User Manual 5.3 (2018-07) 3Subject to change Series FR92

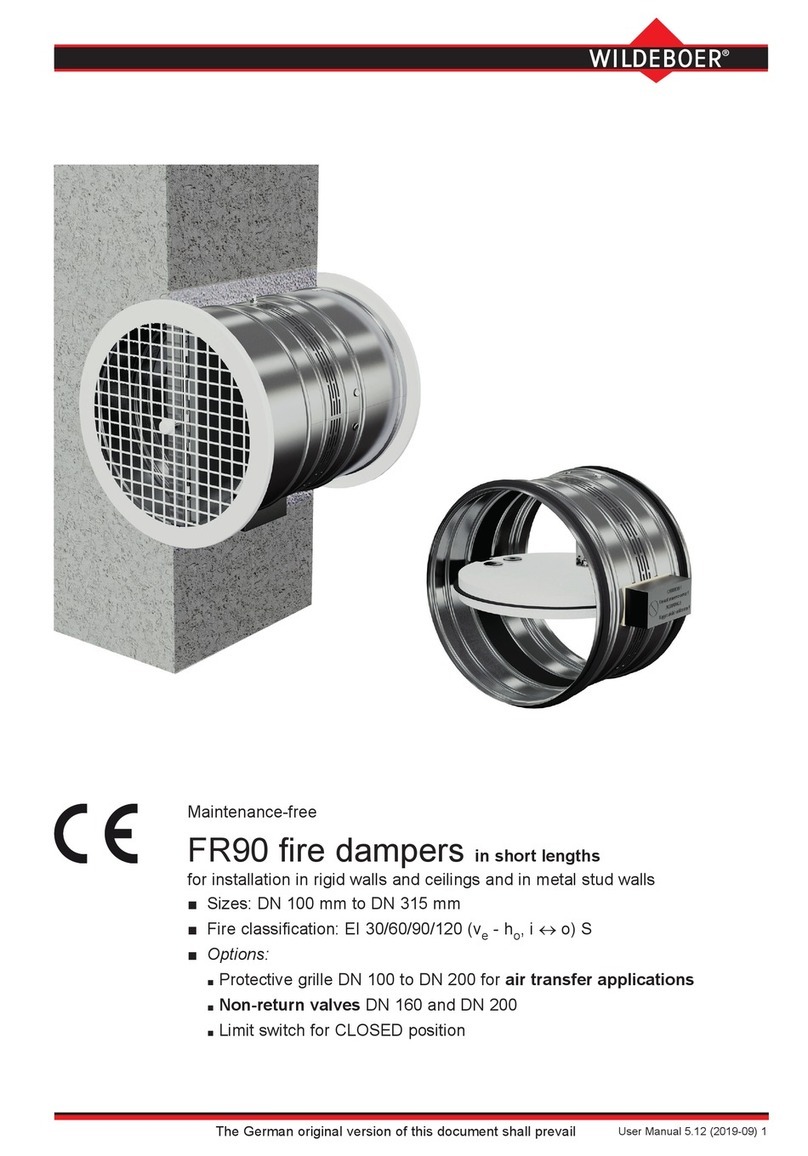

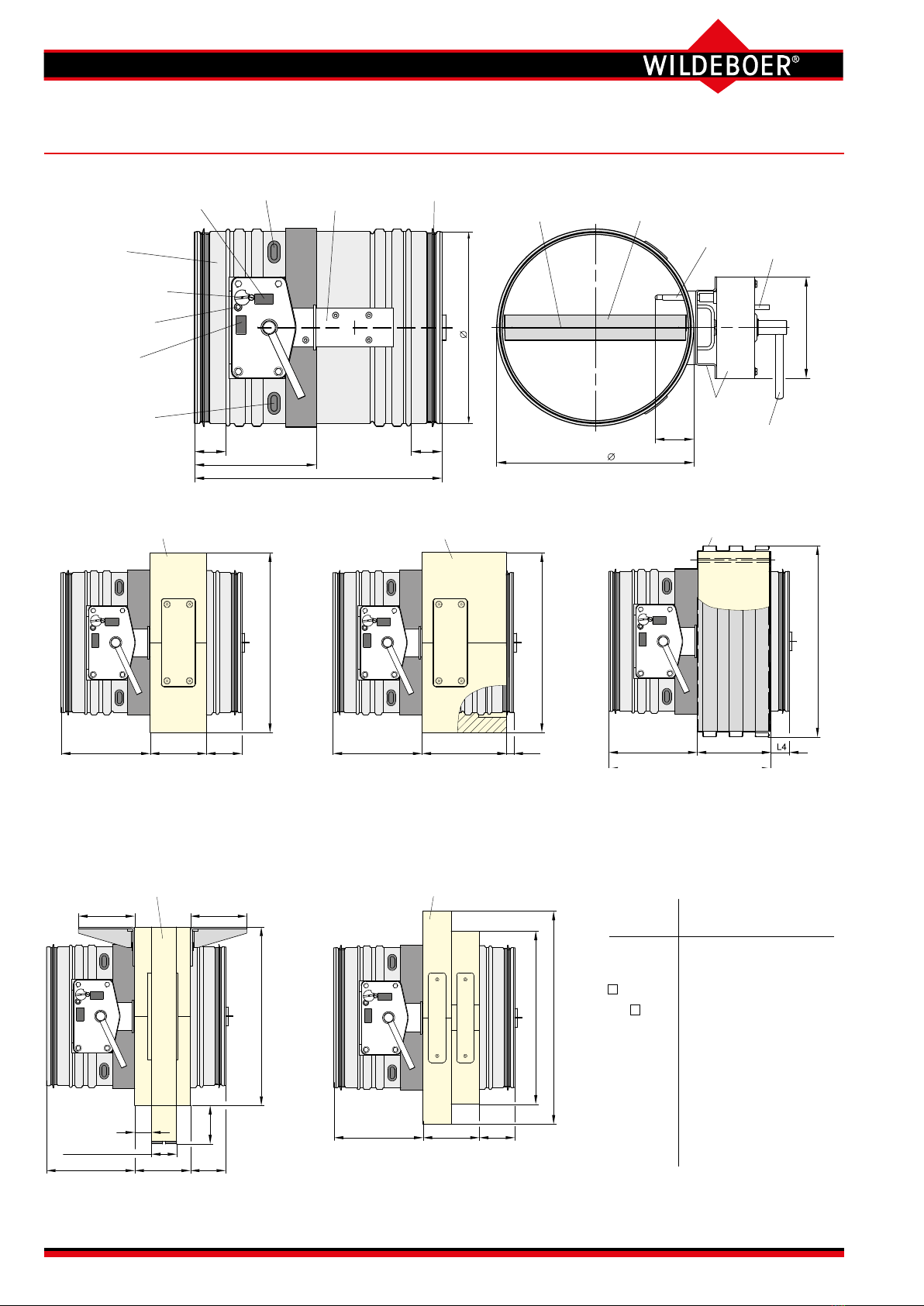

FR90 re dampers

Description

All-round single-piece galvanized sheet steel casing.

Casing tightness class C according to EN 1751.

Moulded push-t connections with lip seals for spiral

duct according to DIN 24145, for exible pipe and for

similar ducts of ventilation and air conditioning systems.

All-round press-moulded beading over the whole length

of casing ensures necessary strength and free move-

ment of the damper blade even with large dimensions.

Low pressure drop and a very low noise level are thus

achieved.

Replaceable damper blade made of high-tempera-

ture-resistant, abrasion-proof calcium silicate with

wear-resistant elastomer seals. Damper blade leak tight-

ness class 3 according to EN 1751.

Option: Casing with powder coating. ⇒ see page 6

Option: Damper blade with metal cover (not replaceable)

made of galvanized steel or 1.4301 stainless steel.

