7

EKOVENT AB We reserve the right to make changes 2021-03

Supporting construction - wall or floor in fire resistance class EI 60.

P-approval SC0848-13

Important! The smoke damper should always be installed with the blade

shaft horizontal..

Operation

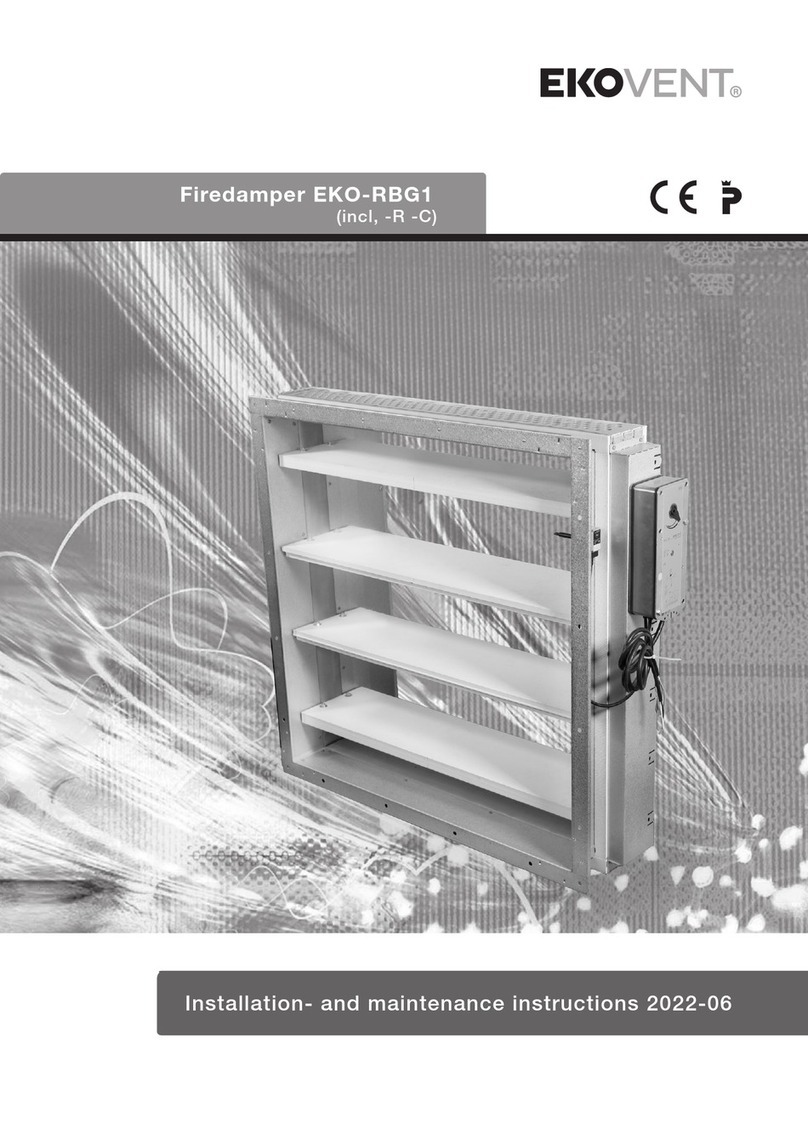

Fire damper EKO-SRB1 is a P- and CE

marked damper for re separation of hea-

ting, ventilation and air conditioning instal-

lations in buildings. EKO-SRB1 is always

supplied with an electric safety actuator

complete with thermal sensor that discon-

nects the power to the actuator if the tem-

perature exceeds 72 °C. The facility must

have a smoke detector which indicates an

alarm and which closes the re damper

and which must be connected to moni-

toring systems EKO-MKE/SKE, EKO-KE,

EKO-TME/TSE, MME/SME or equivalent.

Automatic function check takes place eve-

ry 48 hours (or at more frequent intervals),

malfunction is shown in the display.

Maintenance

External and internal control

At least every three years, check the elec-

trical wiring for actuators, end position

contacts and smoke detectors as well as

the damper cover so that no foreign de-

tails can prevent the damper blade from

moving. Also check the attachment of

the actuator, damper blade and sealing

strip so that no damage has occurred.

Also check that the corrosion protection

is intact.

Function control

Automatic: see above.

Manuell: Manual: Manual function check

can be performed from the central unit

menu. During installation, manual function

check can also be performed on the re-

spective slave unit (applies to EKO-MKE/

SKE, EKO-TME/TSE, MME/SME). Manual

function check can be done by pressing

the test button for automatic function

check which is located on the front of

the monitoring unit (applies to EKO-KE).

Powerless damper closes. Check that

the damper is fully open during opera-

tion, closes and opens completely during

testing and closes completely in the event

of a power failure. Otherwise follow the

instructions for monitoring systems EKO –

MKE/SKE, EKO-KE, EKO-TME/TSE, MME/

SME.

Cleaning

We advocate preventive maintenance of

the damper according to the facilities

needs. Clean the damper blade and dam-

per (inside) with a brush, vacuuming or

wiping. NOTE! Water or other liquids must

not be used. Regular testing according to

the P-approval.

Note!

After inspection, the fire damper must

be left in normal working position.

Warning!

Never keep your hands inside the dam-

per when it closes. Risk of crushing

injuries.

Spare parts list

Actuator, see type designation of the ac-

tuator.

Operation and maintenance