www.h-v-c.com

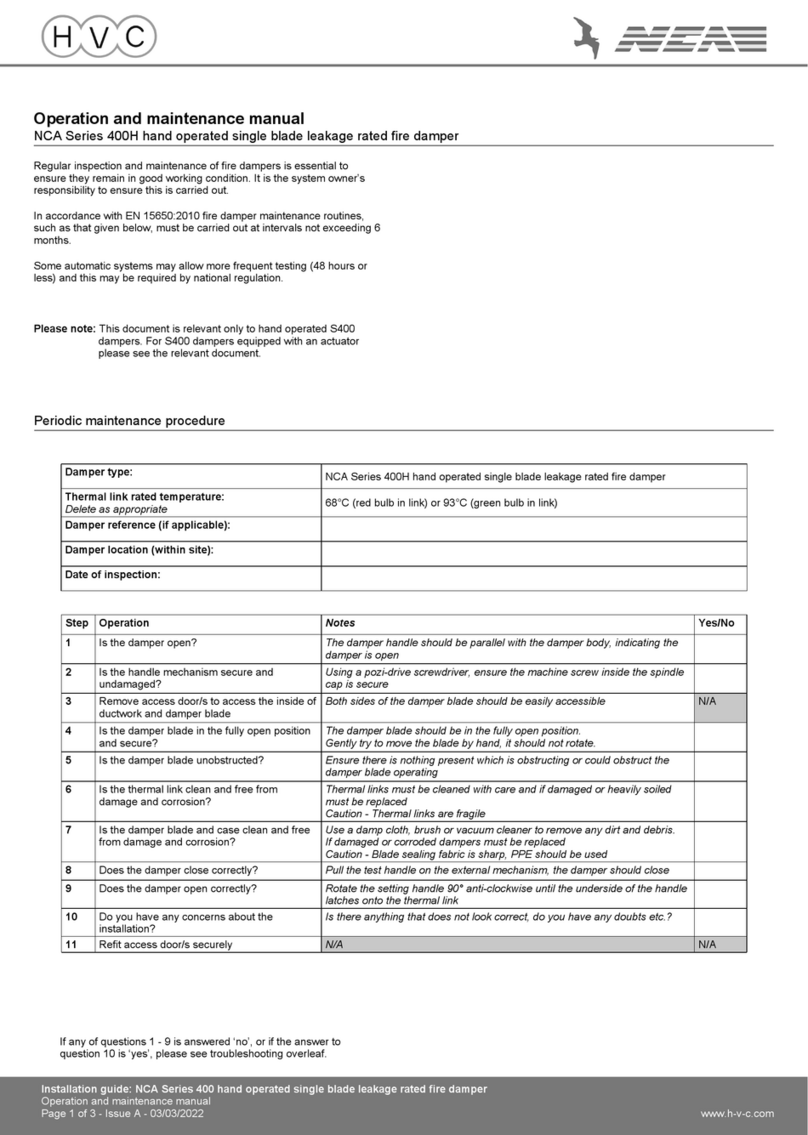

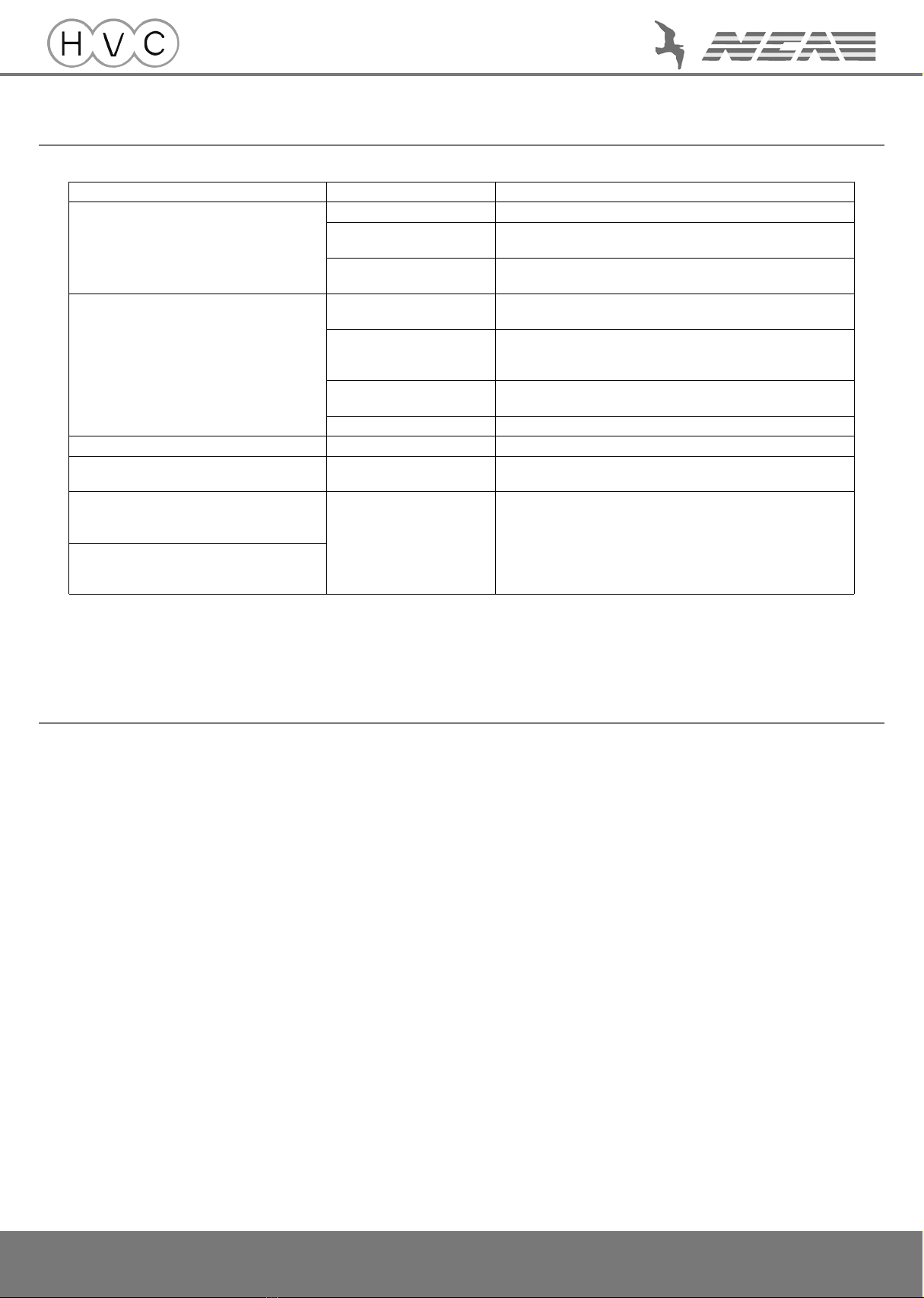

Symptom Possible causes Action

The thermal probe's LED is not lit and the

damper is closed

No power or incorrect supply Check supply

Thermal probe has been

tripped or is faulty

Replace thermal probe tripping element, part reference

‘Belimo ZBAT72’

Actuator faulty or damaged Replace actuator

See below: 'Actuator removal and replacement procedure'

Damper blades operating in unison but not

fully opening or closing

Damper motion obstructed by

debris

Remove debris

Ensure no damage has been caused to damper

Actuator fitted incorrectly Remove and refit actuator correctly

See below: 'Actuator removal and replacement procedure'

Ensure no damage has been caused to damper

Damper seized Lubrication required

See below: 'Lubrication procedure'

Mechanical failure Contact HVC

Damper blade/s loose and not synchronised Mechanical failure Contact HVC

Damper is noisy or judders during operation Lack of maintenance Lubrication required

See below: 'Lubrication procedure'

Multiple section unit only

The thermal probe's LED is lit but the

dampers are closed

Relay box fault Contact HVC

Multiple section unit only

Damper sections not synchronised

(e.g. one section closed, one section open)

Installation guide: NCA Series 700 motorised leakage rated fire damper

Operation and maintenance manual

Page 2 of 2 - Issue A - 27/05/2020

Actuator removal and replacement procedure

1. Isolate and disconnect existing actuator from power supply (or

multiple fire damper relay box), actuator will spring closed.

2. Remove actuator from damper (4 qty M6 bolts), retain bolts.