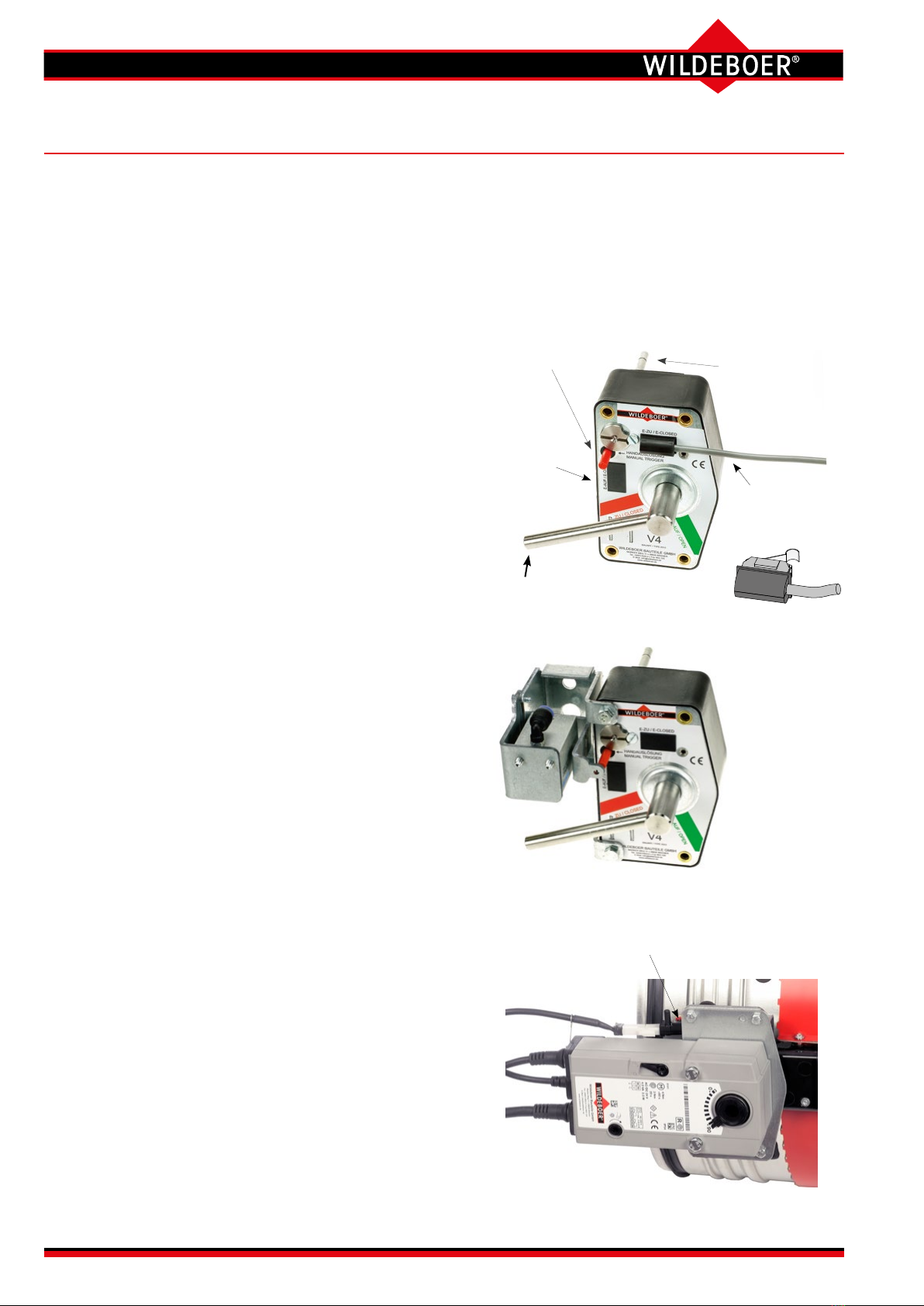

Enclosed, maintenance-free drive mechanism in the

area of the casing wall as a self-locking transmission

for break-proof torque transmission. Sealed drive axles

made of stainless steel, with red metal bearings. Ther-

mal release mechanisms for 70°C or 95°C nominal tem-

perature. The operation units can be actuated manually

or electrically. ⇒ see pages 4 and 5

Release mechanisms, operation units and electric actu-

ators are enclosed and with a spring return. They are

maintenance-free, can be connected in a form-locking

or force-tting manner, are easy to replace and can be

easily retrotted as required.

For installation with horizontal or vertical damper blade

axles and in intermediate positions. Air ows are pos-

sible from each connection side.

Connection to ventilation ducts made from non-combus-

tible or combustible materials is possible, also protective

grille.

Installation spacings from 15 mm possible.

Maintenance-free FR90 re dampers according to EN 15650

Fire classications: EI 30/60/90/120 (ve - ho, i ↔ o) S C10ooo

Declaration of performance: DoP no.: CPR/FR90/003

EU Declaration of Conformity according to Directive 2014/34/EU for

use in potentially explosive atmospheres

Environmental Product Declaration ISO 14025, EN 15804:

EPD-WWB-20130082-IBA1-DE

Additional national approvals in

Germany:

• Building materials: Z-56.4212-993

FR90 re dampers are essentially

made from non-combustible build-

ing materials.

• Air transfer applications:

