Glastender, Inc. • 5400 North Michigan Road • Saginaw, MI • 48604-9780

800.748.0423 • 989.752.4275 • Fax 989.752.4444 • www.glastender.com 1

Topic Page

Warranty.................................................................................................................... 1

What is a glasswasher? ............................................................................................. 2

Uncrating Instructions and Equipment Checklist..................................................... 3

Main Section - Top View.......................................................................................... 4

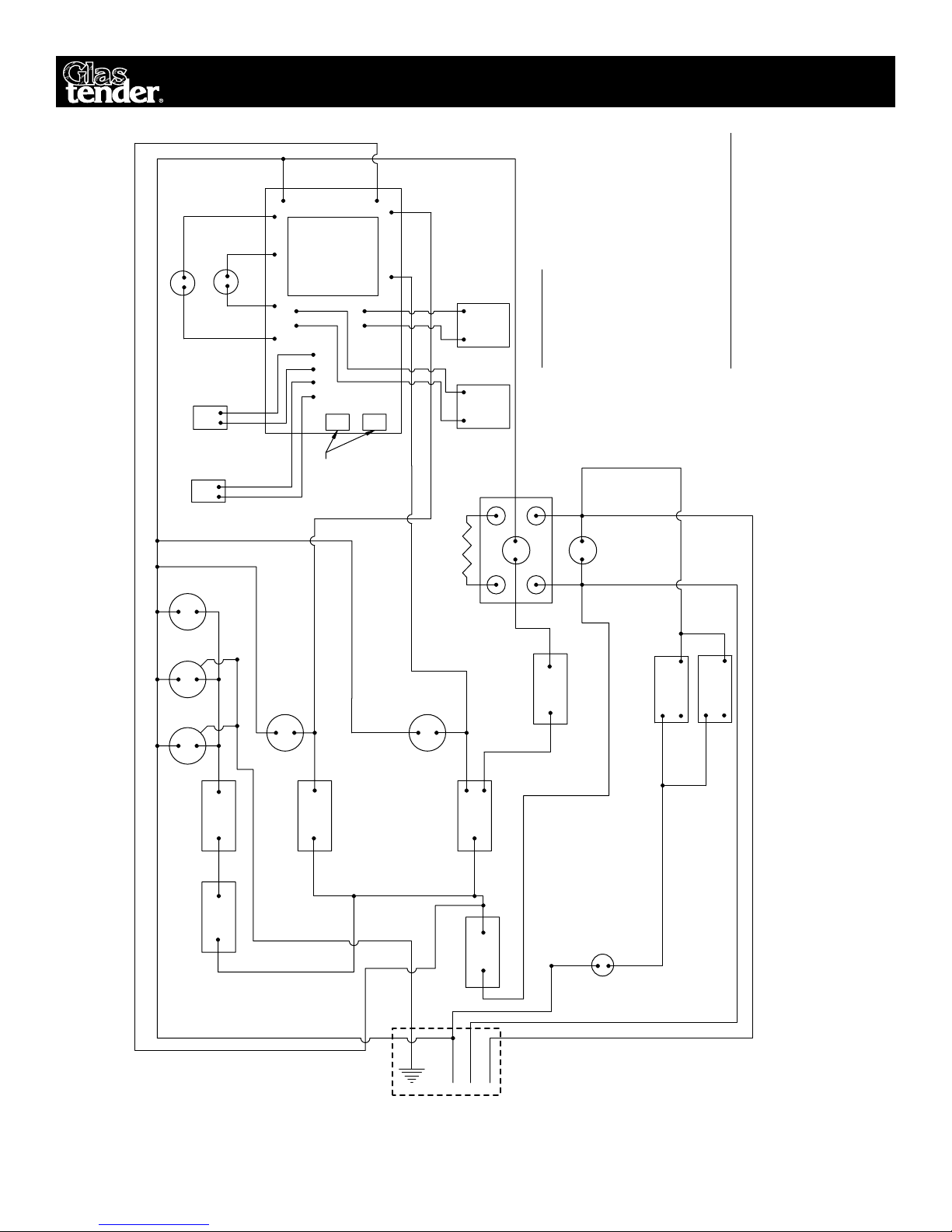

Wiring Diagrams

Manufactured Before Jan. 2003 ...................................................................... 5

Manufactured After Jan. 2003 ......................................................................... 6

Utility Requirements and Connections..................................................................7-8

Start-Up Instructions..............................................................................................8-9

Peristaltic Pump Adjustments .............................................................................. 9-10

Useful Information About Water, Detergent and Sanitizer .................................... 11

How to Operate the Glasswasher ........................................................................... 12

How the Glasswasher Operates .........................................................................12-14

Tips for Trouble-Free Operation............................................................................. 14

Important Information About Chemicals................................................................ 15

Diagnosing Poor Wash Results............................................................................... 16

Cleaning Instructions .........................................................................................17-18

Troubleshooting Guide ......................................................................................19-21

Index

IMPORTANT!!

Attention Refrigeration Service Companies

Please review the important warranty information on this page. If you believe a

service call should be covered by the factory, please call the factory for authorization

between 8AM and 5PM EST, Monday through Friday.

warranty statement

LABOR: Glastender, Inc. warrants all products to be free of defects in

material and workmanship. In established areas, a start-up and a 90-

day labor warranty are included with glasswasher models GT-24 and

GT-30. The GT-18 series glasswashers include a 90-day labor warranty.

Self-contained refrigeration models, except beer line chillers, include a

1-year labor warranty, for the duration of one year from date of instal-

lation or up to 18 months from date of factory shipment, whichever

occurs sooner. For warranty labor claims beyond 15 months from the

date of factory shipment, proof of date of installation or occupancy must

be provided. Authorization for labor must be obtained from Glastender

within the warranty period and prior to the service being performed.

Labor warranty applies to the United States and Canada only.

PARTS: Within one year from date of installation, or 15 months from

date of factory shipment, whichever occurs sooner, Glastender, Inc.

will replace any part or assembly found defective under normal use and

service. Field replacement parts include a warranty of 90 days from date

of installation. All self-contained refrigeration models include a 5-year

compressor warranty.

A warranty claim form MUST accompany all returned defective parts or

assemblies. This form MUST be completed in full. Failure to do so may

result in delay or denial of credit. Any defective part or assembly must

be returned to Glastender, Inc., Saginaw, Michigan, with all transporta-

tion and delivery charges prepaid. Warranty repairs or replacements will

be shipped FOB factory in Saginaw, Michigan.

The warranty does not cover equipment subjected to accidents, freight

damage, alterations, improper power and/or plumbing hookups, improp-

er chemical use, general misuse, or lack of routine required maintenance

as determined by Glastender, Inc.

No representative, distributor, dealer, or any other person is authorized

to modify this warranty. This warranty replaces all other written or

verbal warranties.

NOTE: Glastender, Inc.’s policy of constant quality improvement

means that prices, specifications, and policies are subject to change

without notice. Questions regarding this warranty should be directed to

Glastender’s Customer Service Representative.

03/01/07