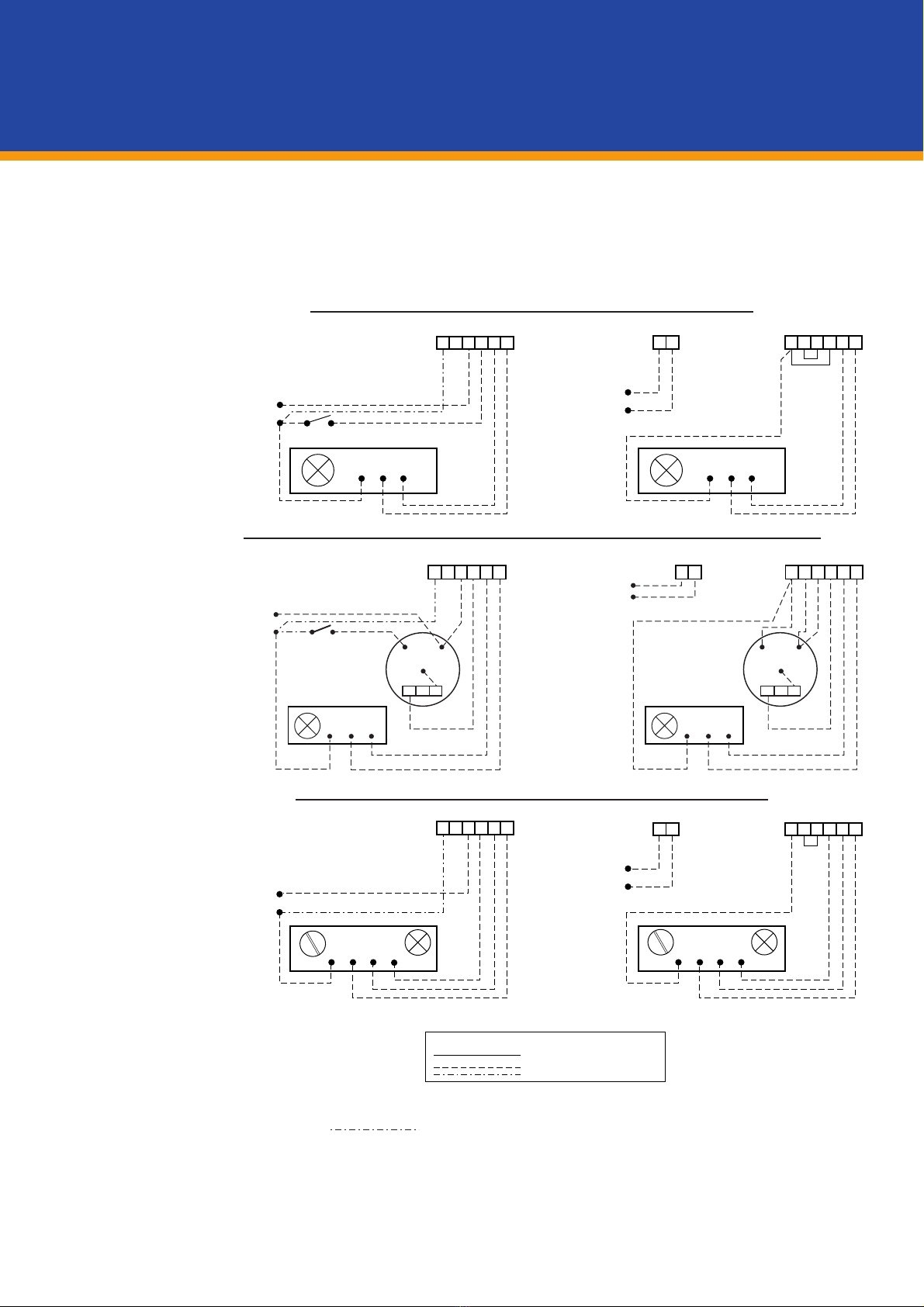

The control box also provides an interface for

remote status indication, smoke detectors and

RCP control (see page 11 and 12).

Control Options

A- 24v DC Power Supply

B- 240v AC Power Supply

Re-Set Procedure

Provided the fusible link is intact and the remote

or local test facility is not being utilised the

damper will automatically reset after an

interruption of the supply voltage. The motor will

take approximately 80 seconds to fully open the

damper.