3. If the unit is a single section, remove thermal probe from

ductwork (2 qty screws). If unit is a multiple section do not

remove the thermal probe.

4. Ensure the new actuator is in its closed position by inserting

the winding handle (supplied) and relieving the factory set

spring tension.

5. Ensure the damper is still in its closed position.

6. With the side labelled ‘R’ of the actuator facing away from the

damper (the ‘L’ side towards the damper), slide the actuator

onto the 12mm square spindle.

7. Using the retained M6 bolts fit the new actuator to the damper,

and the thermal probe to ductwork if one was previously

removed.

8. Connect the new actuator to an appropriate power supply (or

multiple fire damper relay box), allow the damper to open and

then conduct a cycle test as per steps 9 and 10 of the periodic

maintenance procedure.

Troubleshooting

Additional procedures

Lubrication procedure

1. Remove access door/s to access the inside of ductwork and

damper blades

2. Clean damper if required following step 7 of the periodic

maintenance procedure.

3. Depress the stainless steel side seals, and apply a small

amount of light oil (WD40 spray grease recommended) directly

into the blade axle bushes.

4. If required a light application of oil can be made to the blade

ends and stainless steel side, top and bottom seals.

5. Remove any excess oil with a cloth.

6. Conduct a cycle test as per steps 9 and 10 of the periodic

maintenance procedure and observe whether the operation

has improved. Several reapplications/cycles may be required

to permit the lubricant to reach all required areas.

Contact HVC if the above does not solve your problem.

Periodic maintenance procedure overleaf →