Z-6.50-2133

Z-19.18-2241

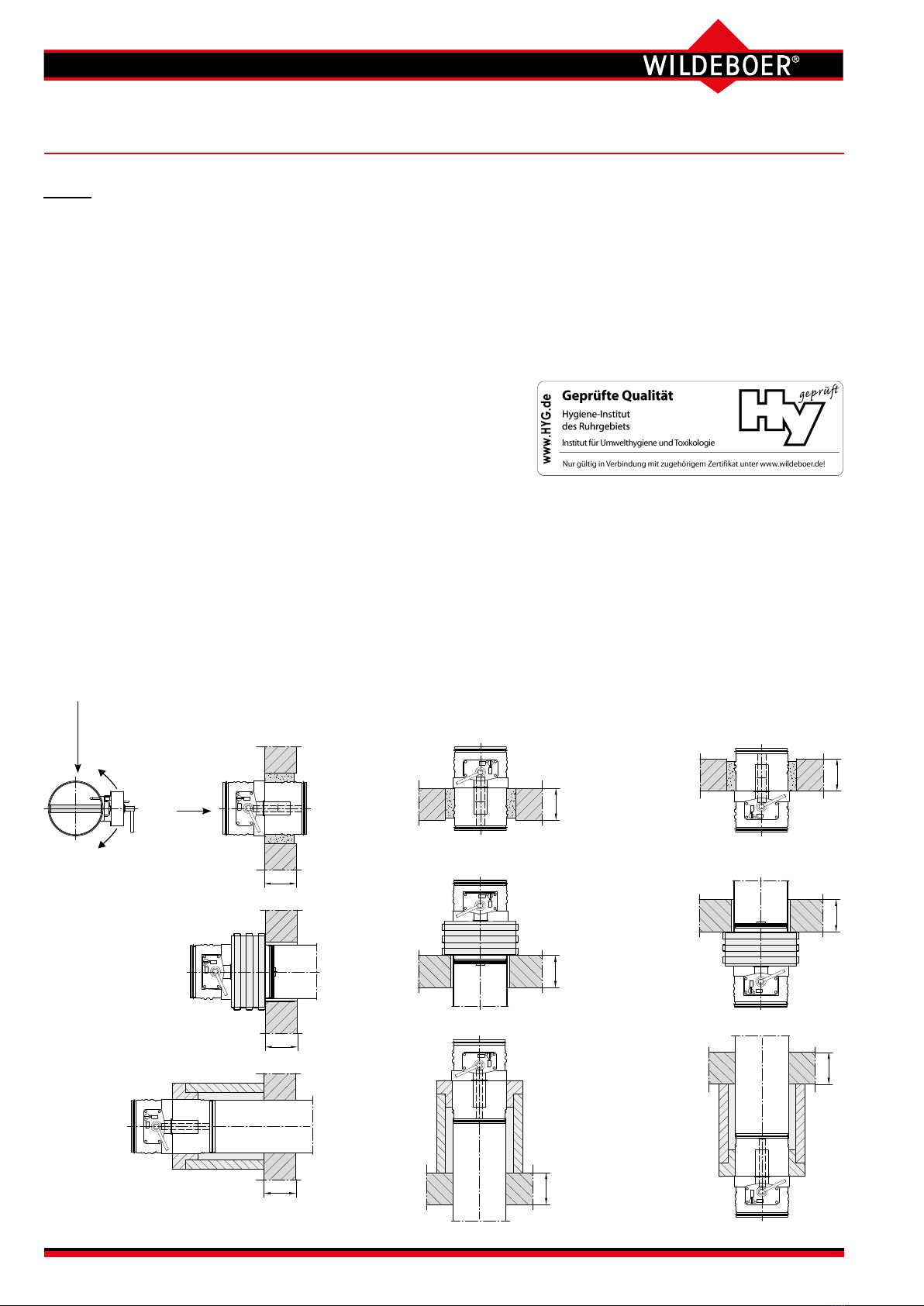

•Circular installation subframe RR (RR100, RR150) for

simplied installation in circular installation openings.

Only up to DN 315! ⇒ see pages 7, 8, 13, 14, 22, 42 to 44

•

Rectangular installation subframe RE (RE100,

RE150) for simplied installation in rigid walls and

ceilings and in metal stud walls with cladding on both

sides.

⇒ see pages 7, 8, 13, 14, 20 to 22, 42 to 44

• With rectangular installation subframe RH (RH100,

RH150) for installation in wooden walls and wooden

ceilings. ⇒ see pages 7, 8, 28 to 31, 42 to 45

• Rectangular installation subframe RH150 for instal-

lation in ceilings with steel frames.

⇒ see pages 7, 8, 33, 34, 42 to 45

•Mounting frame AE for mounting on rigid walls and

ceilings and walls with cladding on one side and with

or without metal studs.

⇒ see pages 7, 8, 15, 26, 27, 35, 42 to 44

•Installation subframe ER6 for sliding ceiling connec-

tions with drops of up to 40 mm in metal stud walls

with cladding on both sides.

⇒ see pages 7, 8, 23 to 25, 42, 43

•Mounting frame RV for connection to ventilation

ducts with re resistance period. Installation remote

from rigid walls and ceilings and metal stud walls.

⇒ see pages 7, 8, 36 to 39, 42 to 45

Nominal sizes [mm] DN:

100 - 125 - 140 - 160 - 180 - 200 - 224 - 250 - 280 - 315 - 355 - 400 - 450 - 500 - 560 - 630 - 710 - 800

Options:

FR90 re dampers in these sizes achieve re resistance periods of up to 120 minutes if they are installed in accordance with

the following stipulations. Installation types in, on or remote from rigid walls and ceilings or metal stud walls, in wooden walls and

ceilings and in ceilings with steel frames with a minimum thickness and re resistance period. If the walls, ceilings have a re

resistance period of less than 120, 90 or 60 minutes, the re resistance period of the FR90 re dampers is reduced accordingly;

partly if the minimum thickness is lower.