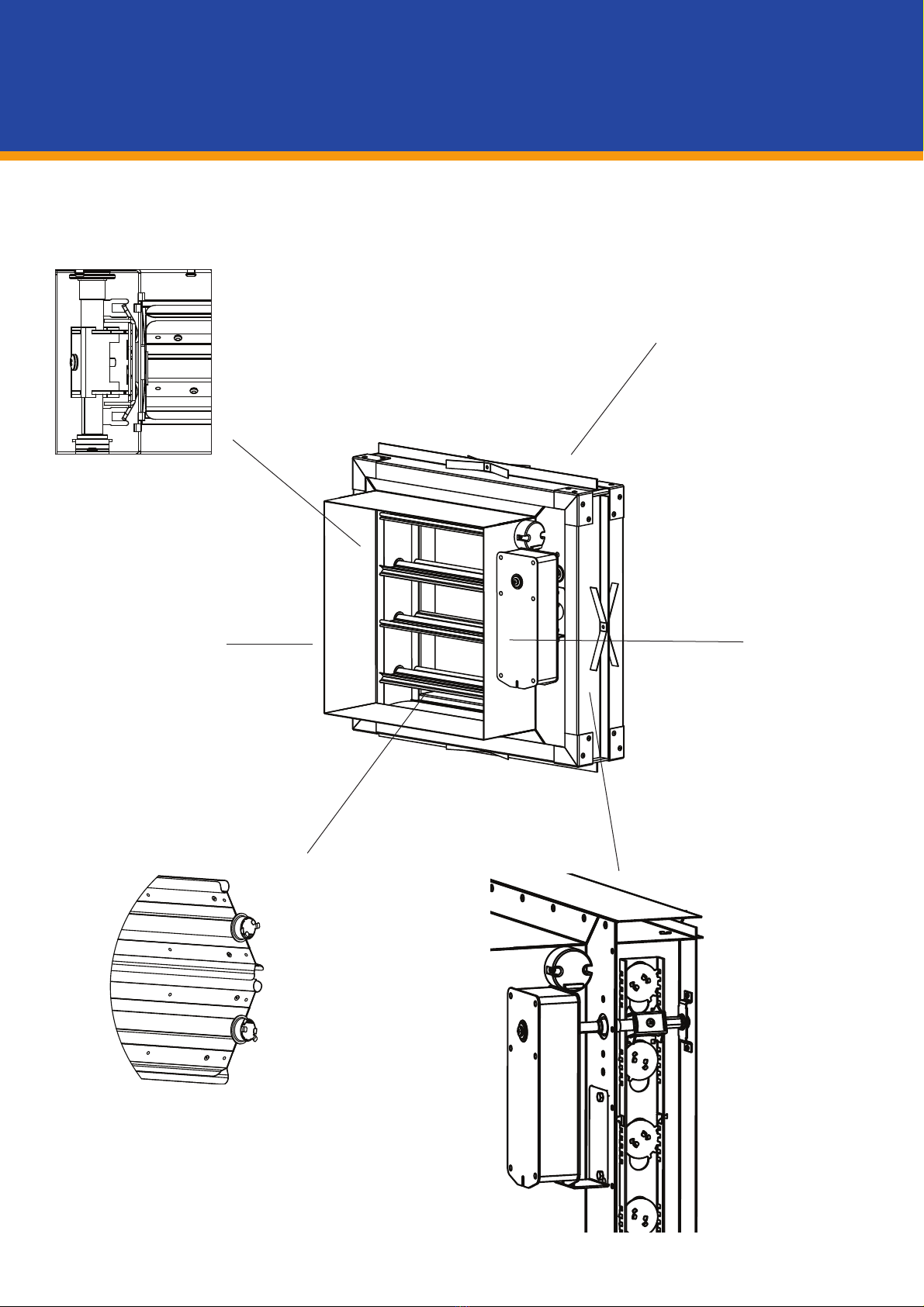

The LED indicator and test facility are housed in

a control panel mounted on the ductwork

connection sleeve. Fully assembled prior to

despatch they require only the external electrical

wiring connections to be made on site.

Mode 6 performs in exactly the same manner as

the Mode 5 except that the operation is reversed

and the unit is fail safe open. The motor sets the

unit in the closed position and the unit will only

open in the event of a signal from the fire

detection system, separation of the thermal

fusible link or operation of the key test facility.

Ordering procedure: Back cover.

4