Congratulations on your purchase of a Glidecam X-10 Camera Stabilization System.

In order to use the X-10 system, it is best to have a basic understanding of how the

system works in advance. So please make sure you read this section before trying

to setup and operate the X-10 Camera Stabilization System.

The X-10 Camera Stabilization System is designed to allow you to walk, run, go

up and down stairs, shoot from moving vehicles and travel over uneven terrain

without any camera instability or shake, when used with the GLIDECAM XR-

SERIES or GLIDECAM HD-SERIES (not included). The GLIDECAM XR-SERIES

and GLIDECAM HD-SERIES are generally used as hand-held camera stabilizers;

however, they can also be used with the X-10, and when they are, they are referred

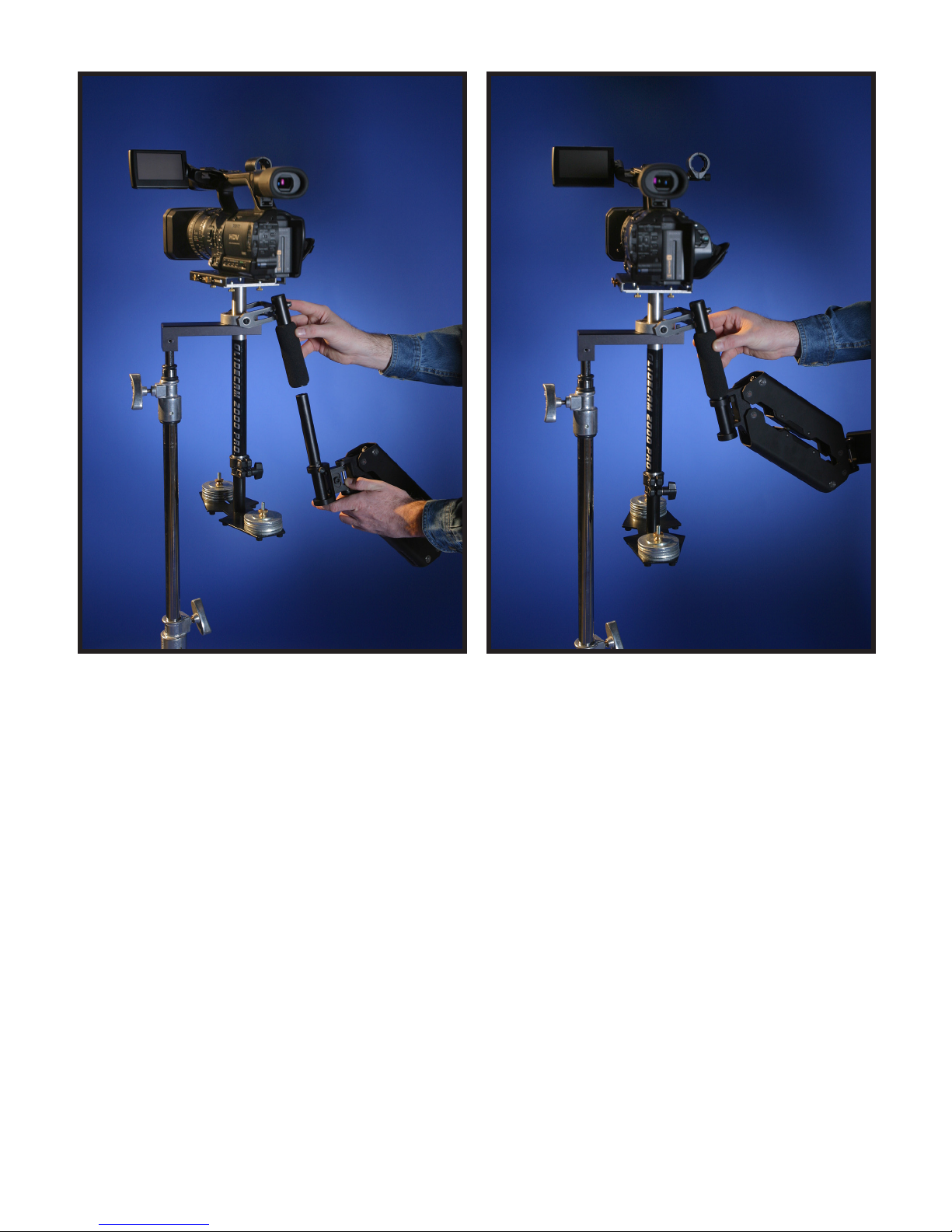

to as a SLED. The SLED carries your camera and is attached to the end of the

SPRING-LOADED SUPPORT ARM, which, in turn, is attached to the GLIDECAM

SUPPORT VEST.

When using the GLIDECAM XR-SERIES or GLIDECAM HD-SERIES in hand-held

mode, your arm is carrying the weight of the SLED. However, when the XR-SERIES

or HD-SERIES are used with the X-10, it is the X-10’S SPRING-LOADED SUPPORT

ARM that carries the weight of the SLED. Because of this, you will now be able to

shoot for extended periods of time, whereas before, the stress associated with hand

holding the SLED reduced your shooting time.

While the X-10 is in essence a very simple device, its simplicity doesn’t lend ease in

answering that often asked question, “how does it work?” To answer this question

completely would require delving into Newtonian Physics and Classical Mechanics.

We would have to explain - center of gravity displacement, inertia, reduced friction

and angular motion reduction etc. However, a quick answer reveals the X-10 works

by “isolating” your body’s motion from your camera, while your camera is balanced in

an isolated and relatively motionless state.

The X-10 requires practice and understanding to achieve professional looking results.

We highly recommend that the user read this manual thoroughly before setting up

and operating the X-10. Doing so will save you time, and will minimize the risk of

damage to your camera or the X-10. It is important to perform and follow the Setup

and Operation’s procedures in the proper sequence, so as to avoid both frustration

and a possible accident.

If you need technical assistance, you can page our Technical Support Line at 1-508-

830-1414, between the hours of 10:00 AM and 5:00 PM, Eastern Standard Time,

Monday through Friday. We’re sure that once you have your X-10 up and running,

you will nd years of enjoyment with it.

#1 INTRODUCTION

3